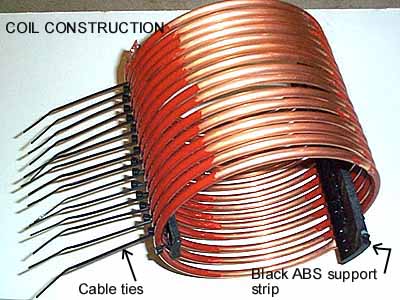

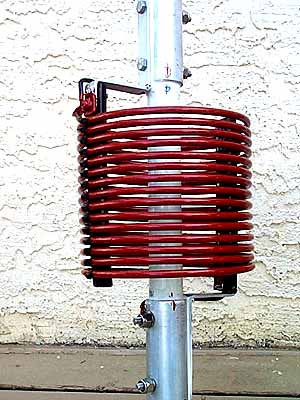

1 1/4" solid fiberglass rod is used for the element split insulator. The split is 8 " long. The coil is 15.5 turns of 1/4" copper tubing, 6.2" dia. and 6" long. Mouse over the photo at right to see the end view. |

COIL DESIGN-ELECTRICAL Using a DOS program from Brian Beezley K6STI, it was possible to design some low loss loading coils. Working with the program it became clear that not only conductor size and coil dimensions were important, but form loss plays a significant role in determining Q. The final loading coil design was 15.5 turns, 6.2" diameter, 6" long using ¼" copper tubing. Using an AIR core this coil shows a Q of over 1300 with a loss of only .5 ohms (3.8 MHz). This same coil design using a PVC form has a Q of only 250 with 3.5 ohms of loss. (See screen shots below) The program provides a choice of 15 different form materials. The final physical coil design at VE6WZ is "mostly air core" and will probably show and sustain a Q of around 500 to 1000 (loss .7 to 1.5 ohms). This is likely better, or at least comparable to the small gauge linear loading wire approach. (See here for some good info. on loading coil design by Tom W8JI ) |

|