I made some minor changes from these drawings:

The VSWR pickup was I rotated.

Changed the mount for the beefy antenna switch, which required a lot of torgue, from posts to a piece of aluminum angle.

Island Tuner The Ultimate Transmatch design has some drawbacks at high load impedances where minimal output capacitance would be in shunt with the inductor, giving rise to a high-pass condition. This design fell out of favor to the T and SPC. On to the design. I want my tuner to have an antenna switch which allows selection of a dummy load, two coaxial outputs (Ant 1 and Ant 2), a longwire output, a balanced output and a direct position for coaxial Ant 1.

I want to have an internal SWR and Power indicator. For this I purchased the needed parts from Palstar, which sells a directional coupler, dual needle meter and meter board. Those will be incorporated in my tuner so I don’t need an external meter. Using a commercial product also saves me the hassle of sourcing the correct parts and reinventing the wheel and is far more accurate than anything I'd build.

|

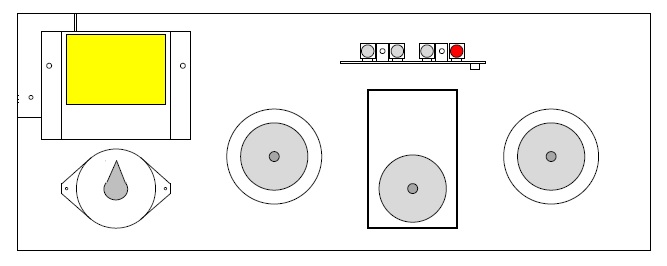

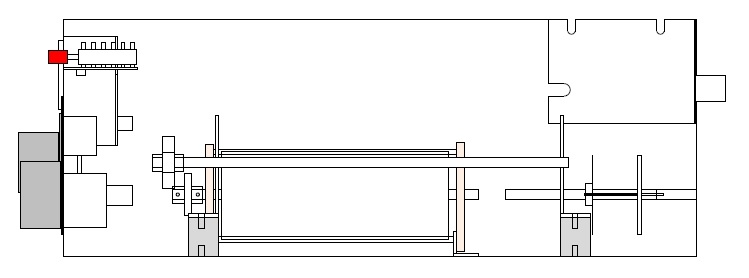

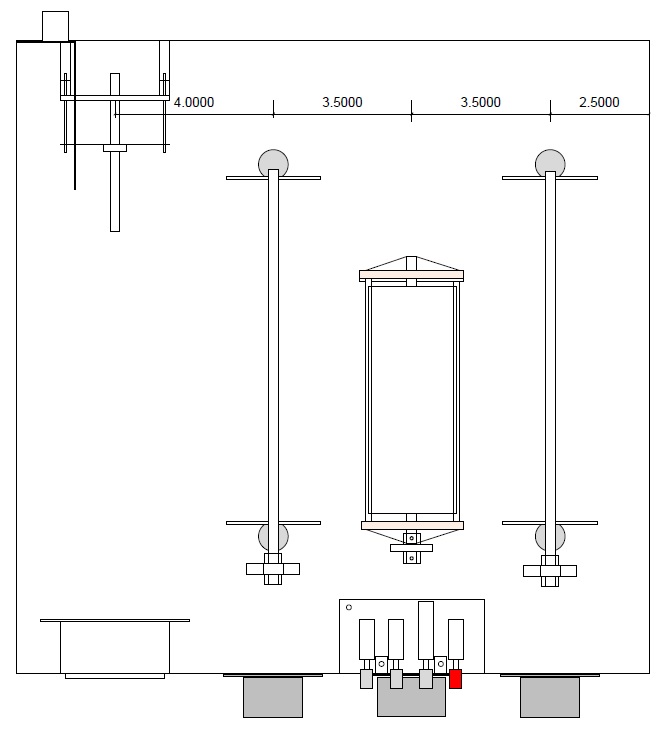

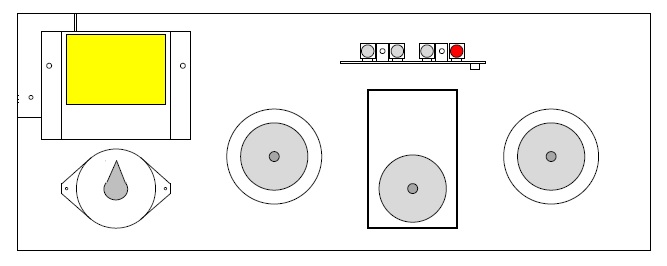

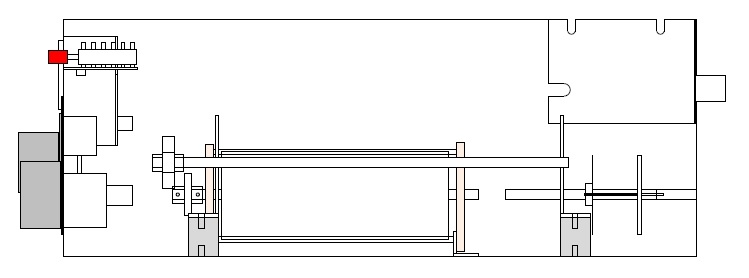

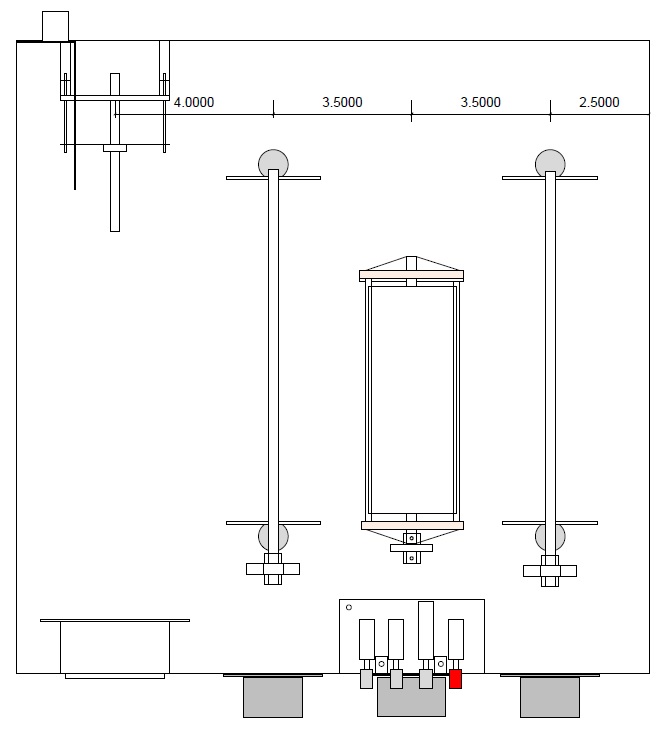

| I had drawn all of the components I planned to use in three different views so I could lay things out and take my measurements from there. Measure twice - Cut once! Planning is the key to any successful project. I made some minor changes from these drawings: The VSWR pickup was I rotated. Changed the mount for the beefy antenna switch, which required a lot of torgue, from posts to a piece of aluminum angle. |

|

|

|

| The caps and inductor get mounted |

