If It Ain't Broke, Don't Fix It!

Observe the scorch marks on the top right of the case directly above the amplifier tubes. This HA-14 has been "run hot and put away wet". Chances are these finals were overworked and undercooled and may be soft. Proper cooling would probably have avoided this damage.

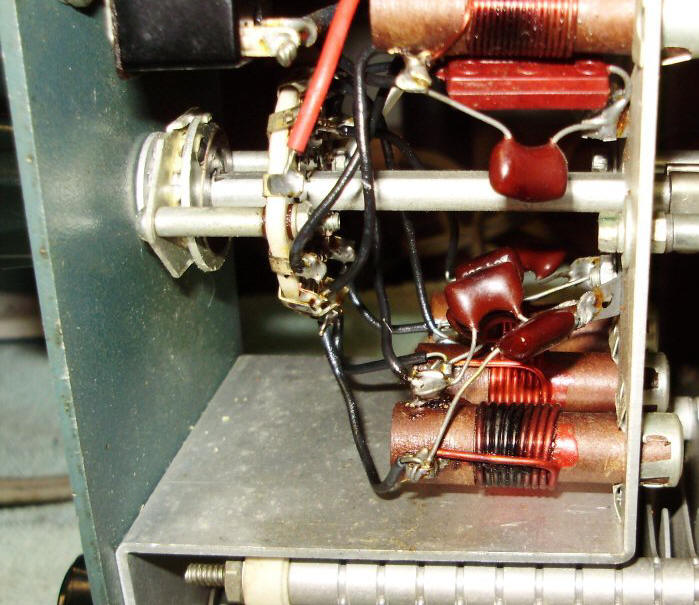

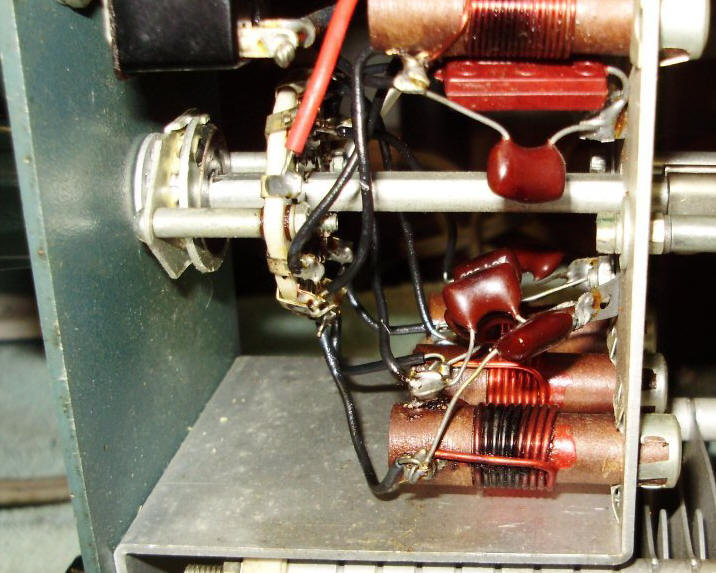

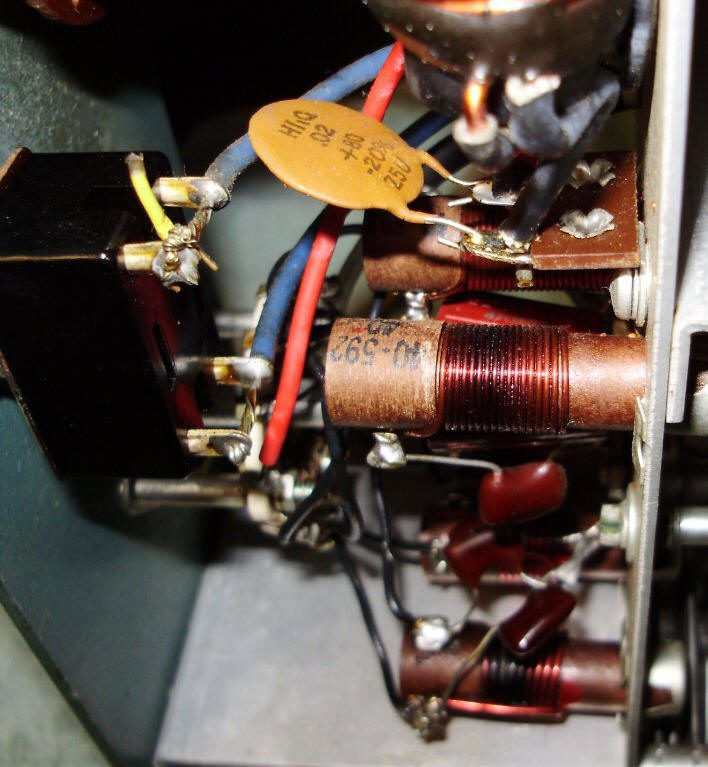

This is what happens to the tuned input coils when the HA-14 or any other amplifier is overdriven. Here we see the 20M coil scorched and inoperative, and some others appear singed. This could have been caused by too much driver power. Or, maybe feeding the amplifier without the high voltage. Could a very high SWR over a period of time have caused this?

What do you think caused this failure? Pse send your ideas along...

(Photos courtesy WA4JWU)

Here is a case of "If it ain't broke don't fix it." The RF INPUT jack does not need replacement with a UHF jack. The ceramic insulated phono jack supplied works just fine. The only potential improvement could be to use a higher quality phono plug with a sturdy handle instead of the standard minimal plug which was furnished.

An all too common butchery of the HA-14 is to cut out some of the solid strips on both sides of the HV connector to make bigger holes to improve the air flow. Small fans may then be added to cover the holes. But look how close the plate caps and +2500 vdc are to the edge!

IMHO there is no real benefit to be had by chopping on any of the HA-14 family. Used as intended the system works well.

This HA-14 interior looks nice and clean. There is no obvious salt air corrosion. The soldering appears at least marginally acceptable but should be carefully checked. No components appear stressed due to short leads and there are no obvious modifications.