Old Lamp New LifeDecember 2018 The LampWaiting to be disposed there was very old accu-lamp, miner's style:

Originally there were three iron-nickel (Ni-Fe) cells in series having 3.6 V, but their life ended long time ago despite to "reviving magic"... Years ago I decided to replace Ni-Fe cells with nickel-cadmiun (Ni-Cd) ones and put charger into lamp to allow charging directly from power lines. The most difficult part of the process was to remove failed cells as their envelops were created directly in the lamp plastic body. After some effort I succeeded to remove them and I got enough space to place new cells and a charger.

Lamp reconstruction was more or less successful... Lamp was working short but charging long... The reason was partially low capacity of Ni-Cd cells, partially relative high energy consumption of the lamp bulb - 3,5V/0,6A. Then lamp was resting in peace for a years... ChargerNew idea to repeat reconstruction I got when I was doing charger for Li-ion cells which I used as replacement of Ni-Cd cells of my accu drill machine. Notebook Li-ion cells I used to replace Ni-Cd cells perfectly fitted to the box, but original charger was useless. It was providing lower voltage - only 9.6 V and additionally Li-ion cells require different charging procedure. But about that story sometimes later... Charging Li-ion cells requires constant current with limiting maximum voltage to 4,1 to 4,2 V when current should drop rapidly. It is easy to use popular LM317 for that purpose.

