| Homepage / | W2WDX Station Info / | Modes / | Other Links |

| New Additions / | QSL Info / | Amateur Articles |

Barker & Williamson 5100B Transmitter

History & Modifications

The B&W 5100B was manufactured between 1955 and 1961 by the

Barker & Williamson Company of Bristol, PA (near Philadelphia). This

transmitter offered both AM radiotelephony and CW radiotelegraphy on the

80, 40, 20, 15, 11, and 10 Meter Amateur Bands. The unit had a self

contained power supply. The 5100B is rated at 180 Watts DC power input to

the final amplifier on CW, and 140 Watts on AM, typically putting out

nearly 100w carrier. The transmitter is well known for its audio quality,

its modular design (more on that later), and its heft tipping the scales

at 85 pounds.

A separate phasing type sideband adapter was also made for this

transmitter, the 51SB-B. It is housed in a matching chassis, and the 5100B

has threaded mounting holes and cable feed-thru holes in its right side

for attaching the 51SB-B. The adapter is connected via octal type, Cinch

Jones, and several terminal strip connections. It is fully powered by the

5100B, as well as using the 5100B PA stage.

For AM operation the 5100B has a basic plate modulation

topology of a pair of 6146's in push-pull AB2 as a modulator, plate

modulating a pair of 6146's in a Class-C PA. The audio/modulator circuit

consists of a 6U8A for the mic preamp (triode section) and second stage

(pentode section), and a 6AQ5A audio driver which is coupled to the 6146

modulator tubes via a 4:1 interstage transformer. The outputs of the

modulator tubes are fed into a modulation transformer which is directly

coupled to the plates of the PA. With the exception of a Centralab

couplate which resides between the second audio stage and the driver

stage, the 5100B has none of the clampers, limiters or other audio

limiting gimmicks found in many transmitters of the

day.

