The DMH Electronic Cutout Install

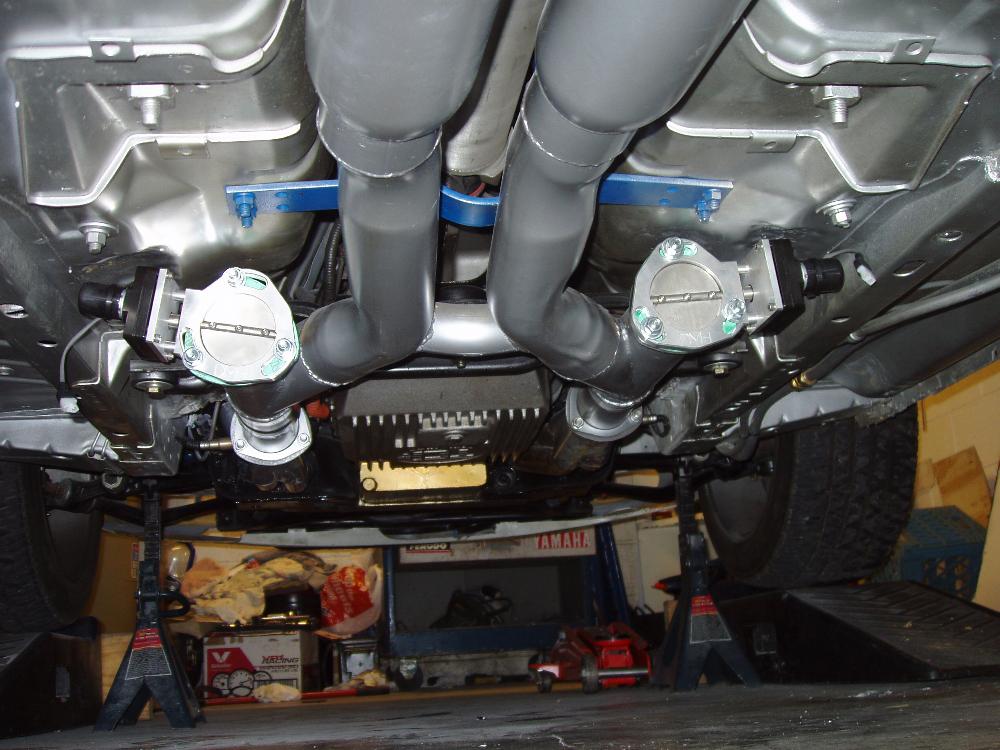

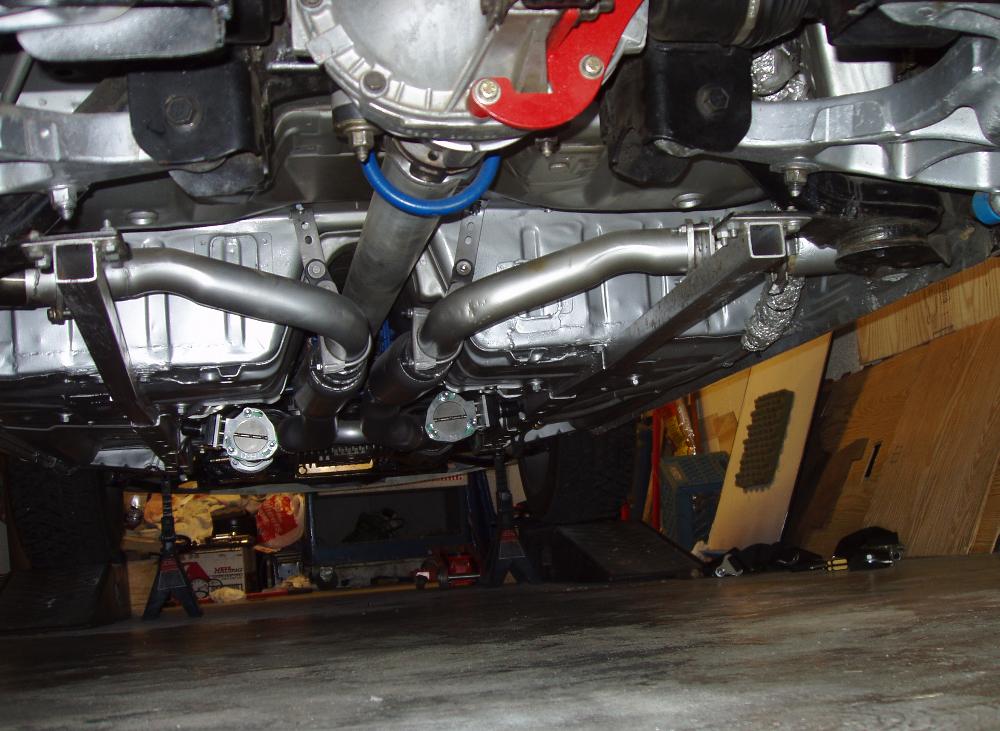

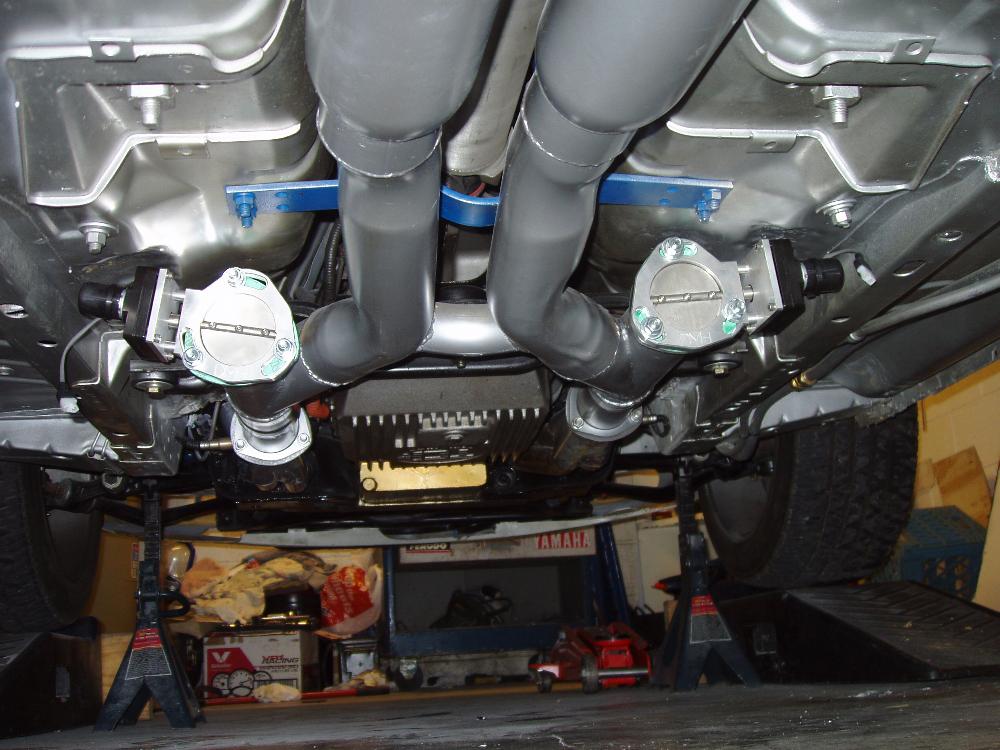

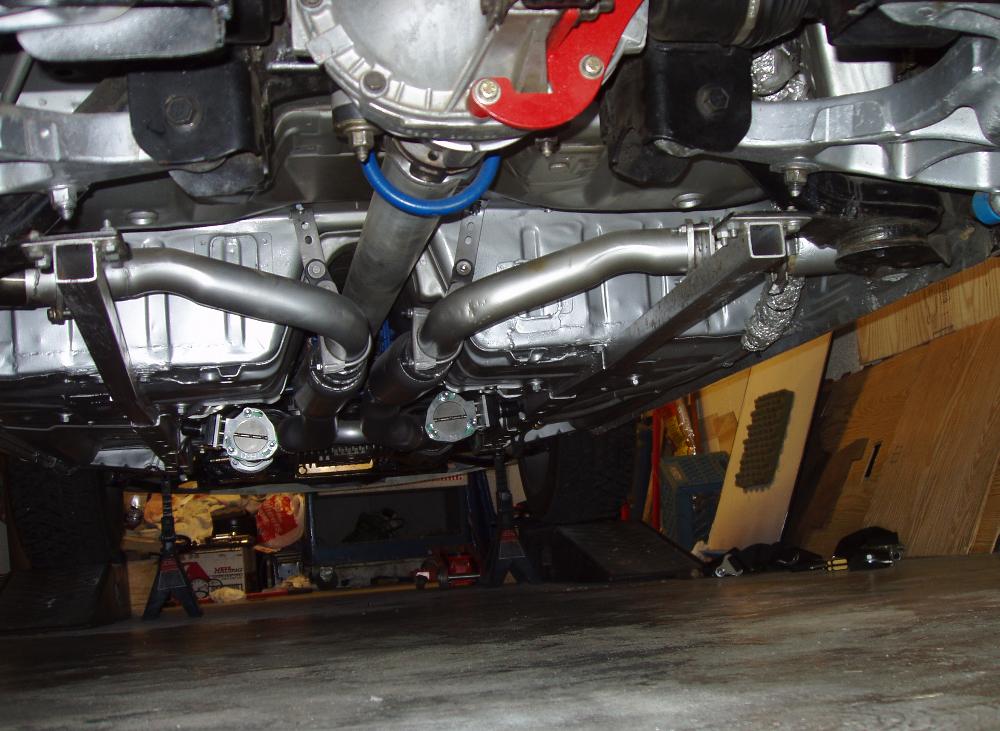

Modified turn downs added to direct the exhaust slight down, and to the sides at about 45 degrees. This will reduce the sound level slightly by directing it out from under the car, and not blow so much dirt around while driving it.

1. Weld your pipe with the 3 hole flange so 2 holes are on the bottom, so you have the maximum ground clearance.

2. Use a round or curved file to smooth the inside edge of the welded pipe so the cutout will not bind on any rough edges. The center opening part of the cutouts are very close to the inside diameter of the 3 inch pipe.

3. Use 2 gaskets between the cutout and the 3 hole flange to give a little extra room so carbon build up does not hinder the opening and closing.

4. For initial install, make sure to use the 3 black bolts and special nuts to position the cutout exactly center. The smaller part of the nuts go inside the recess of the cutouts to make sure they are centered. If you are going to use longer bolts for any reason, use these 1st, center it, test it, then replace them one at a time.

5. Mount the cutouts so the motors are tilted slightly upward, so and moisture will drain away from, rather than into them. Mount them so the motors are after the cutouts, not before. This will keep them away from the constant heat of every day driving.

6. Before installing them, bench test them. Mine were stuck, and needed tapped a few times with the handle on a hammer to free them up the first time.