Icom 746Pro

No-Transmit

Repair

Information Summary

A compilation of repair and modification notes for the 746Pro

"Sudden

Death" transmit problem.

Mark Brueggemann, K5LXP - Nov, 2004 - [email protected]

Executive Summary

Thanks to the internet and a variety of mailing

lists,

it's no secret there's a problem with the 746Pro transceiver. My

own 746Pro

crapped

out in less than 6 months of operation, so this problem was

involuntarily

foisted upon me. Rather than go through the Icom warranty mill I did my

own investigation into, and subsequent repairs of the

problem. Since that

time

I have discovered others who have done a similar effort and devised

their own solutions as well. It only made sense to incorporate

all

of

the known fixes into the radio at one time and take care of the

problem, no

matter which

specific issue is the root cause of the failure.

There are several

failure

modes

suspected as the cause of the "sudden death" 746 transmit problem. They

are:

- ESD event

- Heat

- Input switching transient

- [Reserved] (for Future Failure Discovery)

The last one is listed as

a bit of levity, but realistically I can't rule out any

other possible causes. If someome comes up

with

some hard data to support another yet-undiscovered problem, I'll be

happy

to add it to the list. When a radio fails it's difficult to know for

sure

which one of these was the root cause. The 746Pro no TX problem

always manifests

itself

in the form of a dead IC151, a broadband medium power amplifier IC.

Without

a sample of dead parts and subsequent detailed analysis, we may never

know

exactly what is taking these parts out. The good news is the the fix

for

the identifed suspected root causes is simple, inexpensive and readily

implemented by most hams with simple tools. The group of fixes

here, implemented in my own rig, have allowed to it operate longer than

it did with just the "protection diodes" Icom installed at the

factory.

Time will tell how robust these fixes will be, but to be sure without

them you

stand

a very good chance of joining the "sudden TX death" club. Yes,

the problem

should be

fixed by Icom, but that's not going to happen. Rather than complain

about

it, let's just fix it and enjoy this otherwise excellent transceiver.

IC151

Popped, or not?

You turn on your rig one fine day, hit the PTT and no joy.

You check the controls and no matter what you do, there's no transmit

power at all. You get that sinking feeling in the pit of your

stomach that you just became a member of the Sudden Death Club.

But how do you know for sure? The test to see if your IC151 is

bad is very simple. Take the

bottom cover off of the unit, and remove the shield covering the back

end of the RF Unit PCB. IC151 is at the back edge of

the RF Unit PCB facing out. Connect

the rig to 12V power, turn it on and set the controls as follows:

Frequency: 3.5MHz

Mode: FM

RF Power: Max Clockwise

Using even a basic oscilliscope, set the sweep for 1uS and amplitude

for 50mV per division. Press the [TRANSMIT] button on the rig and

you should see about 20mV P-P of RF on pin 1 (RF In), and 145 mV P-P of

RF on pin 5 (RF Out)

of IC151. If it's bad, you

will see little to no RF at pin 5. If you do see sufficient RF

at this point and your 746 isn't transmitting, the problem is elsewhere

and beyond the scope of this discussion.

Technical Data

I spent a bit of time characterizing

the thermal characteristics of IC151 based on the the information found

on OZ2M's

746 Page. It seemed

unlikely at first that a part dissipating only a third of a watt

could overheat but after reading the component's Data

Sheet and Application Note,

you

discover that the only path for heat to exit the chip is through it's

ground

leads. The copper pads for IC151 on the RF Unit PCB aren't

nearly

enough heatsink for this part. My subsequent bench measurements confirm

this. So connecting a heatsink to the ground legs is the only

effective cooling solution. Merely placing a heatsink on the

plastic package itself, while

it

wouldn't hurt, won't do any good either as the thermal resistance from

the

die

through the plastic package is very high. OZ2M shows several examples of homebrew

heatsinks that fit over the

existing

IC151.