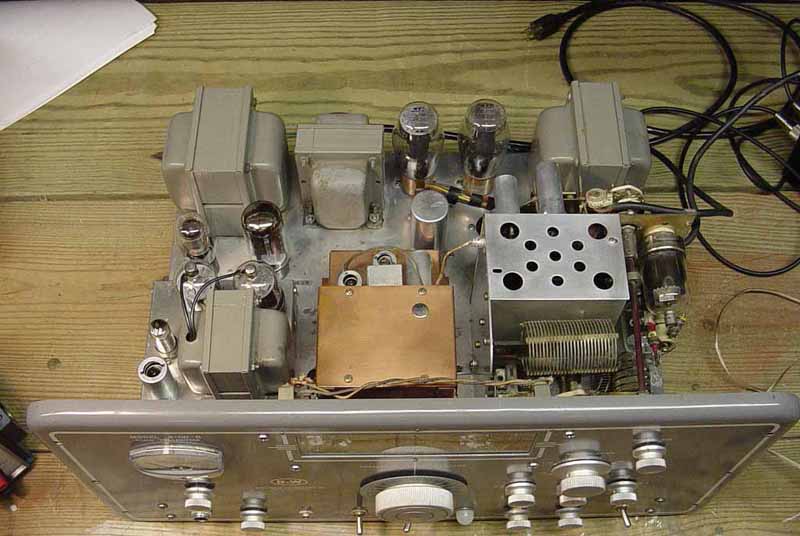

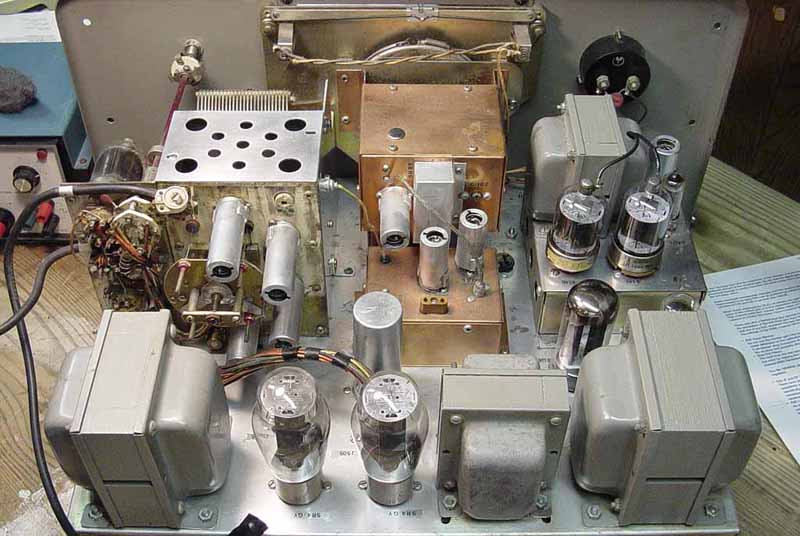

One of the nice features of this design is the modular

construction of this transmitter. The modulator, VFO, crystal buffer unit,

and the entire multiplier/RF PA unit are removable as separate complete

entities. They are connected to the chassis via various octal type and

Cinch-Jones connectors which are connected through holes in the the

chassis. Once removed, the only thing remaining on the chassis is the

power supply components and the internal wiring. The VFO comes out

complete with the housing for the circuits and the complete mechanical

tuning knob and dial mechanisms attached. Most of these modules are

removed simply by taking out just four screws on each unit, a few more for

the VFO unit. The VFO and the Mult./PA also only require you remove the

the knobs. The shafts just pull out the front panel. No fiddling or

removing the front panel nor are there any sub-panels here. The shafts are

not attached to it. They have there own mechanical support built into the

respective module itself. For instance, if you make the proper cabling, it

allows you to remove the modulator, plug in the cable and work on the

modulator on the table in front of your transmitter and test the circuits

while it is connected and running attached to the transmitter in

situ.

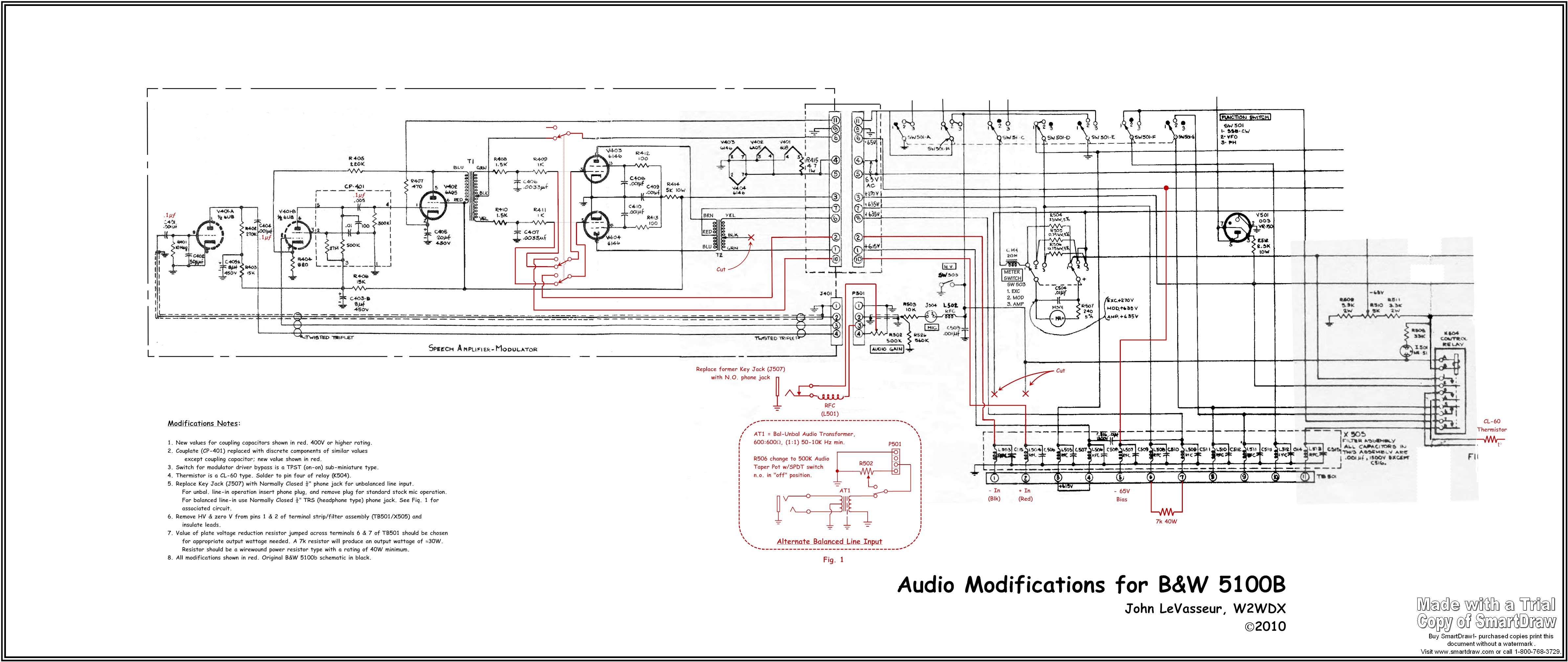

This article details some modifications that can be performed

to improve the overall audio quality. Near broadcast quality audio

can be had after these mods are performed. There is a PDF document with a

schematic documenting all of the mods mentioned here. This schematic is

not a complete schematic of the entire transmitter and only includes the

circuits within the scope of this article. However the circuits are shown

contiguous, and not just chopped up into isolated segments.

