How to convert your carburetor to E85

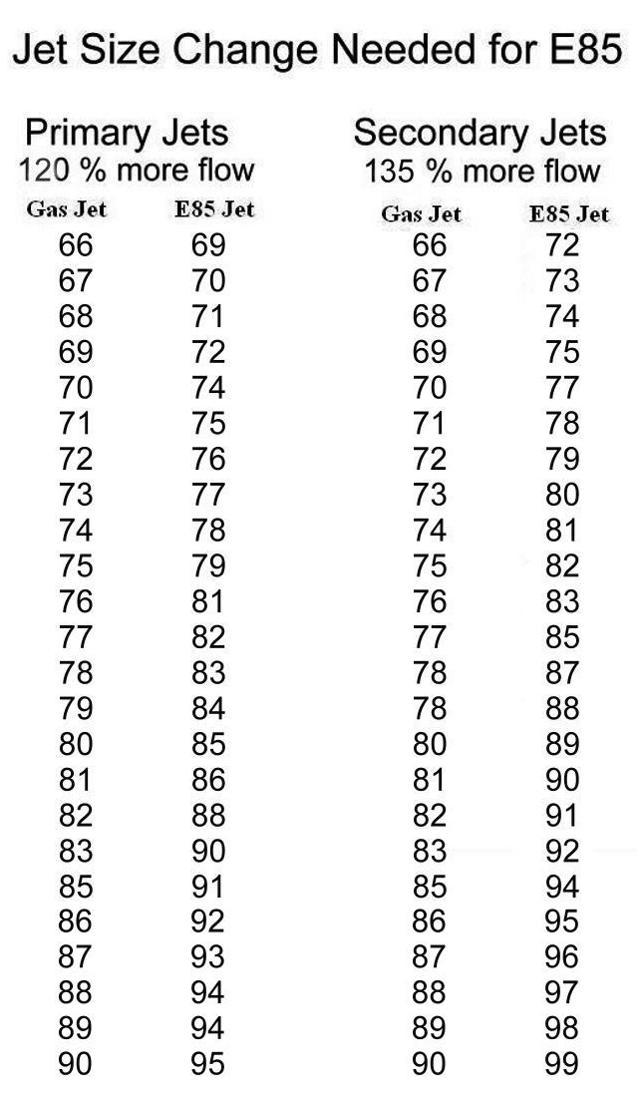

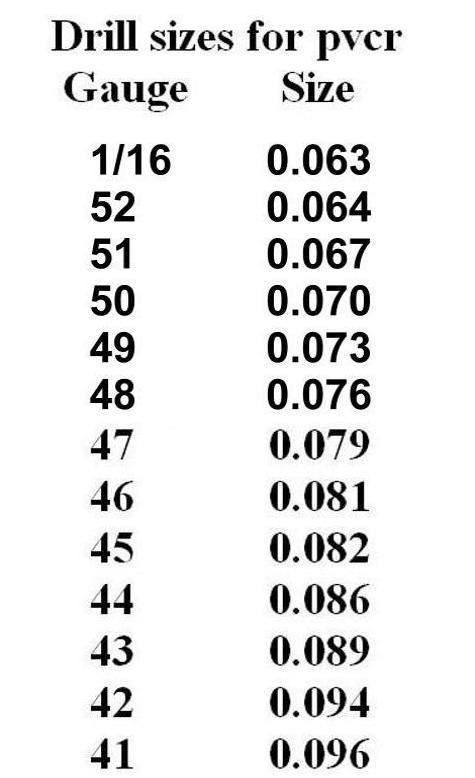

So if you have 75 primary jets and 85 in the secondary, you need to use about 79-84s in the front, and 92-96 jets in the rear. These are for a 750 carb, with the proper size PVCR passages in the metering blocks for the power valve. This is only a starting point, but very close.