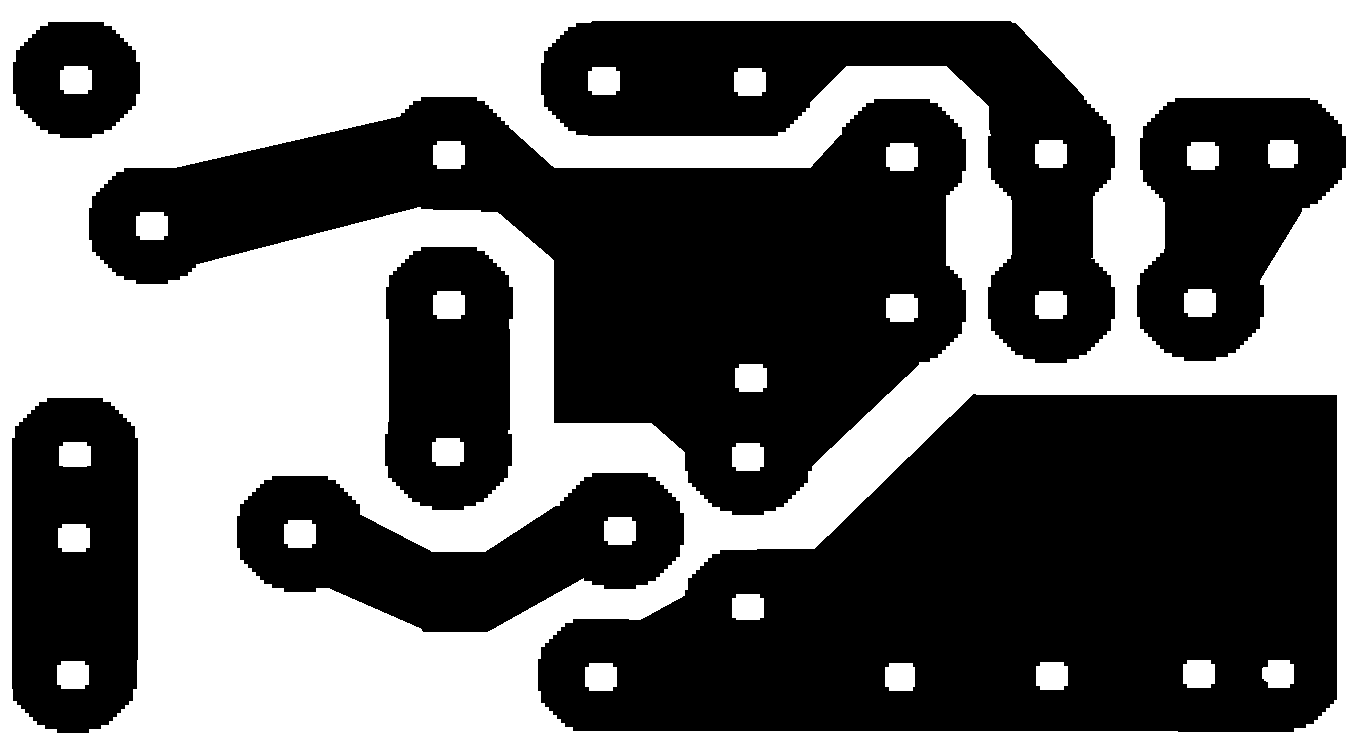

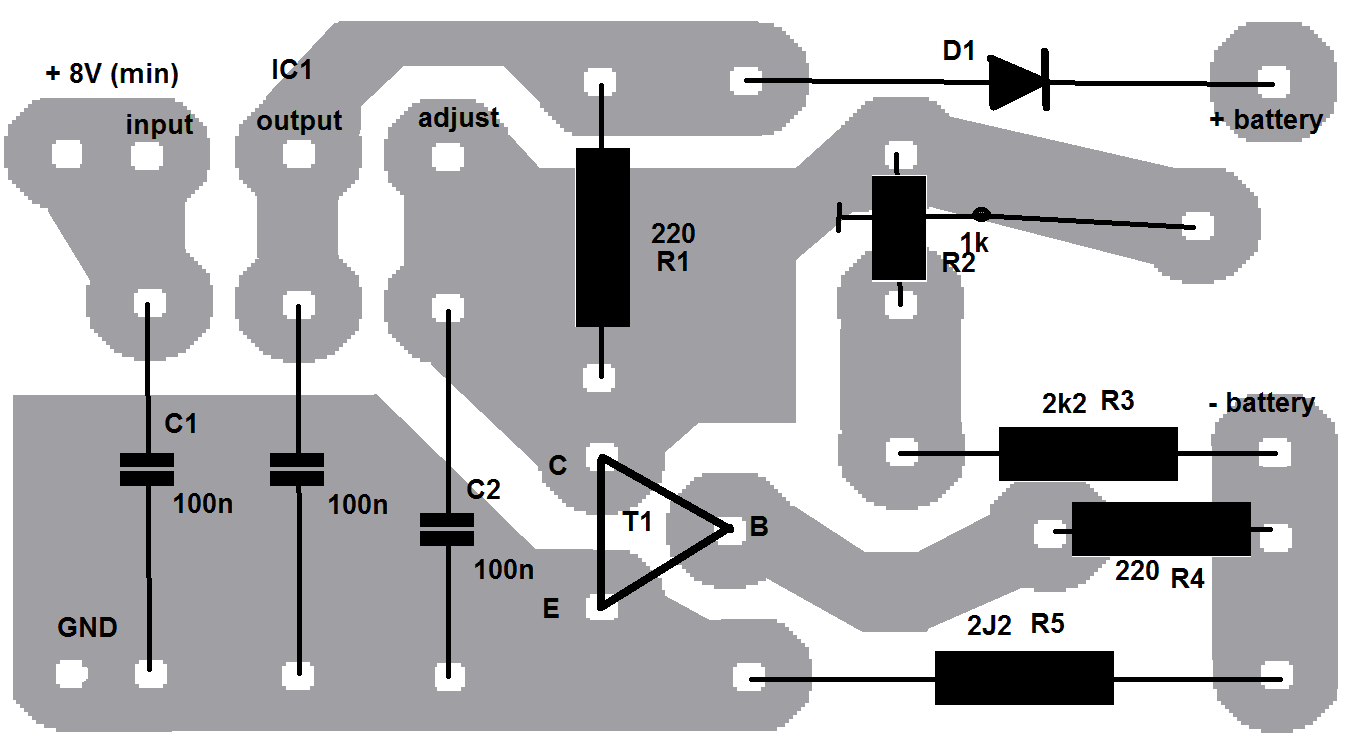

LM317 is constant voltage stabiliser with additional simple maximum current limiting circuit with transistor. Current through cells goes through resistor R5. If voltage on that resistor reaches transistor BE opening voltage, then transistor opens which is resulting in decreasing LM317 output voltage. It is simple and for practical purposes doesn't matter some temperature dependency and rough setting of limiting current. Presence of diode D1 should be explained - it's purpose is to block cells discharge over resistors R1 to R3 when not charged. Adding the diode brings small complication but without that there would be needed switch or some electronics logic to disconnect charger from cells when not charging. Complication is based on the fact, that it is required to set LM317 output voltage higher than 4.1 to 4.2 V. Additional voltage drop on diode has to be added. Practically it means, that output voltage is set with charged cells attached and it is adjusted to obtain 4.1 to 4.2 V on the fully charged cells. Regarding diode type - it is not necessary to use Shottky type, that one is required only in case power supply used has no voltage reserve (see below). If there is voltage reserve, then any Si diode can be used. Note, that it must safely withdraw charging current. With Shottky diode listed in the BOM LM317 voltage was 4.45 V. Additional diodes - combination of LED and standard or Shottky diodes - parallel to LM317 output is kind of charging level indicator. When diodes are successfully combined they start to open around 4.1 V and at 4.45 V they are quite bright, which means cells are fully charged. To continue charging is not dangerous neither for charged cells nor for diodes. Diodes are not on the PCB, they are wired to outer surface of the lamp body (one, the brightest one) to be allow monitoring of charging progress. LEDs of different colors have different working voltages. Even the same LED color but from different company can have different V-A characteristics. Classical LED diodes have working voltage around 2 V with current 10 to 20 mA. To find correct combination of diodes one must consider experimenting - it will require variable voltage power source, mA-meter in series with diode/diodes and good V-meter connected parallel with diode/diodes. The goal is to find a combination of diodes which starts to open around 4 V and is fully bright at 4.45 V (provided Shottky diode is used as mentioned above). PCB is single sided with dimensions 2,5x4,5 cm. LM317 is not placed on the PCB. It is wired to the lamp box outer surface with small cooler/piece of metal (PCB picture has original resolution 300 dpi)

Components placement has no problems, PCB is designed for classical components. Comparing to schematics there is additional condenser 100n as there was some space...

Charger power sourceCharger requires power source capable to deliver in minimum 300 - 400 mA at 8 V minimum. Classical way to fulfill those requirements is to use small transformer, diode bridge and a small electrolytic condenser. Modern way is to use switching power supply. To build some small one may not be a real problem, but question is if that's necessary. On the market there are cheap phone chargers, maybe some already rests in peace in the box. All current phone chargers are USB compatible providing 5 V and 1 