Here's a link to this schematic:

http://www.qsl.net/w2wdx/images/Mods.pdf

A high

resolution JPG of this is available here (huge file warning!):

http://www.qsl.net/w2wdx/images/Mods.jpg

A full

schematic & users manual for the B&W 5100B can be found at the

BAMA site. Here's a link to that document:

http://bama.edebris.com/download/b&w/5100b/5100b.djvu

You

will need a program (DJView) to view the manual file. Download it at: http://windjview.sourceforge.net/

Some Simple Audio Mods

Changing the values of the coupling capacitors in the audio chain

to .1µƒ, replacing the stock .001µƒ caps, is enough to fatten up the audio

quality significantly. Also replacing the couplate with discrete

components and changing the coupling cap to .1µƒ as well is highly

recommended.

Another slick trick involves some more involved modification. This

one does sacrifice the Key input in favor of using it for a line level

input. It involves simply disconnecting the RF choke following the key

jack input, replacing the Audio Gain pot with a similar value pot that has

a SPST switch attached to the back. The wire that came from the mic amp

stage to the pot is placed on one side of this switch and the other side

of this switch is wired to the end of the pot where this was previously.

The RF choke coming off the former key jack is then wired to the wiper of

the pot. In this configuration all you have to do is turn the audio gain

to zero or in this case "OFF", and the switch disconnects the mic preamp

from the rest of the circuit. Plug in your line level audio chain and

adjust the audio level using your outboard audio gear, preferably

monitoring on a scope. If you want to simplify this you can simply replace

the Key jack with a ¼" phone jack that has a normally closed contact and

keep the stock gain pot. The contact disconnects the internal mic preamp

when a plug is inserted. Remove the plug for stock microphone operation.

(Note: This is the mod shown on the mod. schematic).

