LED Travel Clock

Although I've built a lot of

clocks over the years, I

needed one more, one I could take with me on a trip. Since size and

weight were a factor, I decided to look for a commercially built clock.

I found a few candidates and even bought one, but the display was

unsuitable. Then I found a clock

kit that looked good, from a Chinese outfit called Banggood, for a

very attractive price, which I bought. (Update: there are newer, less expensive models with more features available on ebay.) In case the link doesn't work

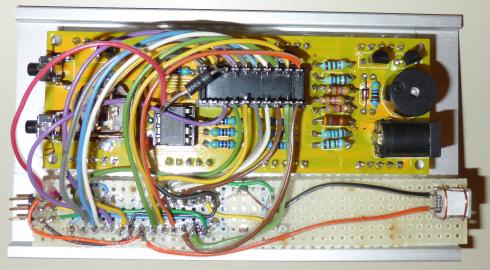

anymore, the clock (in its optional clear plastic case) looks like this:

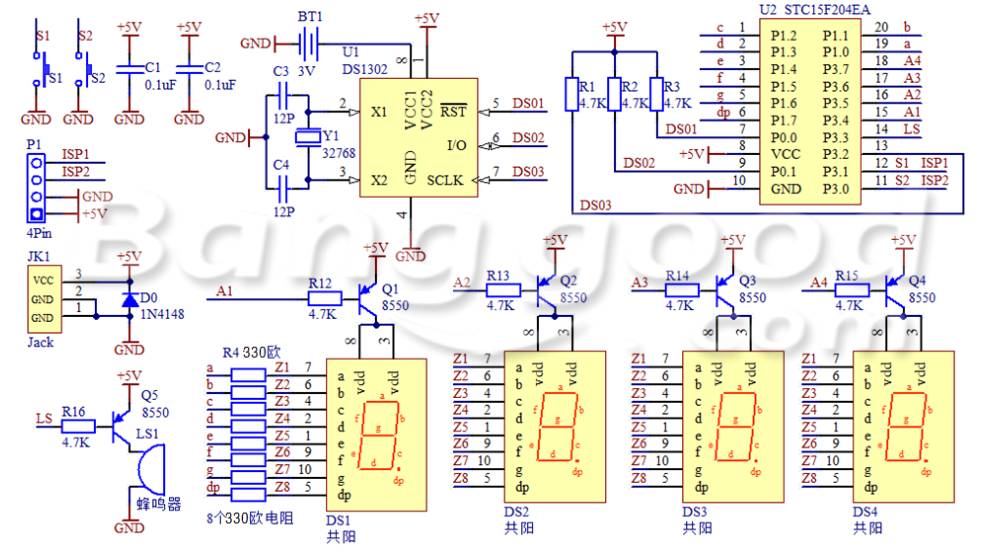

The

clock has a large bright (too bright for night use) LED display. It is

easy to build and looks great. It has a STC15F204EA microprocessor and

a DS1302 RTC, and two tiny pushbuttons on the side, which cannot be

reached when the clock is inside the optional case! Power is supplied

by a small 5V wall wart. Here is the spec

sheet. All the clock programming is done by these

two buttons, which is where the difficulties arise. Try as I might, I

could not consistantly program the clock. After wasting an hour, and because of the unreachable buttons, I

decided to build my own clock after all. But that display was so nice,

how could I make use of it? The problem was, the displays are soldered

on the bottom side of the PCB, so you lose access to the circuit board.

No way I could unsolder them either. I decided to take the following

approach:

- Throw out the optional plastic case

- Place the unit inside a larger case

- Build a daughter board with an ATmega88

- Using a 20 pin male header, connect the daughter

board to the relevant pins of the STC socket

- Include a rotary encoder, and ignore their

pushbuttons

- Replace

the 8 330 ohm LED current limiting resistors with 6.8K resistors*, to dim

the display. These could be unsoldered and removed from the top of the

circuit board thanks to the plated-through holes.

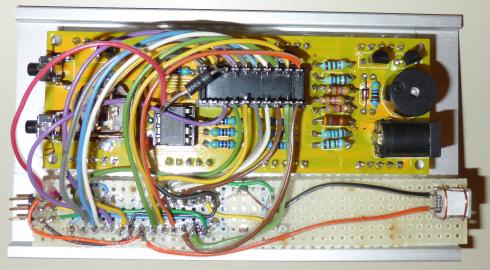

I

found a very nice aluminum project box in my collection, cut a large

hole for the LED display, and glued the original unit in place. I cut a

hole in the side panel for the power cord, which goes to the daughter

board. The rotary encoder is mounted on the daughter board, mounted to

the front panel which holds it all in place. Now the ATmega88 is in

control, and I know how to program it.

