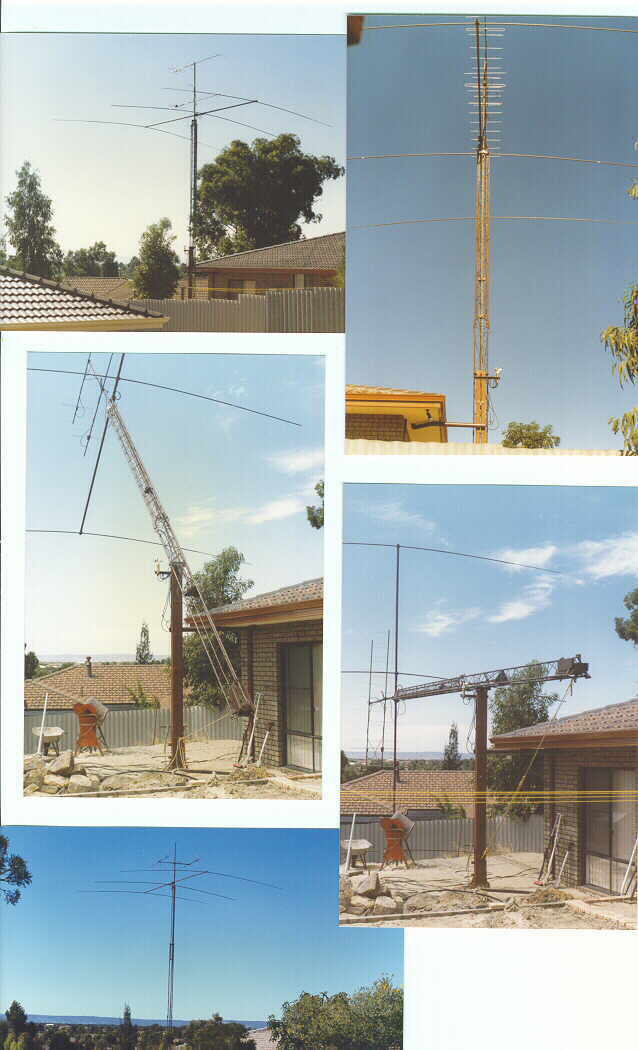

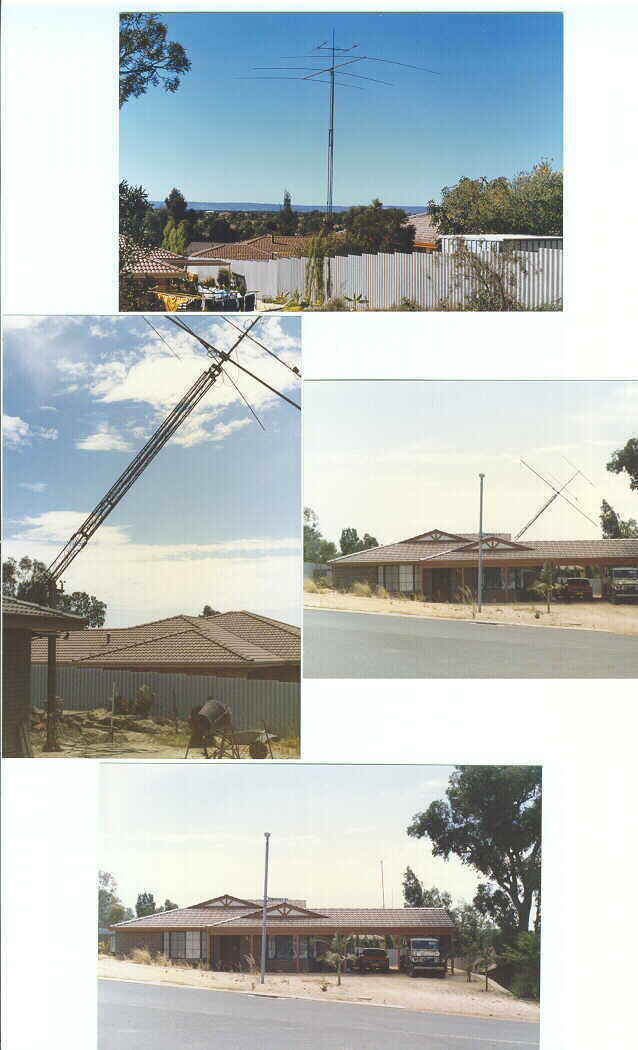

| I hear all the new Hams saying how they can't put a tower up in a residential area...... I say where there is a will there is a way.... and I don't take NO as the final answer to anything. In business this has stood me well over the years and in putting up a tower it is the only attitude. Anything can be done it's just some things are harder than others and as a good friend always says "How Bad do You Really Want It". In many cases that is really the question as some would rather quit than compromise, by compromise I don't mean an antenna in the roof. After buying a block in 1986 in a NEW area and it was just as bad then, the covenants said you could not even have a TV antenna on the roof unless it was painted the same colour as the roof. Before I built I checked 2 of what I saw as important issues surveyed the height above all surrounding houses for the footings, the tower that is, and the house for the views. That's what I told the XYL anyway and of course line of site with the TV transmitters must have good TV reception that ensures less chance of interference problems. Now the next challenge, the Shire I was told was the worst in the state - nothing like a challenge. No point being shy just went in and asked for the EXACT by-laws governing the erection of a 15m radio mast on the lot. After a short discussion I was presented with the rules, and here is where you start. You need to get them to put in writing exactly what they require so you know what you are up against. Well I needed the signed permission of 12 of the nearest neighbours they selected, this took a documented presentation to each and every person over a 12 month period. I presented draft plans to the shire and here came the punch line. They required it could be folded down when not in use......... with tongue in cheek I said is that all, fine I will come up with a design. Fold a 15m tower down, Holy Cow that was a tall order.... but if that was the only challenge then get on with it. After a lot of research I found the design for a commercial tilt over, in a way I was lucky as all the engineering specifications were on the plans. So down to the local engineer to recalculate the structure for wind loading with a 20m beam and footings for local soil conditions and sign it off. Bingo the shire approved it......... Now for construction phase..... The base is 3 x 44 gallon drums sunk vertically in the ground with a round pilon of galvanised steel 250mm in diameter all back filled with concrete with a 380mm diameter by 