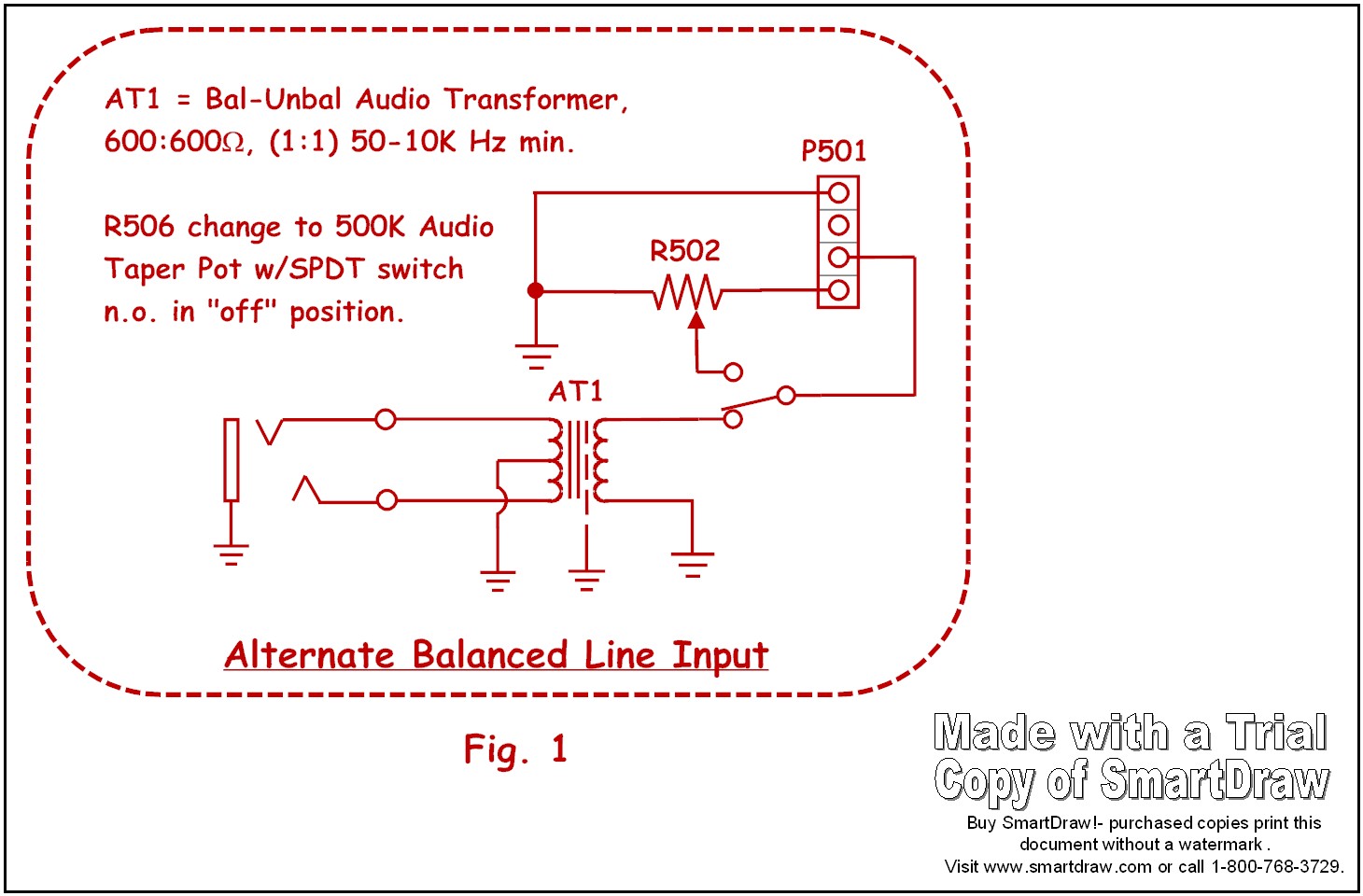

If you want to

take this a step further, you can change the phone jack to one that is TRS

(tip-ring-sleeve). Wire in a small 1:1 600O audio transformer that

converts balanced to unbalanced. Wire the ungrounded side of the

unbalanced output of the transformer to the pot switch contact and the RF

choke (which leads to the wiper of the pot) to the other side. Wire the

common to pin 3 of P501. See Fig.1 (The pot switch in this case must be a

SPDT type). This allows you to drive the radio with a balanced line level

signal when you turn the gain knob to the full "off" position. In the "on"

position this switches the input to the internal radio audio driver chain

with the pot controlling level from the stock mic input as usual.

One note: While Radio Shack offers a 1:1 transformer of this type,

its frequency response is quite limited and may defeat the purposes of

these particular mods, that being broadening the audio frequency response

of this modulator. There are much better transformers, which are very tiny

in size offered on the web. Jensen makes several (what I used was a Jensen

JT-11SSP-6M), but these can be pricey for the more frugal HAM's. The

Jensen I used is sever overkill but I had one from my audio profession I

wasn't using, so I used it here. Many small high quality transformers

which are much less expensive are available. Check online.