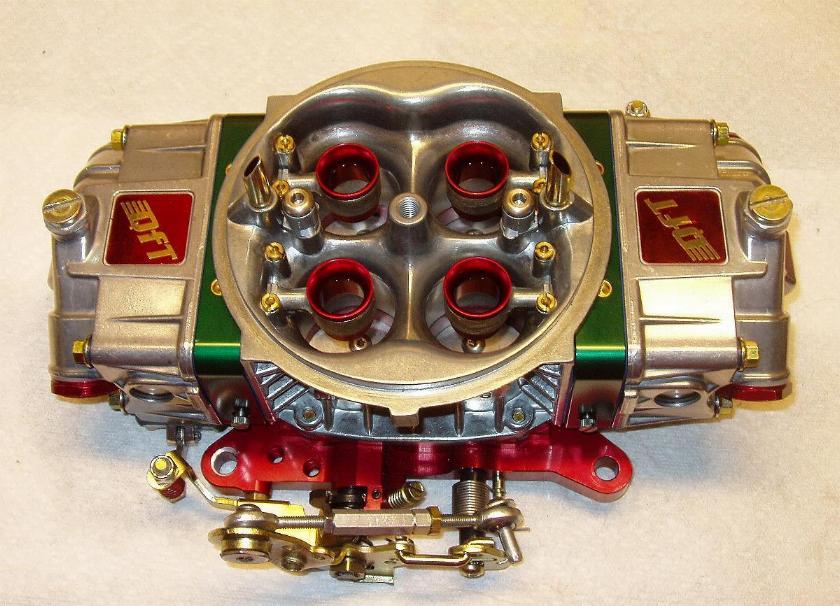

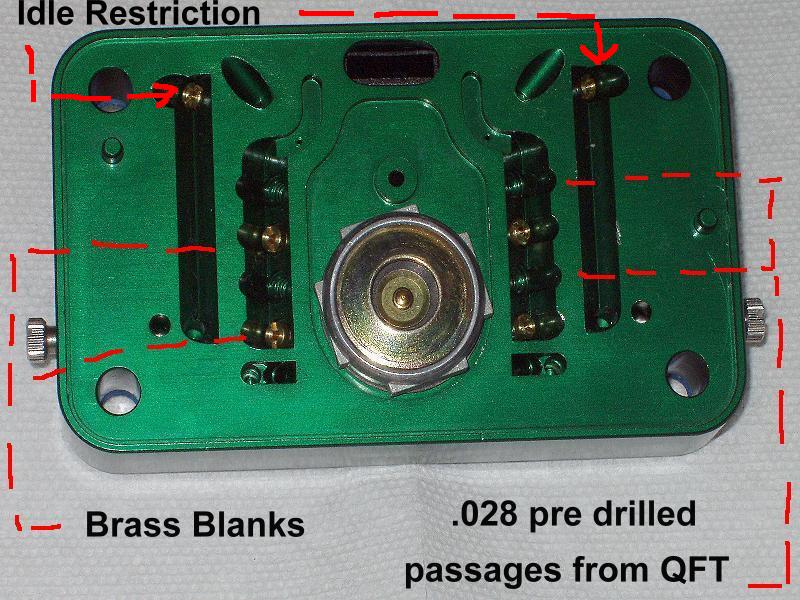

Here is a good starting point for a 750 DP Carb to E85. using

Quickfuel's E85 Metering Blocks, which have custom sized

internal passages to compensated for the increase in fuel

demand of E85. They are also hard anodized to prevent any

corrosion of the internal passages.

