Way back in 2008 I started thinking about how to improve the Heathkit SB-101 design to add extra modes and bands and to take more account of modern band conditions whilst retaining as much of the original architecture as possible. The main areas to address included dynamic range, spurious responses, WARC bands, Frequency and Amplitude Modulation, RF and IF selectivity, full CW break-in and RIT. Having already used the 7360 beam deflection mixer in an SB-310 rebuild I decided to use two of those as mixers in the receive path and two similar beam deflection valves in the transmit path to improve dynamic range and minimise spurious responses.

This is the third attempt at this project, the first two having failed at the design phase to find sufficient space for the additional electronics inside the existing SB-101 case. It has now been decided to make this a hybrid project with a partial solid state back end and a valved front end on both the receiver and transmitter.

The VFO will be a Vackar format with isolating buffer, SSB offsets and RIT. The frequency display will be a digital counter and LCD display.

This page will plot the (sometimes slow) progress of this project.

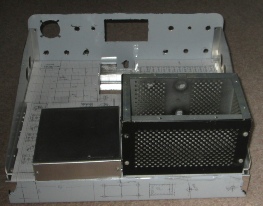

Step 2 - Having designed the overall circuit and drawn a 1:1 scale layout of all of the major components, a new chassis, side supports and front and rear panels were made. Photocopies of the layout were temporarily fixed in place on the chassis. The critical issue is to leave sufficient space to accommodate the new VFO enclosure aligned with the front panel decorative moulding.

The original PA compartment chassis was used as a drilling template for the major tuning components which are mostly in the same place as the original. Note that the 80m and 160m PA inductors are now wound on dust iron toroids, the 40-12m inductor has been redesigned and the PA bandswitch is now above the chassis.

Step 1 - plan the layout of the main components so that everything may be accommodated with sufficient space for cooling etc. More recently a five section wide band coupler has been completed resulting in a significant improvement in the stop-band characteristics and may be seen here.

The receiver and transmitter backends will be contained in one or more screened compartments on top and underneath the chassis to the left of the PA compartment (viewed from the rear), including the detectors, modulation sub-system, speech processor, FM sub-system, transverter interface and overall control logic. The original preselector tuning capacitor and respective inductors between the mixer, Tx driver and Rx RF stage have been replaced with screened pre-set band pass filters. The other preselector tuning capacitor and associated inductors (now in screened assemblies) have been retained. A solid state 150v regulator has been designed to power the VFO and other supply voltage sensitive circuits.

The initial part of version 3 of the overall layout is shown below to the right followed by the full layout.

Step 3 - The overall layout drawing is much larger than A4 so has been copied and printed in a number of separate sections as shown on the right. The print output was set to ‘no scaling’.

With all of the paper layouts fixed in place the chassis is now ready for drilling.

The blank area on the lower left of the chassis is for a screened enclosure below the chassis to contain the solid state circuits. The area above the chassis will contain a small sub-chassis, as shown.

The rear panel of the chassis will be drilled and punched in a separate process. The original Heathkit 11 way power connector has been replaced with a 12 way rectangular connector in order to accommodate the additional pins for the 12v DC supply.

The picture to the right shows the mostly drilled chassis, less the front panel, with some of the components and sub-assemblies resting in place (to check they fit!). The sub-chassis at the back right holds the CIO crystals; SSB, AM and CW generators and the ALC amplifier, freeing up space under the chassis for the additional solid state circuitry.

Concentric Controls

As the front panel will not easily accommodate all of the additional controls, a small number of the variable controls have been combined using concentric potentiometers. This required some re-engineering of the standard Heathkit control knob as can be seen to the right. The left hand example is a standard SB-Line one and the one on the right has had its fixed skirt replaced with a separate knob turned up from 1.125 inch diameter aluminium rod and lightly knurled.