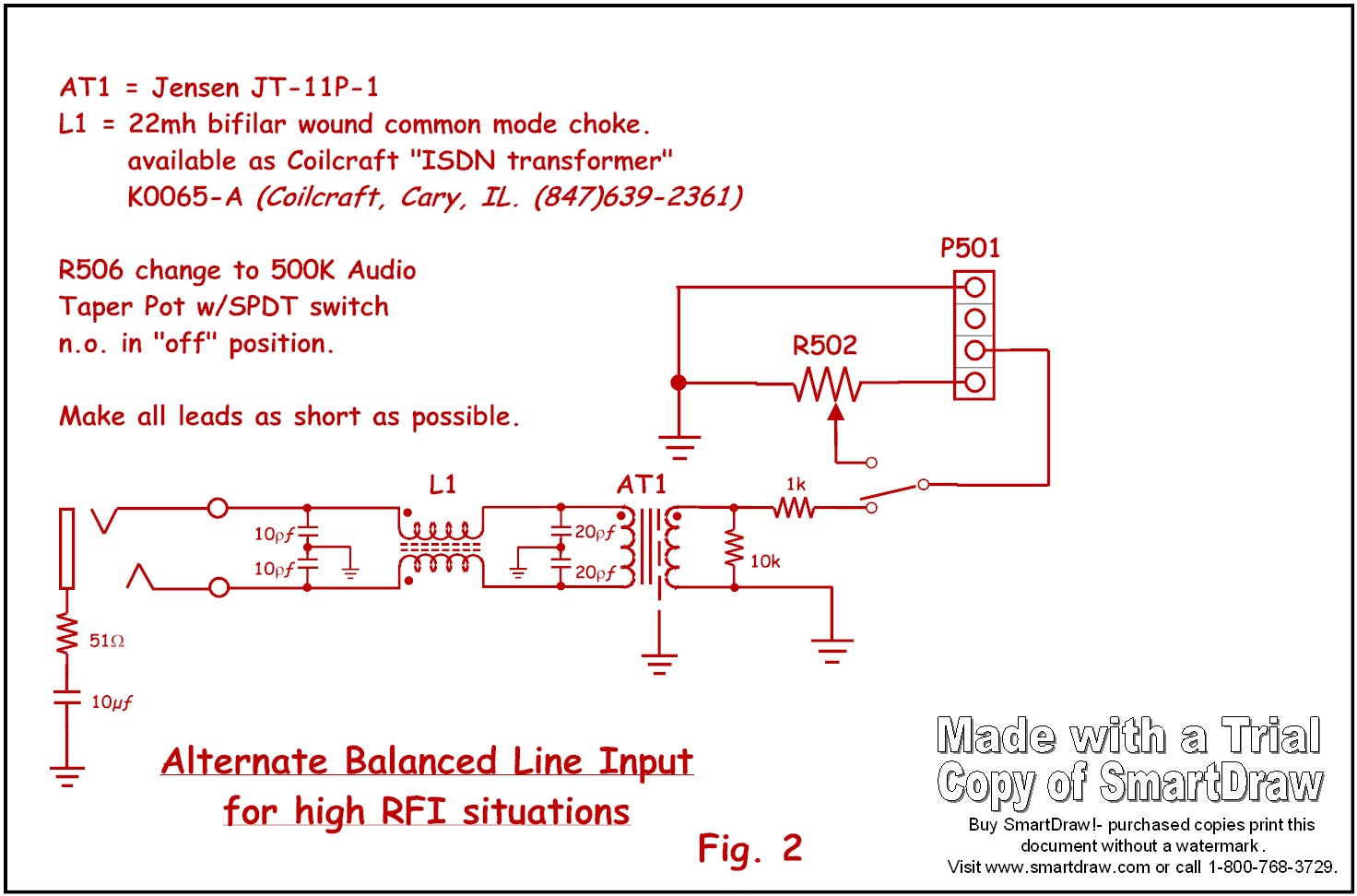

If you

have an RFI problem or just want to prevent the potential of one, you

could try this circuit. (See Fig 2) This circuit also has some additional

changes that might better match the input of the 6U8 which could be

incorporated into the original alternate circuit. Values may change if

other transformer are used other than the Jensen & Coilcraft

types.

These mods allow you have the original microphone input (for

your beloved D104) with the gain control and have a line level

input without changing the appearance or function of the radio one iota!

(except for the front Key input).

Modulator

Modifications

Some more sophisticated

modifications of the modulator can be performed that can improve overall

sound quality of the transmitted signal. Some of these that I have

performed involve very minor drilling and installation of items like

internal switches & connectors.

The suggestion was made to me

one evening on the air by Jeff, W2NBC to connect an external drive stage

directly to the grids of the 6146 modulator tubes. (Hmmm) This is the

classic audio amplifier connected to a flipped around hi-fi audio output

transformer to drive the grids. The method I used was specific to the

audio gear I had available and other methods and gear can certainly be

applied here. I had an old Dynaco ST-70 tube audio amplifier. One of the

nice features of this old vintage amplifier is the use of very high

fidelity output transformers. Also, the amplifier would have more than

enough power output to drive the grids of the 6146's and maintain a high

level of headroom in the driving audio amplifier. This amplifier uses two

EL-34's in P-P.

I disassembled the ST-70 and removed one of the

output transformers. Basically, I removed the entire "left" channel and

all of its components, leaving it as a "monoblock". After cleaning up the

chassis, repainting the transformers, and otherwise making it all nice and

pretty, I rewired the amplifier and set the bias. I checked the amplifier

for performance.

I took the removed output transformer and mounted

it on one of those Hammond cast-aluminum project boxes, added two pair of

five-way binding posts and a ceramic feedthru connector for the bias

voltage for the 6146's. I wired the 8O secondary to one set of binding

posts and the primary to the other binding posts next to the feedthru

connector. Across the binding posts connected to the 8O secondary I

soldered an 8O/50w resistor. For the mod that follows, any low power audio

amplifier can be used. Output power of the amplifier should be between 8

to 25W. Any hi-fi P-P type audio output transformer can be used, flipped

around and loaded with an 8O power resistor.