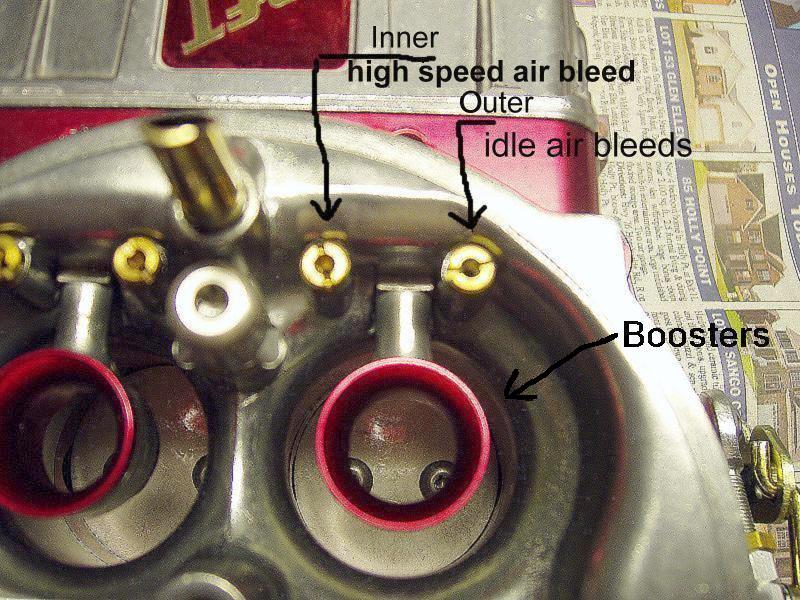

750cfm squirters = Pri .042 Sec .042 accel pump = 30cc Boosters = Primary 170, Secondary 180 IAB = .065 HSAB = .028 Idle Feed Restriction = .046 Emulsion holes = top down .028, blank, .028, blank PVCR = .094 (for boost) NA, about .076 Powervalve = 6.5, rear blocked Needle & seat = .130 SS fuel pressure = 6.5 psi Primary jets = .080 secondary jets = 96 (for boost) 92 (for na)

I add 1/2 oz of Stabil for each 5 gallons of E85 to help with any

problems caused by moisture, and give a little extra lube to the

fuel pump and upper cylinders. I added a ball valve to my fuel cell vent to seal

the system when it is parked. The Stabil keeps the fuel in the carb

from doing any thing funny if moisture gets in through the vents

while it is parked.

