Appliance Timer

Yes I know you can buy an appliance timer at the

store for 10 bucks or so but as usual I have my problems with those.

For one thing, they use batteries inside that run down at inconvenient

times. For another the user interface is arcane and I have trouble

programming them. The clocks are not accurate, and must be reset often. Finally they are so cheap the buttons and switches don't

work properly and fail after a while.

I use a timer to turn a lamp

on at night and off in the morning. This is simple enough, but where I

live, daylight hours vary substantially throughout the year. The timer

must be reprogrammed every couple of weeks. Now if I designed my own timer,

I could create a program with a table of on/off times for each week of

the year. You can't buy that feature at the store.

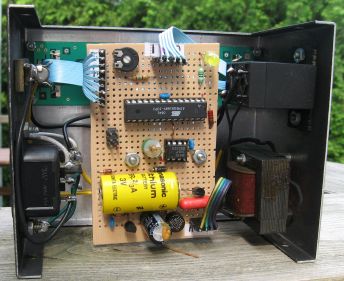

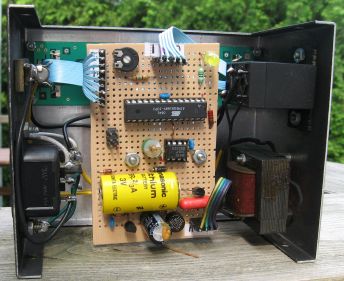

I had acquired a few KTM-S1201 LCD displays, which are 12

numeric 7-segment digits. I wanted to use one in this project, but some

alphabetic prompts were necessary. I wrote a module to do this, using

the best fit upper/lower case letters for the 7 segments. The result is

not pretty, but works.

The only control is

a rotary encoder/pushbutton. Once set up, the unit displays the time in

24 hour format. Turning the knob either way turns the attached appliance on and

off. Pushing the button puts you in setup mode, where a menu is

displayed and managed by twisting the knob and pushing the button. You

can set the on time, off time, set the clock, and so on.

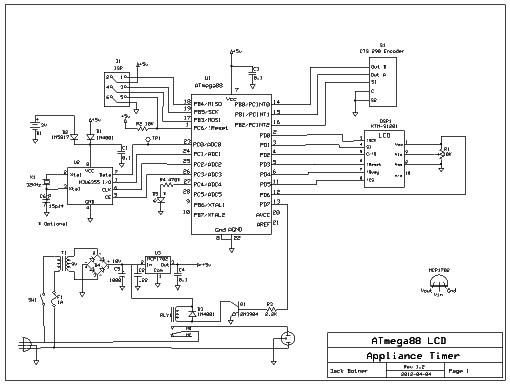

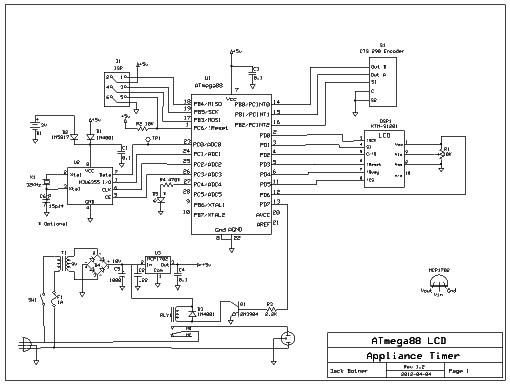

The

battery is a 3 volt lithium cell which I had on hand. It runs the clock

when the unit is unplugged. You can use one of those small 3 volt coin

cell batteries if you prefer. The 5 volt regulator I used is a

MCP1702-5002E/TO (Digikey P/N MCP1702-5002E/TO-ND) however a 7805

should work just as well.

The rotary encoder is a CTS series 290 rotary encoder. More information on this part can be found on my rotary encoder page.

I

found relay RL1 in my parts bin. The coil is 12VDC, but works fine with

my 10 Volt supply, switched through Q1. The contacts must be able to

handle the load's current and voltage (a small fluorescent lamp in my case).

There are two operating modes, Run and Setup. When powered up the display shows the time

in HH MM DD (24 hour) format and the unit is in Run mode. If you twist the knob,

the appliance switches on and off, as a manual override. If you push

the button, the program goes into Setup mode and displays the

1st menu item. Twisting the knob moves up and down on the menu.

Pressing the button selects the menu item for further processing. The

menu items are:

� Run - pressing the button returns you to run mode.

� Timer

On/Off - This option turns the timer function on or off. The menu item

shows what the changed state will be, so when the timer is on, it will

say Timer Off.

� Set Clock - You must do

this once to set the RTC. With each push of the button you can set

year. month, day, hour and minute. After the final button push the time is set

with zero seconds.

� Set On Time - to set the timer ON time, hours and minutes.

� Set Off Time - to set the timer OFF time, hours and minutes.

� Prepgm

On/Off -works similar to Timer On/Off. Selects whether you want to use

the On and Off times entered above (Prepgm Off), or the table of on/off times coded

into the program (Prepgm On).

� Clk Test - This

puts the NJU6355 into its "Frequency Checking test mode" where it

outputs its clock signal on the DATA pin. This is very handy for

adjusting the frequency to exactly 128 kHz using the trimmer capacitor

C6. There is more information here. There is no return from this mode except to power cycle the unit.

The

decimal shown at the right hand side of the display in the photo

indicates that the timer is on. When the preprogram is also active, two

decimals are shown.

Look for the preprogram tables in function set_current_programmed_on_off_times(), module appltimer.c.

There are four tables, ucOntimeHH, ucOntimeMM, ucOfftimeHH, and

ucOfftimeMM. Each table contains 52 entries, one for each week of the

year. Unless you live in Toronto, Ontario, the times in the tables are

not suitable for you and must be changed. I used the US Naval Observatory data services

to generate a chart of sunrise and sunset times for an entire year for

my location. I then used each 7th entry in the chart for my on and off

times table, with a small adjustment. I wanted the timer to turn on 10

to 15 minutes before sunset, and off 10 to 15 minutes after sunrise.

Keep in mind that the times change a bit in the course of a week,

and cloudy days appear to have less daylight than clear days. All

the times are in Standard Time; elsewhere the program checks

for Daylight Time and adjusts the hour as required. The program is

coded for Eastern Time; for other time zones a few more tweaks are

required in the code. You will then have to rebuild the project.

I used AVR Studio and WinAVR GCC,

both freely available. Create a project with my .c and .h files. Select

ATMega88 (or ATMega168) as the processor, and a clock frequency of 8

mHz, and build.

The

program stores important state variables in EEPROM, so that if powered

off for any reason, it will come back on in the same state. The RTC

remembers the date and time, as long as the battery is good, which

should be a few years.

Update

Nov. 1, 2012 - When setting the clock you set the date as well as the

time, so the RTC knows the date. (However there is no normal display of

the date.) I use the date to calculate when Daylight Savings Time (DST)

kickes in and out, in order to adjust the preprogram table

times so the relay turns on at the expected time. Later I realized

I could use that information to automatically adjust the clock so it

did not have to be done manually twice a year. It is hard coded for

Eastern Time, North America. If you implement this project elsewhere,

look at the code in the calendar.c routine and make the necessary

adjustments. DST is a big Pain in the Ass and in my opinion serves no

useful purpose except to confuse and inconvenience people, and

certainly makes this project needlessly complicated.

Download C

source code for the timer

Back

to VE3LNY's AVR Project Page