Now comes the mods to

the 5100B that involve the drilling. (Don't fret ... it's just one tiny

hole on the modulator sub-chassis). On the modulator module between the

modulator tubes and near the edge of the chassis, drill an appropriate

hole and mount a sub-miniature TPST switch. This switch disconnects all of

the radio's circuitry before the grids of the 6146's and connects the

grids and the bias voltage directly to several unused pins on the 11 pin

plug (P401) that connects the modulator to the radio chassis

circuitry.

In the modulator, on P401 remove the black wire on pin 2. This

is a terciary output lead from the mod transformer that is not used for

normal operation of the transmitter (except when used with the 51SB-B SSB

Adapter ... I think, not sure). Insulate it well and leave it. Remove the

ground connection from pin 10. (Don't worrry, there is already another

ground connection on pin 9 and this connector can handle the current with

just one ground pin. Besides the chassis is at the same potential, and

these pins only come into play when you have the modulator module removed

from the chassis). The lead connecting the grid switch of V403 goes to pin

2. The lead connecting the grid switch of V404 goes to pin 10. These are

used to connect the switch which controls the grid input switching to the

terminal board on the rear of the chassis.

On the main chassis,

several terminals on the terminal board (TB501 Term. 1,2 & 5) are

utilized to feed the signals from the external source to the modulator

grids via its large multipin plug on the bottom of the modulator

sub-chassis. To do this remove the HV wire from terminal 1 and the zero

volt wire from terminal 2 and insulate them well and just leave them. Then

move the wire from terminal 5 and move it to terminal 1. Also locate

the -65v negative bias voltage and wire that to terminal five. You may

want to take it from the J503 connector or the wiper of R510 (Mod Bias

Adjustment) mounted on the chassis near the PA section. Disconnect

the ground lead from pin 10 of the 11 pin jack (J503) and run a wire to

TB501 terminal 2. The wire you moved from terminal 5 to terminal 1 on

TB501, connects the other switched grid lead.

Now connect the

positive lead of the flipped output transformer to terminal 2 and negative

to terminal 1 and connect the center tap of the transformer (the ceramic

feedthru connector) to terminal 5 on TB501 for the bias. Fire up the

transmitter and run up your audio amplifier. Using a scope, monitor your

transmitted output waveform for 100% modulation.

Refer to the

schematic provided here to clarify the connections.

The Simple "Turbo"

Mod

While the pair of 6146's in the PA can

produce a 90-100W carrier output on this transmitter, you may want

punch that up by using an external linear amplifier. Unfortunately,

most commercially built amplifiers will be toast quite quickly if you

drive it with that carrier level. Not to mention you will have no headroom

left on top of the modulation peaks, if you have any.

To reduce the

carrier output on this transmitter, a very simple and effective "mod" can

be performed. Simply remove the jumper connecting terminals 6 & 7 on

TB501. This an external access point for the plate voltage which goes to

the modulation transformer. I should point out here, the voltage across

these terminals is 635V and can really smart (or even kill) if you are not

careful. Across these terminals place a power resistor between 7k &

20k (depending on the amount of output you need to drive your amplifier).

I used the type that has the screw terminals on it and mounted just above

the terminal strip on the back of the chassis on the perforated grill. I

used two ceramic standoffs to mount the resistor, and uses high voltage

wire down to the terminals. The resistor should be rated at 40W minimum.

No change to screen voltages or any other modifications seems to be

necessary, as far as I have observed.

That's all there is to it.

Works well!