40mm plate welded to the top with 12 x 25mm bolts attaching to an identical plate on the top. All had to finish flush with the ground, a great deal of care was taken with the tower footing position and the house pad placement so I could swing a full size 27ft/8.23m boom 4element 20M Yagi on top when finished. Next came the above ground pilon this was made of 2 x 90mm steel box tubes strapped and welded together then welded with gussets to the flange plate. All this welding was done in the back yard of my folks place in the middle of summer 40 degrees celcius over many weekends laying many large fillets of high tensile welds (don't attempt this unless you are qualified, I had done welding during my trade and Dad was a coded welder for the railways, an old air cooler blowing cool air through the welder so I could run it continuous for 8 hours at a time ) so good advise was well at hand. Now modify the original tower to telescope, hold thrust bearings at centre, rotors in bottom section, and add the hinge point and some extra bracing as required. Then off to the hot dip galvanisers to galvanise everything... Back to site (in the middle of all this I have just moved into a new house we have no drive way yet and I am laying slate on the floors inside at night) anyway now the next shire requirement you guessed it I had to paint it to match the roof. I know you got to be joking no they wanted it brown so it is brown. Finally it is erection day the footing has been down for 2 months and I have used the electric winch on the 4wd to hoist the pilon up and tensioned all 12 x 25 mm bolts and this is not going any where...... a gin pole and a lot of winching and inching with crow bars and we slide the hinge pin in just on dark. By now the neighbours have taken sympathy on me after all the work and the next door neighbour even gets involved and helps, he cut a large solid steel counter weight at his work from solid steel weighs about 80kg that is bolted into the bottom of the tower to offset the tower weight above the pivot point. Was it all worth it, YOU BETTER BELIEVE IT! So if you have the will there is a way, but I will not say it was easy by any means, nor was it cheap and I already owned the tower sections. Below is the construction Photos I was not kidding when I said the house was being built at the same time.... A recent addition above the Rotator, a 100 mm Drum Brake for high winds this stops the Yagi smashing the gears in the 75 km/hr plus easterly winds we have in the summer months. This has been very effective and just uses a hand brake cable and lever to actuate. |