If you read OZ2M's page you learn that

the IC-756Pro uses this same

RF amplifier IC as the 746Pro, and you don't hear of any of those

transceivers

having this sudden TX death problem. It turns out with the 756Pro,

power

is

turned on to the part only during transmit, while in the 746Pro the

part

is powered up 100% of the time. The part in

the 746Pro has to dissipate

it's 300mW or so of DC bias current even during

RX/standby. Since

amateur

transmit duty cycles are so low it's no suprise that the IC in the

756Pro

isn't failing very often, if at all. There is also less chance of

an unpowered part being damaged than a powered one. So it seems

if you could

mimic the 756Pro switched TX VCC circuitry, you might

similarly reduce

your chances of failure in the

746Pro as well. There

isn't any convenient source of TX

switched 5V near IC151, but there is a source of TX switched 8V.

Using a zener diode from the 8V source provides the TX switched VCC to

IC151 in the 746Pro.

Lastly, based on the experiments

performed by Steve, NB30 that he graciously shared with the 746 Yahoo

Group and gave me permission to quote here, shows there is some

validity to the ESD sensitivity claimed by Icom. Adding the

diodes to the HRX line (the 'protection diode fix') while a step in the

right direction, is a poor stopgap

to mitigate this problem. ESD can contain a significant amount of

energy, certainly more than what it would take to blow the PIN diodes,

and the next part in line, IC151. A better solution is to use a

choke,

which is virtually impossible to damage

with ESD. Additionally, Steve identified a potentially damaging

transient to the input of IC151, along with a suggested fix. The

text of his tests and conclusions can be found here:

Email and ListServe

Discussions

|

|

|

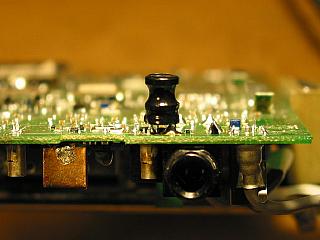

IC151 undergoing thermal testing using a mockup heatsink.

|

A view of

the competed SSOIC installation on the SOIC pads, along with the

homebrew heatsink. |

STANDARD

DISCLAIMER

If you weren't already aware that the

746Pro is comprised mostly of

0603 (60x30mil) size surface mount parts, you're about to discover

it. While performing the fixes below are basically no more

difficult than installing the optional high stability oscillator

module, not every ham posesses the skills required to perform

them. If SMT makes you long for the days of Heathkits then maybe

this isn't for you. If you go ahead anyway and hose it up, don't

blame me, I'm not the one holding the iron. And no, I'm not in

the business of fixing ham radios but I'll

gladly help folks any other way I can. The fixes described here

worked fine on my own rig but due to circumstances beyond my control I

cannot guarantee their efficacy in any other unit. Proceed at

your own peril. (Scary, eh?)

What

you'll need.

You're going to need the following

parts, Digi-Key

part numbers are shown but they may be alternately sourced as

necessary.

1ea IC151 RF

Amp: Icom# 1110001890, DK#

UPG1678GVCT-ND

2ea SOT PIN Diodes:

1SV252, Icom# 91213606, Substitute- DK# BAT54SWT1OSCT-ND

1ea .01uF 0603 X7R

Cap:

DK#399-3189-1-ND

1ea 1 millihenry molded

axial leaded

Choke: DK# TK4312-ND

1ea 2.7V Zener: DK#

MMSZ5223BDICT-ND

The UPG1678 from Digi-Key is an SS08

package, not

an S08 as originally used in the radio. If you're careful, you

can bend the leads out and get them to fit on the S08 pads.

Alternatively you can get the exact replacement

from Icom. If you're reading this before your radio died and are

doing the fix as

a preventative measure, you can leave it alone.

I couldn't find a retail (or even OEM)

source for the 1SV252 diodes,

so the most

convenient source becomes Icom for those. If you don't care about using

"genuine" Icom replacement parts, the BAT54 diodes from

Digi-Key are a form/fit/function

replacement and I think a better substitute than the original.