A or more, which is not principial complication, but in era of first mobile phones there were also chargers serving different voltages/currents. Maybe they are waiting to be disposed or get second chance in some device. I have one such an old charger - it has declared 5 V/0.62 A on the body. After very carefull opening I got fully functional switching power supply. Brief inspection revealed that output side contains just diode, electrolytic condenser and a few resistors. Basic testing found that opened output voltage is over 9 V and at 300 mA output voltage is still about 8 V.

Warning: Li-ion cellsLi-ion cells are for a long time used as part of notebook batteries. In the battery there are usually 3x2 cells and on the battery there is specification 10.8 V and capacity in mAh or Ah. One Li-ion cell is charged to 4.1 to 4.2 V, which means that maximum battery voltage is 12.3 to 12.6 V. "10.8 V" means average working voltage, which means 3x3.6 V. Capacity of one Li-ion cell is in value of a few thousands of mAh, in my case 3.000 mAh.

After replacing notebook battery old one is supposed to be disposed to special container (depending on local conditions). If you'll try to open it, you can get a few still useful cells because not all cells are gone in the battery usually. In case of electronic failure even all cells can be in a very good shape. Battery opening is not easy task. It is even risky. In case of short circuit or cell penetration sear and/or fire or even explosion can happen. Be warned! In a successful case battery has to be decomposed to cells. Cells in doublets can stay as they are. All cells should be tested for charge/discharge, fault ones disposed. If some double seems fault it should be separated to cells and they should be tested individually. Result of the effort can be a few still useful cells. Li-ion cells are also available on the market. Comparing to those from notebook battery they will be usually without wired contacts. Attempt to solder wires has to be avoided - it can result in cell damage or even explosion. In case cells are without wires one should consider to found some holder design.

Lamp requires in minimum one Li-ion cell. If there is enough space then two cells should be a good compromise between working and charging time. In case of more powerful charger it is possible to use even more cells. Before combining cells they should be fully charged individually, then bridged using small bulb to let equilibrate voltages and only then permanently connected. Final battery should be eventually fully charged. Final remarksPurpose of this project was to get pleasure from returning things to life which otherwise would end up in litter. On the market there are relatively cheap and relatively good lamps so commercial site of this project is not important. But in case all components would be necessary to buy then the whole project would be probably nonsense. More powerful power source/charger is still an option to improve result. Phone chargers mentioned above - 5 V/1 A - are easy to get. In case of robust design with respect to output current limitation, which means it will not burn in a few minutes when empty Li-ion cell would be connected, then only problem is to decrease maximum output voltage to 4.1 to 4.2 V. Combination of Si rectifier diode and Shottky rectifier diode or so can solve the problem easily. Maybe I will try it sometimes.

This is |