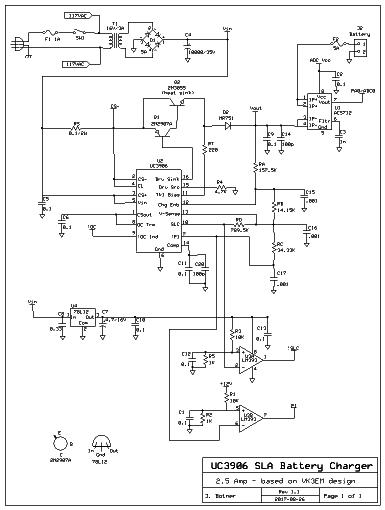

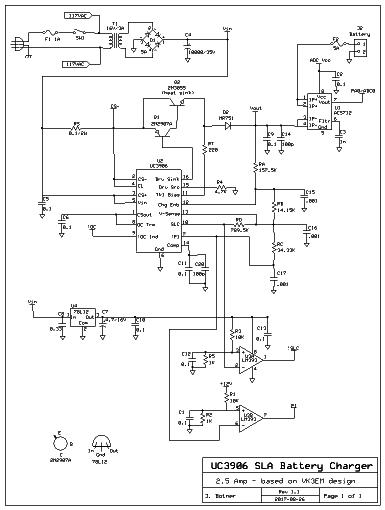

UC3906 SLA Battery Charger 2.5Amp

This project is a follow-on to my original SLA

charger project.

If you're not familiar with it, please have a look for the background

information. The UC3906 datasheet can be found here,

and the UC3906 application note here,

and VK3EM's project here.

(If the UC3906 links are broken, do a web search on UC3906.)

2020-08

Update: As interesting and useful as this project has been, there are

commercial products available today that are neater and cheaper than

projects like this. For example, the NOCO Genius series. I'm not throwing my chargers away but I probably wouldn't build another.

My 55 AH Gel-Cell battery finally packed it in

after more than

10 years. I credit its long life to my UC3906 charger. I

replaced the battery with a larger 100 AH deep-discharge marine SLA

battery. I wanted a charger with more oomph since the previous one was

only 1 Amp. This one is good for 2.5 Amps. It is based on the same

UC3906 charger chip, with a beefier power supply and pass transistor.

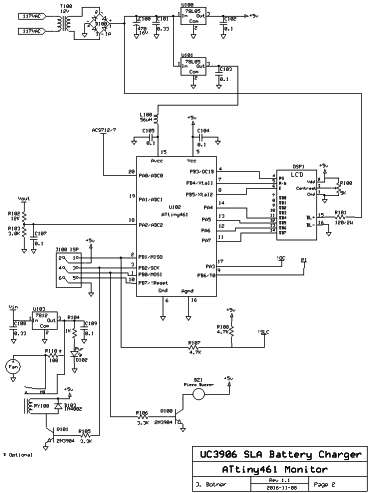

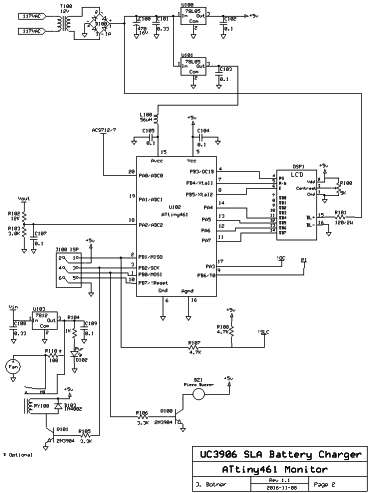

In addition, I added an ATtiny461A to monitor the state of the

charger.

(Click to enlarge the schematics.)

I didn't really understand how VK3EM's monitoring

circuits

worked until I developed this project. The UC3906 doesn't specifically

provide

status information except for SLC (State Level Control, or float charge

mode) and Overcharge Indicate (OC), and even that

is not very useful. The UC3906 operates in three modes: bulk

charge, overcharge, and float charge. OC is sometimes

on for bulk mode, then on for

overcharge mode, then goes off. I wanted to display on

the LCD which state the charger was in. Having watched the charger

during a complete cycle, I have come to the following conclusion: In

bulk charge mode, OC may be on and SLC (state

level control) is off, and the current is at Imax. (Here I use logical

state, not actual state, since both indicators are

inverse

logic.) The charger goes into overcharge mode when the battery voltage

reaches 90% Voc. If OC was off it comes on. What happens is the

charge current starts to drop, maintaining the battery near Voc for a

period of time. After a while OC goes off and

SLC goes

on, and the charger enters float mode and maintains the battery at the

float charge voltage

Vf.

So

to know what state the charger is in you also need to know the charge

current. If OC is on, it may be in bulk or overcharge mode. If the

current is at or near Imax, it is in bulk charge mode. When the current

drops off, it is in overcharge mode. When SLC goes on (and OC off), the

battery is in float charge mode. You might also be able to distinguish

between bulk and overcharge mode by watching the battery voltage, if

you know what Voc is, but current is more useful.

