Removing the lock mechanism from a GE Master 2 Mobile

by

Ralph Hogan W4XE

In my repeater conversion of a GE Master 2 mobile,

I remove the key lock mechanism. I bring out the controller cabling and

receiver RF cable through the hole left by the key lock mechanism.

Iíve heard tales of hams busting off the slider

mechanism in order to get the lock out. Donít bust the slide bar! It

just takes a paper clip!

It took me a while my

first time to get it out, you have to be part lock smith which I am not.

Iíve detailed the steps below. In less than 5 minutes, you can have it

removed.

Take a large sized paperclip and unbend it out in

the shape below. Make a 90 degree bend at the tip, about 3/8" long.

-----------------------------------

(_______) | 3/8" long

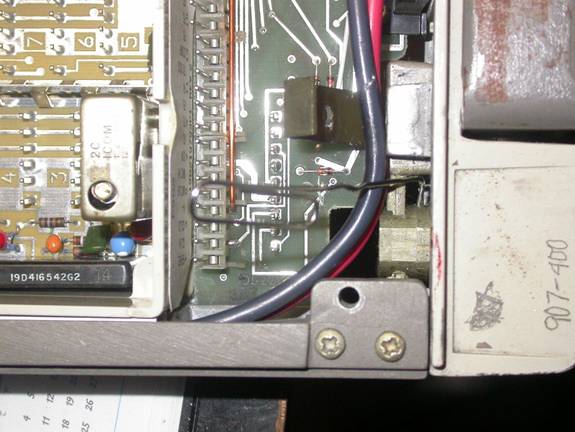

Now remove the top screw holding in the bracket

which retains the PA red & black power cables. You may have to unplug

the F1 channel element to get a good angle for the screw driver.

Now bend the bracket out of the way. This is

easier than tearing the radio apart to remove the second bottom screw

holding the bracket in. If you are not keen on bending, you can very

carefully back out the bottom screw. However it has clearance issues

with the system control board PCB. If you can loosen it some, the

bracket will swing out of the way. Itís up to you to bend or not bend.

Now insert the tool youíve just made into a tiny

hole on the side of the lock mechanism. Insert on the side shown. There

is another hole

on the opposite side, but it wonít work. Insert the

stock GE Key, but donít turn the cylinder.

Here is the tricky part. Apply pressure to the

tool, driving the end of the paperclip into the hole. Now slightly

wiggle/twist the GE Key around and with a pulling motion. Donít turn the

key very much in this process. Eventually the key and cylinder will pull

out of the lock. Donít get discouraged if it doesnít come right out.

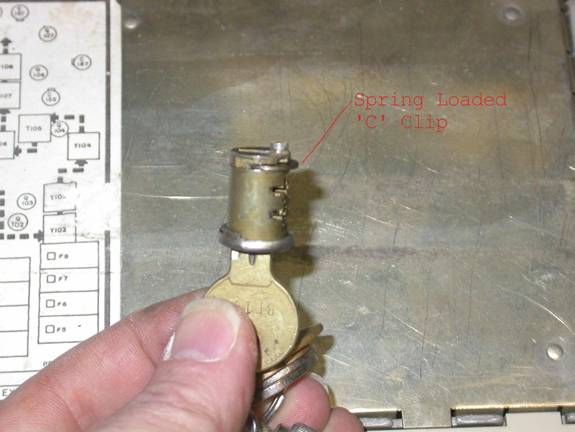

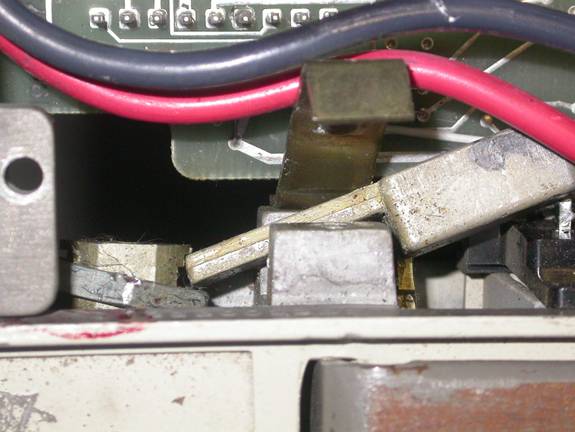

Youíll get the hang of it. What you are doing is depressing a spring

loaded ĎCí clip on the end of the cylinder. (See photo below). The ĎCí

clip is what is holding the cylinder in the lock mechanism. By dressing

it, it allows you to remove the cylinder. Note the position of the key

while it is being pulled out.

Here is a close up of the lock cylinder removed.

Note the ĎCí clip on the end of the cylinder. If you turn the key too

much during the removal process, the end of the paperclip wonít be on

top dead center of the ĎCí clip.

Now it is time to remove the remainder of the lock

mechanism. The lock is held in place by a large nut. Iíve used long

needle nose pliers before to loosen the nut. In stubborn cases, you have

to persuade it a little. Take a flat head screwdriver ( one you donít

like very much) and position it at the edge of the nut.

Tap the top of the screwdriver with a small hammer.

You are pushing against the corner of the nut at an angle. Usually one

good tap or two will free up the nut. At that point it will usually

unscrew easily by hand. Back the nut all the way off. Note: it canít be

removed because the slider bar is still in the back of the mechanism.

You can now pull whatís left of the lock mechanism

in the key lock hole forward to the front of the radio. This allows you

to angle the slider bar past the front control head connector J901 and

remove the slider bar. Pull out the remainder of the lock, lock washer

and nut.

These are all of the pieces that are removed from

the radio. I keep a cylinder around in the toolbox, just to remind

myself which way the key is positioned during the removal process.

Now bend back the retainer that was holding the PA

power cables and reinstall the screw you removed.

Congratulations, you now have an empty hole.

You can snake the controller cables through this

area. Alternatively, some folks like to install a second SO-239 for the

receiver in this hole. If you mount an RF connector here, this requires

you utilize the front control head connector to get at the signals for a

ham repeater controller. Youíll have to cut a factory control head cable

and wire on a mating controller connector. Iíve done it both ways in the

past. Personally, I donít like using the stock control head cable, as

itís bulky and heavy. This requires you use some sort of strain relief

for the cable at the ham controller.

The finished product: A backup UHF repeater in

case the main site hardware has troubles. As a finishing touch not shown

in the photo below, Iíll dress the cables using some of the black

plastic spiral wrap ( available at Walmart or an automotive store) to

dress the shielded audio/control cables from the keyhole to the repeater

controller connector. To the savy reader youíll notice an NHRC-4M2

installed. In this case, the cables coming out are for a remote base

radio.

A conversion where I utilized an RF connector in

the key-hole location. In this case the first Ĺ of a split site 6 meter

repeater.

73ís and good luck!

Ralph Hogan W4XE

[email protected]