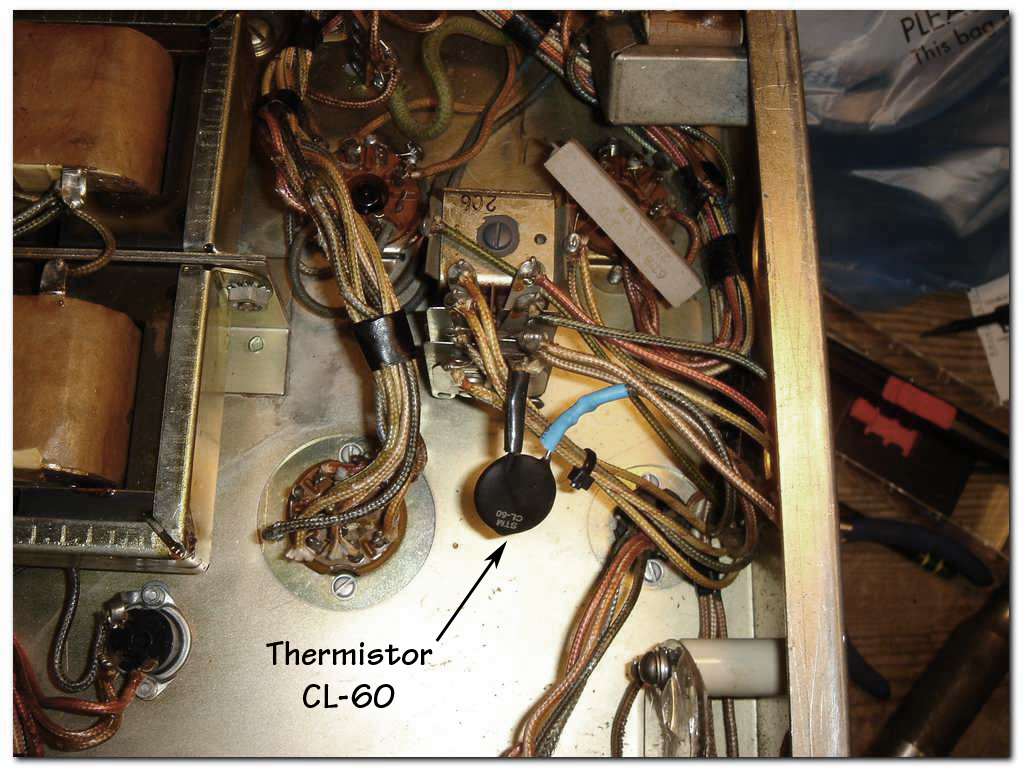

The Simple Soft-Start

A

nice mod that limits the inrush current when turning on the B+ (and to get

rid of those loud "ka-chunks" that could at times shake the entire cabinet

of the 5100B) is adding a thermistor in series with pin 4 on the Control

Relay (X504). A CL-60 type thermistor is a good choice. The time constants

and current rating is perfect for this transmitter. It is rated at 5 amps

steady state current, 10 ohms cold resistance and about 0.2 ohms when hot.

These get very hot, so take care where mounting it!

This mod came

from Mark Bell, K3MSB.

Replacing the Selenium

Rectifier

There is a selenium rectifier (SR501)

used on the negative bias voltage supply. These are prone to failure and

should be replaced. Remove the selenium rectifier from the ceramic

standoff it is mounted on. Screw a terminal strip with multiple lugs onto

this standoff. Watching the polarity, use a 1N4007 diode to replace the

selenium. In order to match the voltage drop of the selenium rectifier,

place a resistor in series after the 1N4007 to achieve the correct

voltage. You should do this by trial and error until you achieve the

correct voltage of -140V on the negative side of the 40µƒ/150V filter

capacitor (C519) that follows the diode.

Some Things to Check When When You Get Your

5100B

Since this transmitter is now over 50 years

old, you should of course change all the electrolytic capacitors. Most are

contained on/in the main chassis, and two more are found in the modulator

module. Use high quality NEW (not NOS) capacitors. The FP can type

electrolytic (C520), which is a 40/40/40µƒ @450V, is still available if

you want to "keep it original". CE Electronics is still manufacturing this

can new, using Mallory's original equipment. But they are not cheap,

costing around $34USD at retail pricing. It can be purchased online from

Antique Electronic Supply (www.tubesandmore.com). I only suggest them since they

usually have this can in stock all the time (as of the time of this

writing). Of course you can simply use ordinary axial lead caps underneath

to save money. Whatever type you choose, do this first.

I stayed

with the stock values of capacitance. On the bias supply I recommend

raising the voltage rating from 150V up to 450V on these capacitors, since

the first filter cap in that supply is very close to the normal operating

voltage of -140V. I have found the amount of capacitance in the stock

design is more than sufficient, and the stock supply is fairly stiff as

is. No hum or ripple was detected anywhere in the circuitry. The oil

capacitors in this transmitter (one used across the HV choke & two

feed-thru filter caps on the AC input), most likely do not have to

replaced. But it is advisable to check them for leakage, as a rule of

thumb.