VK3EM's project provides for an

LED to indicate float charge mode by monitoring SLC, which is fine as

long as everything is working right. I don't

agree with VK3EM's comment about the elevated charge

(overcharge) indicator circuit, that the OC pin changes state from bulk

to overcharge mode. I did not observe this consistently (although it

would have

been nice if it had). Interestingly his Elevated Charge circuit is 'not

fitted',

possibly because it didn't work as planned.

VK3EM's charge

current monitor circuit is of dubious value, as he documents in his

paper. Measuring tiny voltages across a small value resistor sitting at

the supply voltage rail is very difficult and even harder to interface

to a microprocessor. I decided to try a

different approach, to use a Hall-Effect current sensor from Sparkfun

Electronics,

p/n BOB-08882*.

This contains a ACS712

5 Amp Hall-effect

linear current sensor chip. The in-line resistance is almost

negligible, so I put it in the output line to the battery. It is

completely isolated from the circuit it is sampling, and it outputs

nominal 185mV/A which can be measured by the ATtiny861

A/D at ADC0 using the 2.56V internal reference voltage. The ACS712

is a bipolar sensor, and it needs a way to indicate both positive and

negative currents. It does this by outputting 2.5V (assuming Vcc is

5.0V) when the current is zero. Since I'm using 2.56V as Aref, I can't

allow the voltage to increase with increasing current, so I wired the

sensor the other way around, so the Vout decreases with increasing

current. In this application, Vout goes from 2.50 volts at no current

to around 2.0 volts at max current. There's no problem dealing with

this in the software. There are defines for Vcc and the sensor transfer

function ("Sens"), which can vary from 180 to 190 mV/A according to the

spec sheet. You can measure

AVcc, and infer Sens from the accuracy of the current display. Note

that the resolution of the A/D is not quite up to the job, so at the

low end the readout goes from 0mA to 16mA to 27mA etc., but it's good

enough for this project.

* Sparkfun has another version of the ACS712, with

an op-amp built in, p/n SEN-08883, I

didn't use this part, please don't confuse them.

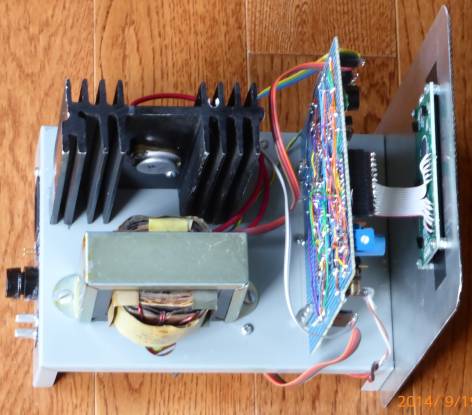

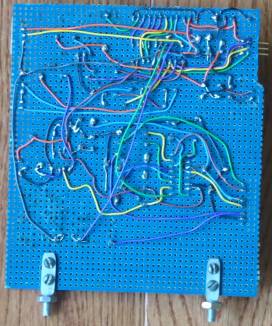

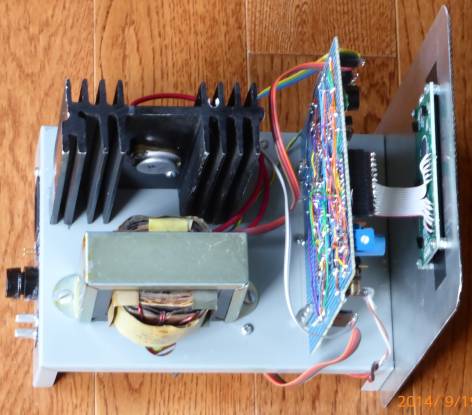

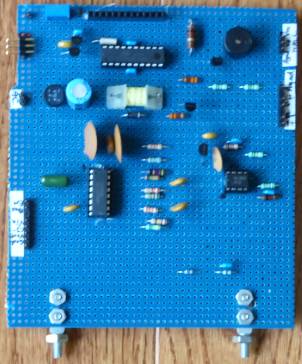

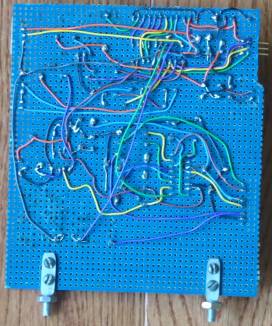

(Sorry

about the messy build. I usually don't plan things in much detail,

except to ensure all the parts will fit somewhere, and the front panel

looks decent. The case comes from a fleamarket minus the front panel

and

chassis, which I provided from my scrap bin.) You can see the ACS712

breakout in the right photo, on the right-hand side, wired between the

fuse holder and the wire going to the output connector.