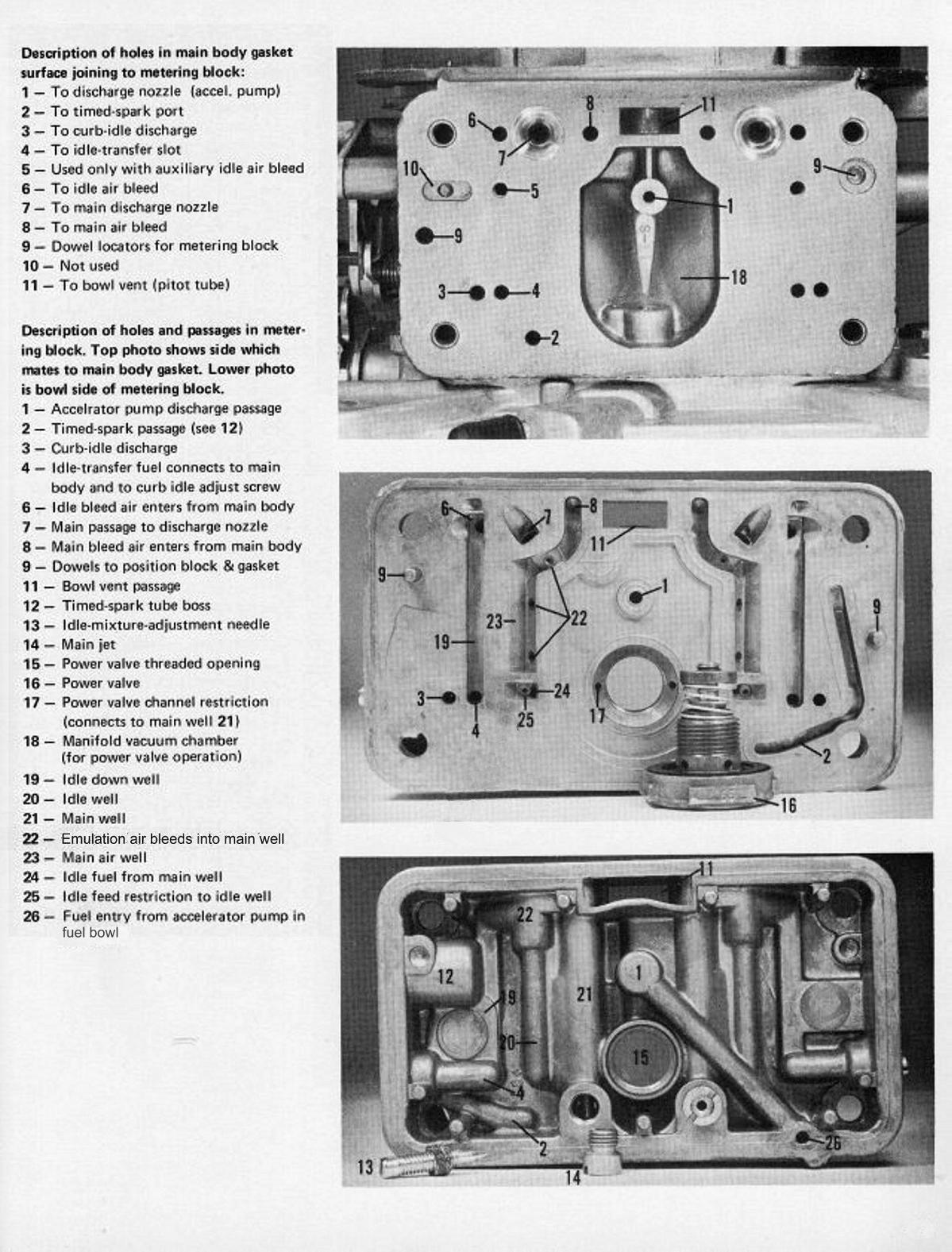

This shows the inner working of a typical

Holley type carb, and labels the passages.

With some time, you can set up the carb to have perfect

air fuel ratio from idle to WOT, and back to idle, and as

smooth as EFI. This is done by starting will a good

performance carburetor, then fine tuning it to your

application. If you get a custom built carb, they can build

the carb for your application, where all the work is

already done.

To remove the needle and seat, just loosen the screw as you would for

adjusting the float level, then turn the nut down some to force the needle up a little.

Slide the needle and seat out, then transfer the the nut and screw, along with the new

washers onto the needle and seat and install.

Turn the float bowl upside down to see where the float is set for.

This shows where to set the floats at after installing the new 130

SS Needle and seats You should also not be using brass floats,

as they will reach to E85 over time. Setting the float this way will get

it close. Make sure to check it while the fuel pump is on, and engine running

when installed. QFT has any parts you need.

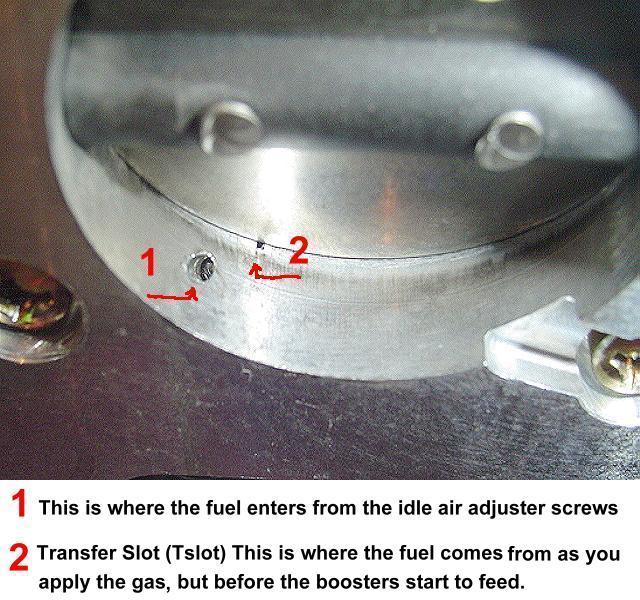

The Tslot should be exposed slightly as shown. Not having any showing will cause a stumble as you apply the gas from it going lean. Having too much exposed will feed enough fuel to the engine at idle, to make adjusting the idle air fuel screws not have any effect, making it idle too rich. It is best to set the Tslot so the opening that is exposed is as long as it is wide, square. After doing this, make your idle speed adjustment using the secondary idle adjustment screw. If you are running a real radical cam, this may not be enough to control the idle. If that is the case, drilling small holes in the throttle blades may be required to provide enough air to the engine, while the blades are nearly closed. On some older carbs you may have to remove the secondary adjuster screw from the bottom of the base plate and put it in from the top to allow easy access. The Tslot controls the fuel delivery until between 2200 and 2800 rpms in most engines when the fuel starts feeding from the boosters. If you are rich or lean before that, it is most likely from a idle air adjustment, Tslot, or emulsion circuit that feeds the Tslot causing the problem.

TIP: The best way to test your carb, is to do the primary first by its self.

This will prevent the flow of the secondaries from masking any lean spots that

may be in the primary from too small of jets, or incorrect sizing of the PVCR

passage. Disconnect the link on the linkage to the secondaries until you have

the primary fuel curve correct. Having a Wide Band O2 meter installed before

you start would be a great asset. You can use it, along with checking the spark

plugs, to get a good safe fuel curve, that will perform great at the strip, and

cruise with only a slight increase in consumption.

Quickfuel

has all the parts needed to convert your carb, and also will

build you one that is set up for your engine for

Normally Aspirated, or for E85 Blow Through.