| Connections are make from 3/8" copper straps which I then plated with Cool-Amp. Wide straps reduce the inductance which would be indroduced by wire.I used a flex coupling on the inductor to allow for any minor misalignment of the shaft to the counter dial. |

| Front panel drilled and cut. Large opening done with manual milling machine (files) from rough cuts, Extra care given to panel meter opening since that's visible. |

| Antenna switch mount and connections for antenna connectors. All are done with silver plated copper strips. |

| The balun was later mounted behind the inductor. Since I don't use balanced feeders, it was the last order of business. The balun is a 1:1 wound on a F-234-KC core from Bytemark. Tefzel wire and Scotch glasstape for that touch of craftsmanship. Wire from the balun was used to make the connections since it is pointless to add an additional connection point to it. Also since the balun is mounted in a way which it can move, vibration would weaken any additional connection points. |

Rear panel. Ant 1 can be fed direct or via tuner by front panel switch. |

Always sign your work! |

| Lettering used for this project is old school Datamark try transfer lettering. I've used it for years and its easy to lay out. Front panel is sealed with a few coats of clear spray and lettering on the back panel is sealed with their brand sealer, which is like clear fingernail polish. Love the look. Had I been willing to ship off the panel, I could have had it engraved (at great cost). |

| Ready for RF! |

This is my everyday tuner now. It handles the multiband (non-resonant) inverted L I am using on the island here very well and performs better than the heathkit tuner I was using. Rated for high power, if I ever go that route, but that also allows it to handle the odd impedances it has to work into without a problem.

|