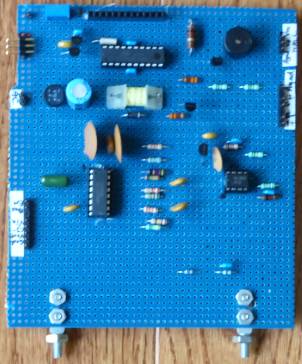

The ACS712 Hall-effect current sensor module.

The ACS712 Hall-effect current sensor module.

You should go over the calculations for 6 of the resistors

that control the UC3906 as per the spec sheet. (Perhaps your

battery requires a different float charge voltage, or you want a

different Voc.) After tediously doing this

a few times I finally wrote

this program

to

make it easier. The oddball resistance values for RA..RD can be

achieved by

placing two measured resistors in series. (Or parallel if you prefer.)

I use one

larger value close to the required resistance, then find a smaller

value resistor to make up the difference. Here are the parameters I

used and the calculated resistors:

| Id |

67 mA |

| Vf |

13.8

V |

| Voc |

14.3

V |

| Imax |

2.5 A |

| Vt |

10 V |

| It |

25 mA |

| Vin |

18 V |

| RA |

157.5K |

| RB |

14.15K |

| RC |

34.3K |

| RD |

789.5K |

| RS |

0.1 |

| RT |

220 |

RS

must be a 2W resistor, as it dissipates 0.6W or so. Use a 1%

resistor if you can, or a selected close value, since it controls the

charge current Imax.

Update - I have found that after calculating for a Vfloat of 13.8V,

the circuit actually provides a Vfloat closer to 13.6V. This is not a

problem, but if you are a perfectionist, you can take this into account

during the design stage and hopefully it will come out better.

It

is important in a project like this to build for the high current

sections. Keep in mind that the UC3906 monitors the battery voltage

inside the charger box, but the actual battery voltage at the end of a

cable may be different. Use heavy duty connectors and cable (and fuse

holder). A 0.5 ohm resistance in the path drops 1.25 Volts (!) at 2.5A,

which will throw off the UC3906 parameters quite a bit.

Select a good transformer for T1 (at least 3A) and heatsink

for Q2,

because it might run at Imax for a long time. I placed a 3 inch computer

fan on

the back of the cabinet, controlled by the microprocessor. The ATtiny461

has an onboard temperature sensor, so the fan is turned on either when

the current or the temperature is high enough.

The

ATtiny461 software is programmed to monitor the state of the charger

and report as much information as possible on the LCD. On line 1 it

shows the temperature and Vout. On line 2 it shows charge current and

the charger state. It tries to detect failure modes such as those

documented in my original SLA

charger project. When a fault is detected the beeper is

sounded and a message is displayed in place of the charger state, as

follows:

| Fault PI |

The UC3906 PI (Power Indicate) status is off.

Possible failed UC3906 or power supply. |

| Fault TM |

Charger has been in bulk (or over) charge for too long.

May indicate a bad battery. |

| Fault VO |

Charger

is in Float mode but Vout is too low. May indicate a failed UC3906. |

O=x SL=x

|

"Unknown

state" which my routine determine_state has not accounted for. For

example, when OC=0, SLC=1 which indicates float charge but the current

is too high.

|

Update

2016-07-25 I discovered a problem in the fault message handling and a

buffer overflow bug, and reworked some of the code.

When

a fault occurs the beeper sounds and the short message is displayed on

line 2. The fault will reset in 6 seconds and the program will carry

on. (Keep in mind that the UC3906 is not affected by this program, only

monitored. The only way to affect the UC3906 is to power cycle the

project.) If it is a hard fault it will re-occur, so the message will

stay on the display (and the beeper will keep sounding). I

have not been able to thoroughly test these fault modes so

far, so there is no assurance that they work. There are some defines in

main.c that specify the voltage and time for these failures you may

want to review. In any case a look at the display should tell you what

the charger is doing and if everything is OK.

2015-09

Update I realized that an ATtiny861 was not required and replaced it

with an ATtiny461A. The thermometer required recalibration, otherwise

no issues. The schematic still shows ATtiny861, however.

2016-11

Update. My unit started faulting and gave me the opportunity to look at

the fault handling code again. I reorganized the logic and made what I

hope are a few improvements.

Footnote. Greg, ZL2BZH, makes

the following observation: "One thing that can have an effect on the

project’s success is to remember that the IC tracks the ambient

temperature to adjust the reference voltage, to follow the necessary

voltages for lead acid cells at different temperatures. So it is

desirable to keep the IC away from any heat producing components."

Many thanks, Greg.

Further, I added R110 to

make the fan run slowly all the time to counter the small heat build-up

in the case during float charge.

Download WinAVR C

source code for the charger monitor

Back

to VE3LNY's AVR Projects Page

The ACS712 Hall-effect current sensor module.

The ACS712 Hall-effect current sensor module.