The daughter

board consists of the ATmega88, a power socket, a programming header, a

rotary encoder and a power line decoupling capacitor. I used the

original schematic, just assigning ATmega88 pins to the

functions

that the STC micro controlled.

| STC |

Function |

AVR |

| 1 P12 |

LED-c |

4 PD2 |

| 2 P13 |

LED-d |

5 PD3 |

| 3 P14 |

LED-e |

6 PD4 |

| 4 P15 |

LED-f |

11

PD5 |

| 5 P16 |

LED-g |

12

PD6 |

| 6 P17 |

LED-dp |

13

PD7 |

| 7 P00 |

DS1302

!RST |

16

PB2 |

| 8 Vcc |

+5 |

7 Vcc |

| 9 P01 |

DS1302

I/O |

9 PB6 |

| 10

Gnd |

Gnd |

8 Gnd |

| 11

P30 |

S2 |

nc |

| 12

P31 |

S1 |

nc |

| 13

P32 |

DS1302

SCLK |

10

PB7 |

| 14

P33 |

Beeper |

15

PB1 |

| 15

P34 |

LED-A1 |

23

PC0 |

| 16

P35 |

LED-A2 |

24

PC1 |

| 17

P36 |

LED-A3 |

25

PC2 |

| 18

P37 |

LED-A4 |

26

PC3 |

| 19

P10 |

LED-a |

2 PD0 |

| 20

P11 |

LED-b |

3 PD1 |

|

Enc-A |

27

PC4 |

|

Enc-B |

28

PC5 |

|

Enc-SW |

14

PB0 |

|

ISP 1 |

18

MISO |

|

ISP 3 |

19

SCLK |

|

ISP 4 |

17

MOSI |

|

ISP 5 |

1

!Reset |

|

A/D

pins not used |

20,

21, 22 |

Vcc is applied from the daughterboard to the main circuit

board through a diode such as 1N4001. I found this to be necessary

because without it, the LED displays do not turn on and off properly.

The common anode LED displays are switched using four PNP

transistors, which need their bases driven close to the Vcc rail to

turn off completely. With a Vcc of 5 volts, the ATmega88 output ports

turned on only deliver around 4.3V, insufficient to fully turn these

transistors off. The diode drops the main board Vcc enough so

that the transistors can be driven fully off.

The pushbutton

rotary encoder is a model EC11-1B-18T made by

Changzhou Xinze Electronic Co. It is very similar mechanically and

electrically to the CTS

series 290 rotary

encoder I used before. As a bonus it is easy to panel mount, (as long

as you can find a nut that fits it), and works quite well.

The

decimal point on the last digit indicates PM if on, and AM if off. The

decimals on digits 2 and 3 make up the colon between hours and minutes,

and are always on. The decimal on the first digit indicates whether the alarm

is on or off.

Programming

the clock is simple. Twisting the encoder knob turns the alarm on and off. Press

the

encoder button and programming mode is entered. If the alarm is on when

the button is pressed, the alarm time is displayed and may be

changed. Otherwise the clock time can be set. First hours blink, and

twisting the knob changes the hours. Press the button and minutes blink

and may be similarly changed. Press the button and you return to nornal

clock display. Keep in mind that when clock time programming is

complete, the time is updated in the DS1302 with seconds=zero.

When power is off the DS1302 is powered by its battery, a CR1220

coin cell. Alarm time and setting is stored in EEPROM so it will not be

lost.

*Yes

really. I tried 1K then 4.7K, both too bright in a dark room. Unless

you like an alarm clock+nite light. I suggest that if you build

the kit, use a 16 pin DIP socket in place of the 8 resistors, if it

fits. Then you can use a DIP resistor, then it's easy to try different

values. Update 2017-08: newer versions of this clock kit are available

that have filters that go over the LED display and improve the contrast

greatly. They also figured out how to make the programming buttons

accessible. But programming it is still a PITA, and it forgets all its

settings when the power fails.

Download C

source code for the travel clock

Back

to VE3LNY's AVR Project Page