|

A Jumpered Dipole Antenna

My original plan for a portable HF antenna for the

trailer was to do something different and build a jumpered dipole.

Then I decided I didn't have time nor the energy to make one before

Field Day 2009 and bought a G5RV Jr instead. Upon reading the

instructions that came with the G5RV Jr, however, I found that any

metal near the wire feed line would detune the antenna. It further

specifically stated not to use it with a metal antenna pole, which I

would have on the trailer. Yes, I could make do with it by taking

additional PVC pipes for masting, but why go to all that trouble? It

was time to go back to "Plan A".

A jumpered dipole offers low loss (assuming negligible

resistance across the jumpers), coax feed, and in most conditions an

uncompromised bandwidth and a standard dipole pattern without a

tuner. The major disadvantage is that you need to lower the antenna

each time you switch bands. This can be difficult at night. It may

not a good choice for rapid or frequent band changes, but for a

portable antenna used as an Inverted "V" for Field Day, it

should work fine. I already had the set-up built for lowering the

center of the "V" from the mast.

I like the idea of having a full half-wave dipole for

the 40, 20 and 10 meter bands, and with the MFJ-949E antenna tuner I

use for portable operation, the antenna will also work on 30, 17, 15,

and 12 meters for occasional DXing if/when the HF bands improve. The

antenna I chose to build was patterned after one shown in the

November 1996 QST magazine. I found the plan to be very close to what

I had envisioned when I contemplated building the jumpered dipole earlier.

Materials List:

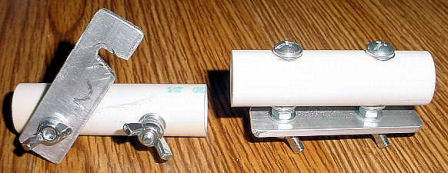

Making the insulator/jumper assembly

Before laying out wire for the antenna, I made the

insulator/jumper assemblies. There are several was to make a jumper,

and most will be lighter in weight than what I made. I even thought

of using Anderson Power Pole connectors on wires. They certainly

would be light weight, but possibly difficult to connect in the dark.

The original plan called for pieces of flat Plexiglass

for insulators. I didn't have any on hand, but I did have 1/2"

inside diameter PVC water pipe. Four 3" pieces were cut from it

and drilled for #8 bolts.

After pushing the bolts through the PVC pipe and

fastening them with nuts, I marked the aluminum for drilling. After

drilling the two holes for the bolts, I used a drill, hacksaw and

file for finishing the notches.

No flat washer was used on the outside of the

notched end between the jumper bar and wing nut. The #8 washers are

so thin that it would take a lot of time to fiddle with getting the

metal bar between them when lengthening the antenna. It  would

be almost impossible in the dark. This way, all that needs to be

done is the turn the jumper assembly until the bolts are upright, and

the single washer on the inner side of the metal bar drops into place

against the regular nut. would

be almost impossible in the dark. This way, all that needs to be

done is the turn the jumper assembly until the bolts are upright, and

the single washer on the inner side of the metal bar drops into place

against the regular nut.

To change to a lower band, let down the antenna,

loosen the wing nut on the unnotched end slightly, loosen the wing

nut on the notched end of the metal bar, turn the assembly so the

bolts are pointed upward, flip the notched bar onto the bolt, and

tighten both wing nuts. It's easy, even in the dark. Make the same

adjustment to the other half of the antenna, and then raise the

antenna back into position. To go higher in frequency,

"unlock" the appropriate notched end on each leg of the antenna.

Your first reaction might be, "Wow! I would have

to lower both sides of the dipole to change bands." You would be

correct. That's why I have chosen to use the antenna in the Inverted

"V" configuration.

I checked to see what the length of each antenna leg

(connector included) should be, then started out with additional wire

on each leg. It is easier to cut wire off then to add it. An MFJ-249B

antenna analyzer was used to determine the length of each individual

dipole section, starting with the band highest in frequency and

moving outward to the lower bands.

If you are unsure what frequency

to cut the antenna for on a given band, cut it to cover the SSB

portion you intend to work. You can always dangle a short piece of

wire off the end of the section in use to bring the antenna to

resonance on the lower frequencies. If you want to expend the extra

effort, you could make complete additional sections of wire for the

lower frequencies to substitute when necessary. I'm not that much of

a purist.

We did not have time to test the

antenna with a rig, however the antenna analyzer showed full band

coverage on 10 meters at 2:1 SWR across the entire band; coverage of

the entire 20 meter band using 14.180 for the center frequency and

both band edges at 2:1 SWR; and all but 8 KHz of the 40 meter band

with band edges showing an SWR at 2:1.

Used with the tuner, the antenna

performed very well on 40 and 20 meters during the 2009 Field Day

event in June.

Things I would do differently next

time? I am not a fan of 14 gauge stranded wire. It is too flexible

and tangles easily. I would use solid wire, or at least 12 AWG

stranded wire. I would also use a flat base for the insulator/jumpers

rather than PVC pipe. It is difficult to keep the bolts tight on a

rounded surface. Using 2" rather than 1-1/2" bolts with the

PVC pipe insulators would provide more usable threads when changing

the jumpers.

(Continued on next page) |

![]()