PIC Cable Tester

I discovered a project here

for a network cable tester. It uses a few CMOS chips and a lot of LEDs

and can identify common ethernet cables (patch, cross). I was just

about to build it when I thought, why not do it with a microprocessor?

Of course it is more complicated, but also more flexible. The cable

type can be identified in the software, so extra connectors are not

required. Better still, any cable with 1 to 8 conductors can be tested,

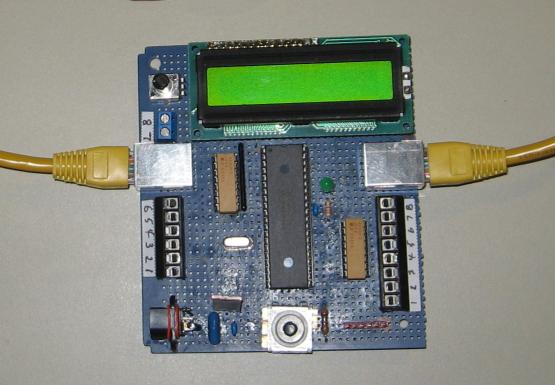

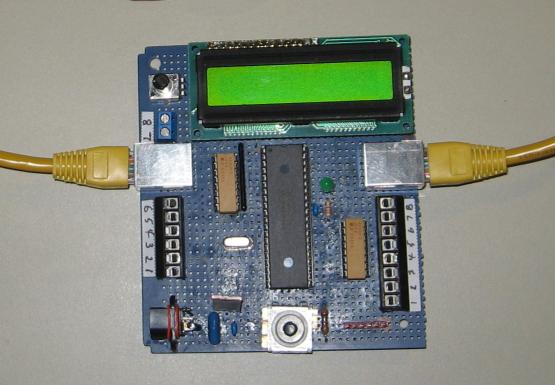

making the unit more useful. I selected a big 40-pin microprocessor,

the PIC16F877A, although the project would still fit in a PIC16F874A.

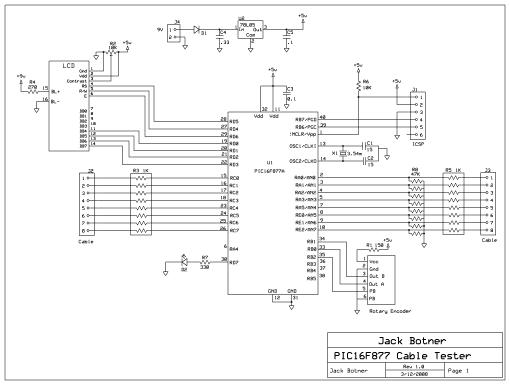

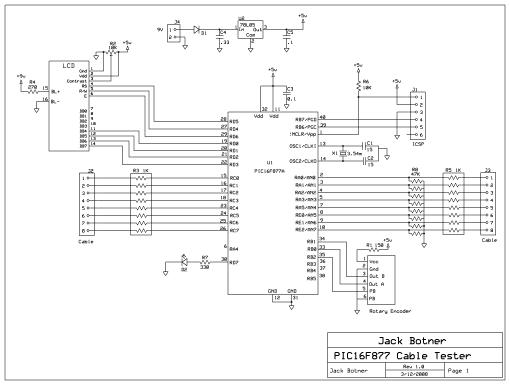

Pins RC0 through RC7 are defined as output pins and drive the

cable under test. The other end of the cable is connected to pins

RA0..RA3, RA5, and RE0..RE2, defined as inputs. I chose those pins

because they correspond to AN0..AN7, and early on I thought that it

might be possible to measure the resistance of the conductors somehow.

For the sake of simplicity I gave up on that idea. The R3 and R5

resistor networks are for protection of the input and output ports. I

thought about using diodes on the input side as well but ran out of

room on my project board. The R8 resistor network makes sure the input

pins sit at ground when not otherwise connected.

A standard 2X16 LCD module is used to display information. For input I use a rotary encoder with inegrated pushbutton, the Grayhill 62P22-L4, available from DigiKey as part

number GH7295-ND. (More information on this part can be found on my rotary encoder page.)

There is a LED on port RD7 which flashes on and off once a second,

which you can leave out if you like. I used a 3.54 MHz crystal from my

junkbox, but almost any clock frequency will work. I programmed the PIC

using my PICkit

2 and the ICSP header.

The

cable connects to two RJ45 sockets at J2 and J3. In addition, I placed

screw-on terminals so that other cables can be tested.

The

really interesting part of this project is the software. The rotary

encoder debouncing and decoding routines are in a separate module,

encoder.c. The rest of the code is in the main module. Timer1 is used

to generate 4 ms interrupts for debouncing the encoder. The mainline

runs through 4 steps. The 1st step prompts you to enter the number of

conductors in the cable under test, which you do by turning the

encoder. When ready, press the button, and step 2 runs a test on the

cable. An array of 8 bytes is used to map the cable connections. Each

byte in the array corresponds to one conductor, and each bit in a byte

corresponds to a conductor that it maps to. So for example, if

conductor 1 on one end of the cable connects to conductor 1 at the

other end, the 1st byte in the array is x'01'. If conductor 1 connects

to pin 8 at the other end, the byte would be x'80'. Each conductor is

activated in turn and the responses mapped at the other end.

Once

the cable has been analyzed, step 3 produces a report. The connections

of 2 conductors are displayed on the lcd. If there are more than 2

conductors, rotate the encoder to see the rest of the conductors, and

the list scrolls down or up. When done, press the button. The last step

only occurs when a recognized network cable is detected. The type of

cable (patch, cross, etc.) is displayed on the lcd. (More information on network cables here.) Press the button

again and you return to step 1.

If you work with particular

kinds of cables, you can easily adapt the hardware and software to

recognize those cables. Add connectors for your favorite cables to the

inputs and outputs, and customize the report code in step 4.

Download C

source code for the Cable Tester (

SourceBoost

BoostC)

Update (02/2009) I discovered an article in July 2006 QST

magazine, "A CAT5 Cable and Connector Tester" by K8AXW which describes

a simple CAT5 cable tester. This was followed up in Jan. 2007 QST

Technical Correspondence "Comments on the CAT5 Cable and

Connector Tester" by W0ZW, which describes why simple continuity

testing on a CAT5 cable is not sufficient. He says, "It is possible for

a cable to test good yet in fact be faulty". The problem is that DC

continuity testing does not ensure improper pairing of the twisted

pairs. When this happens, crosstalk is not reduced as intended, and the

cable can fail to work, or work erratically. Of course, my cable tester

does not test for proper pairing either.

Back

to VE3LNY's PIC Project Page