While it may seem superfluous, I would order at

least two sets

of everything. This will cover at least one botched attempt or

lost part. Having spares on hand will save you much time and

effort than

if you'd only ordered one, had a problem, and had to repeat the order

and wait. It's only a few extra bucks.

Something you may consider doing while

having your 746Pro on the operating table is to install the CR-282 High

Stability Oscillator module. If you operate much on 2 or 6M weak

signal modes, the 7ppm frequency (in)stability of the 746Pro is pretty

noticeable. You'll have the radio apart to that point anyway, and

you can fix

two problems at once (drift and sudden TX death). Just a thought.

Component

Installation Details

Refer to the

diagrams and photos for

placement of the new/replacement parts. Photos are clickable for

a high

resolution view.

The 1SV252 SOT diodes are the ESD

protection

diodes. If they aren't present in your radio, it would be a good

idea

to install them at this point. Even if your radio already has

these installed from the

factory,

it might not be a bad idea to replace them. If your IC151 was

blown

by ESD, it's a given that one or both of the diodes are fried or

weakened

and

should be replaced. Even

though their overall effectiveness is questionable, it doesn't hurt to

put them

in. You will have to remove the RF

Unit PCB to get to the backside of the board to install/replace the

diodes. It will help to remove the small shield that covers one

of them. Details on how to remove the RF Unit PCB can be found on

page 91 in

the

746Pro Instruction Manual, in the section that describes how to install

the high stability oscillator module.

After the diodes are in and the shield

soldered

back in place, trim the leads of the 1mH choke to about 1/8" and solder

it

on the

bottom of the PC board connected between the pad for

the center pin of the HRX connector (J1) and the PCB groundplane.

You will have to scrape away some solder mask on the groundplane to

expose the copper. That should

shunt any errant DC and static that should come down the HRX pipe. This

is

the intended function of the Icom diode fix, but a choke is a lot less

likely to get

blown out as the diodes are. This completes work on the bottom

side of the PCB.

|

|

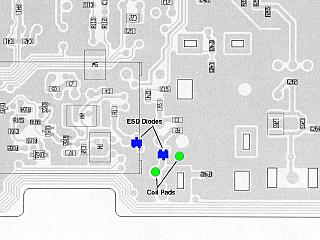

This diagram shows the location of

the "protection diodes" and the

soldering points for the choke.

|

Here is a view of the PCB with the

choke soldered in place. There is

plenty of room for the choke even

standing up like it is.

|

On the top side of the PCB, R&R C154 with

the .01 cap. That takes care of

the RX-TX switching transient issue.

If your IC151 is dead you will have to

remove and

replace it. If you order it from Icom you'll get an exact

form/fit/function S08

replacement. If you order it from Digi-Key or Mouser you'll get one in

a different package, as the original SO8 version was obsoleted by

NEC/CEL some time ago.

The two

versions

are functionally and electrically interchangeable. It is possible

to fit the SS08 version on the S08 pads, but will take some lead

bending/extending

and careful soldering. If anyone has a source for real S08 UPG1678's other than Icom I'd love to hear

about it. The only sources I've found are obsolete parts brokers

that will only sell them by the reel.

You may consider adding a heatsink at

this point

as described on OZ2M's webpage, though fabricating one to work with the

tiny SS08 version can be a challenge. I made a couple attempts at

making a

heatsink before I finally came up with one that was good both

electrically and

mechanically.