One other suggestion I would like to make, is on the

resistors (R520 & R521) used across the HV filter capacitors. While

the original design uses 68K, 2W, 10% carbon composition resistors,

I went with hand matched 2W, 5% Metal Oxide Power Resistors instead. Even

distribution across these capacitors allows the filtering to work better,

so the closer tolerance coupled with the better long-term reliability of

these types of resistors seemed like a good choice. It is a minor thing

and not important or even necessary, its is just small detail I felt could

be addressed.

While you're in there, you should also check the

values on the various carbon composition resistors. They do change value

over time and should be checked. Replace any you find out of

value.

The 5100B uses two continuous bead chains to drive the

mechanical of the multiplier. These can stretch over time, causing the

chains to slip. There is an "idler" wheel on each that can be adjusted to

take up slack. Do not make the adjustment too tight. And whatever you do,

don't break those bead chains! They are the rarest & most difficult to

find components in this transmitter. They are made from pure unobtainium!

If the multiplier tuning control works smoothly, it's best not to mess

with these chains.

If you find you cannot reach 100% modulation you

should check the 4.7O/1W filament dropping resistor (R415) for the 6U8

(V401) inside the modulator. Its value can and does change over time in

this transmitter and it will reduce the modulators ability to achieve full

modulation.

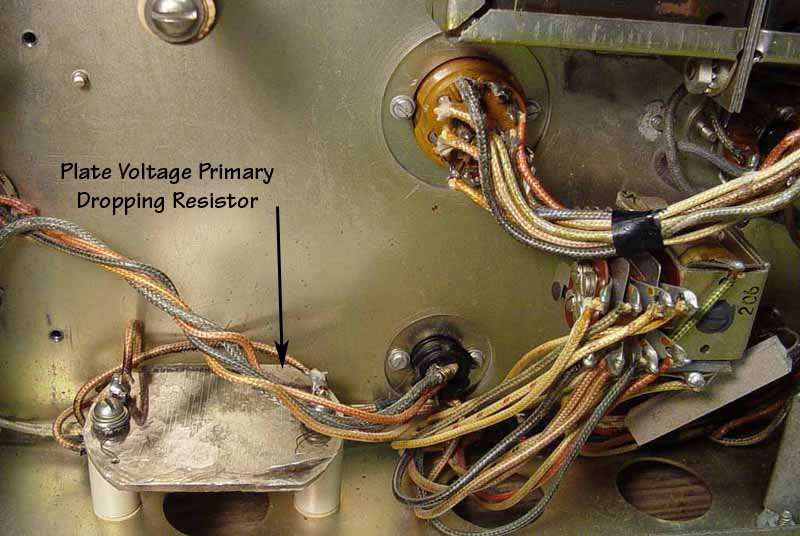

You may get a scare the first time you tune your "new"

5100B when smoke appears near the modulator the first time you switch it

into tune mode. Inside is a very unique plate voltage primary dropping

resistor (R525 "Special Resistor"). It is comprised of a disc of mica

wrapped with about 20 turns of Nichrome wire, which is then sandwiched

between two more discs of mica. It is mounted to two ceramic standoffs.

Sometimes if the transmitter hasn't been used for a while dust and stuff

may build up inside or on this resistor and burn off when the transmitter

is first tuned. If you find this resistor is not functioning, it cannot be

found. It has to be made. I bought sheets of mica & nichrome wire, and

using an x-acto knife and alot of patience, made a new one that functions

and looks exactly like the original. I used the original as a guide for

cutting the mica sheets. I made two, just to have spare. If I can do it, I

assure you it can be done by anyone. Since it's not mentioned in the

schematic or manual, the value of the resistor is 27O at probably about

50W. Any power resistors near these values can be used, of course. The

circuit seems to draw about 30-35W while used.

... And In Conclusion

The

B&W 5100B is a great transmitter; a true classic! Hopefully some of

these modifications will allow you to enjoy it more without having to tear

it apart. The performance will be increased and it will remain virtually

original.

73

John LeVasseur, W2WDX

[email protected]

P.S. - I

would like to thank Mark S. Bell, K3MSB for his assistance and knowledge

of this transmitter, and his subsequent contribution to this paper. (www.k3msb.com). The

images used here are of his 5100B and as soon as I get a working digital

camera I will put up images showing my mods in detail.

Also, I am

sure that there are some technical flaws in my modifications, due to my

limited experience at the time of this writing. While they may work fine

for me, I of course may be unaware of a better approach. That being said,

any suggestions for improvements and/or corrections are encouraged and

appreciated!

| Homepage / | W2WDX Station Info / | Modes / | Other Links |

| New Additions / | QSL Info / | Amateur Articles |