|

The motor and fin structure ready to be assembled into the lower section. The 4" PML body tube has been fiberglassed and primed with the fin slots cut at this point. |

| Detailed view of the 3/32" G-10 fin mounting details showing 1/4" hardwood dowels used for reinforcement. Also visble is one of the blind nuts used for engine retaining screws. |  |

|

The top of the lower section showing the parachute canister and vent holes for the ejection gases. The larger vent hole allows an ejection cannon mounted underneath the camera payload to extend down into the lower section. This arrangement allows for "zipper-less" parachute deployment while the canister provides complete protection for the parachute from the hot ejection gases. This has proven to be a very effective alternative to wadding or piston systems. |

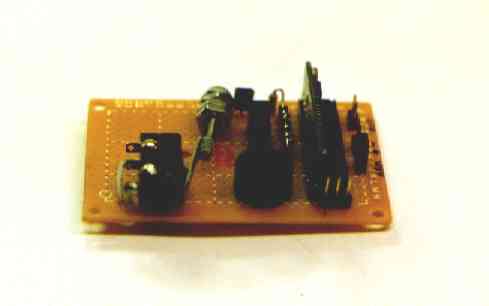

| The homebrew ejection timer used for backing up the altimeter ejection system. Visible is the weighted microswitch which is used to detect launch acceleration and the "Basic Stamp" microcontroller containing the timing software. This unit is settable by DIP jumpers for delay times from 1 to 31 seconds in 1 second increments. |  |

|

The nearly complete rocket waiting to be painted! The upper section shown here is for first flight testing. The camera payload section with it's chute canister is still under construction. |