Unfortunately it's not something most hams would probably be

comfortable

in dealing with. This IC is barely 1/8" square, including the

pins. It fits comfortably on the end of a pencil eraser. I

used some 18ga copper sheet from a hobby

store for heatsink material. It had to be made out of

several small pieces, otherwise it worked too well as a heatsink and I

couldn't get it hot enough to melt solder on it. I

made the base by filing away the areas where the SO8's input, output

and Vcc pads

were

on the PCB. Then I bent the SSO8's input, output and Vcc leads up so

they

wouldn't touch the copper ground/heatsink. Kapton tape went over

the

PCB

where IC151 resides to insulate a hot via there. I tinned everything,

fluxed

it and in one step using an 800F iron I flowed the copper heatsink base

to the PCB ground pads, and the SSO8 IC to the copper heatsink base all

at once. Then in a second step, I soldered two square copper fins

to

the tabs on the base. Now, since the group of fixes detailed here

includes

switched TX VCC just like the 756Pro, which doesn't have a heatsink and

doesn't suffer the sudden TX death problem, it may

be overkill to heatsink the part. It's up to you.

The last step is to install the zener

which will

switch

power to IC151 only during transmit. Remove R157 and solder it standing

up on it's pad closest to IC151. Solder the anode end of the

zener

to the top end of R157. Using some 30ga wire wrap wire, connect the

cathode end of the zener to the end of R156 closest to IC151 (the TX

switched 8V point) as shown in the

PCB diagram.

Between the voltage drop of the zener diode and R157, IC151 sees about

4.7VDC during transmit, which is perfect.

|

|

|

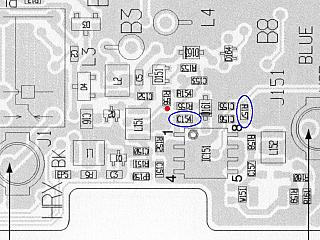

This diagram shows where the various affected components

are located on the top side of the PCB. The red dot indicates the

TX 8V connection

point.

|

This is a view of the competed mods done to my own

746Pro..

|

Smoke Test

That completes all the mods that are known to date. Button it

back up, put the fire to it, and if everything went right your 746Pro

is once again a happy camper. It shouldn't require any alignment

or other adjustments. Any slight differences between the old and

new amplifier IC is automatically compensated for since this stage is

within the ALC loop. A while back, Allen AE0Z posted a question

on the 746Pro Yahoo Group page

wondering if the switched TX VCC modification contributed to any QSK CW

bit

truncation.

To verify this I "unmodified" mine, tested the CW keyup delay, then

tested it again with

the switched TX voltage in place. No measureable difference was noted

between

the two (about 12mS). Now, rather than push your luck again, this

would

be a good time to install some quality DC shunt type arrestors on the

feedlines coming into the shack, such as the ones available from

Array

Solutions.

Conclusion

It mystifies me why Icom won't issue a

service bulletin regarding this defect. The

official company position is that it's not a common problem, but if you

have a problem with your rig under warranty it will be repaired at no

charge.

While this is a safe position for the company to take, it is little

consolation

for

someone who just dropped in the neighborhood of 1.5 kilobucks on a new

rig, and now has to pay UPS $30 in shipping and insurance to ship the

rig

to Bellevue, WA. Plus be without it for a number of weeks until

they

get

it repaired and returned. There

is a page at Icom's website detailing the ESD

diode fix but they don't explain

why units with the ESD diodes

installed

are still failing. Interestingly, they state, "ICOM America

service

records show that the failure rate of this part has been reduced to

1/10th of the previous value." Gee, they almost fixed it.

What I found especially amusing is their mention

about

the heat issue- "Our service technicians do not see any discoloration

of

the circuit board or the deformation of parts that are the symptoms of

overheating." It's pretty ignorant of them to associate melted

components

and discolored copper before suspecting an overheated component. Why

they are so afraid of admitting any

problem

with the rig is a mystery. With such a complex piece of equipment and

limited

development and testing budget (and likely limited profit margin to

boot),

it's no surprise something like this could sneak past the development

engineers.

I can accept that but repeated denying there is any fault is insulting

the intelligence of myself and other hams out here that do design work

and have reasonable evidence that there is a design deficiency.

It says on the back of my Icom manuals, "Count on us!". I wonder

what for, certainly not for customer satisfaction. Makes you want

to buy a different brand. Problem is, it's no greener on the

other side of that fence either.

