A

Re-Manufactured Hammarlund

SP-600

Receiver

***

YOU'VE GOT TO BE KIDDING! ***

When first asked if I were

interested in undertaking the restoration and overhaul of

this receiver, and that it was a "basket case", I informed the owner

that it was probably best to use the components as spare parts for his

other SP-600 receiver (a military R-274C/FRR version).

However, when he told me

that if I undertook the task, I could have my pick of the litter, I

decided to give it a shot. I felt that 50 years of

home-brewing and repairing radio equipment of all genres gave me a good

background for the task.

Right from the start I told

the owner that I preferred to keep the factory wired unit as my own,

and this was fine with him. He wanted some modifications

performed on his receiver anyway, and these were easiest to perform

during the construction phase. The modifications

performed are listed at the end of this article, followed by PICTURES

of the COMPLETED unit. There were NO pictures

taken showing it's condition when it arrived here because I didn't have

access to a good camera.

Later, upon seeing the

actual unit I nearly changed my mind. The set was an empty

aluminum chassis, all the tube sockets, IF transformers, terminal

strips etc were in boxes and plastic bags. A clean and shiny

chassis, but bare none the less. The only parts installed on

the chassis were the power transformer and two filter chokes.

A local ham friend of mine

saw the receiver in this state and laughed out loud. Another

friend wasn't even 'that' kind and told me in no uncertain terms that I

was crazy to undertake such a task.

Luckily, ALL

vital components and necessary hardware (brackets, spacers, terminal

strips etc), except for the S meter were among the bags and

boxes. The

resistors and capacitors needed for the construction of the receiver,

as well as overhaul of the factory wired unit were provided by the

owner of the receivers.

The front panel was

unattached, as was the RF deck. The RF deck (big square metal

box in the center of the receiver) was the one bright spot in the

entire receiver. It was essentially intact and unmolested, with all

turret coils etc installed.

To make sure that the

overall project was worth doing, the RF deck was the first item to get

inspected, overhauled and recapped. Without a good RF deck

the receiver would be worthless. After it was recapped and

some mechanical cleaning and adjustments made the unit actually had a

smoother tuning mechanism than the one in my personal SP-600.

This was encouraging.

***

THE PREPARATION ***

At this point all the

components were prepared and cleaned up. Solder and old wires

were removed from the tube sockets, IF cans, terminal strips

etc. All parts that were to be recycled were examined for

damage. Needed components like resistors, capacitors, various

colors of wire etc were procured (provided by the owner).

Then all the

BBOD's (Black Beauties of Death) and out of tolerance

resistors etc in each IF can, BFO can, Second Mixer can and so forth

were replaced. The existing Mica capacitors were left in

place. The cans were serviced at this point so that

they could be dropped into the chassis without having to stop and

service each one during construction, possibly missing a BBOD.

***

RECONSTRUCTION BEGINS ***

Finally we were ready to

begin the actual re-construction process of this old

boatanchor. To help this go smoothly I first printed the

military TM11-851 manual and put it in a binder. This is an

excellent resource with all the schematics, parts lists and even

drawings showing actual component placement and wiring. Not

your usual skimpy little instruction manual.

All the tube sockets were

installed with their proper orientation, with at least one ground lug

for each. The power supply was wired and all filament and B+

distribution lines run before any small components were

installed. Any tube socket pins that were tied directly to

ground were grounded along with the center ground pin. Most of these

grounds were NOT soldered at this time. This preparation made

it much easier to neatly route the wires in cable harness form, using

Tie wraps as guides to keep the wires in order.

After the power supply was

wired, the audio section, comprised of the 6V6 and 12AU7 tubes was

wired. From this time on the wiring pattern basically

followed signal flow, starting with the second mixer/455KC IF gate

tube, through the IF strip from the first to last stages, followed by

the detector and AGC sections.

Special care was taken to

insure that all proper wiring practices were observed so as to

eliminate any possibility of instability. In wiring the IF

strip, the side panel was removed and the Bandswitch was NOT installed

until all IF stage wiring was completed and checked for accuracy and

proper continuity, TWICE. It is much easier to

work on the IF strip without the switch and side panel in place.

After all the basic chassis

wiring was completed it was time to consider installing the RF deck

into the main chassis. This needs to be done BEFORE the front

panel is mounted. All wiring to the front panel up to this point was

done by laying the panel up against the front of the set, putting the

switch or control in it's proper place and wiring it up so that the

leads would be of correct length/routing. Then the controls were

allowed to "dangle" by their leads. By bundling and tie

wrapping all the wires into a harness, most of the parts remained in

place until final assembly.

All new power connecting

wires were installed on the RF deck. There

was one glitch at this point. The cover on the

RF deck said it was version JX-14, which should have had 7

wires. However, this one only had 5 wires! Pulling

the tube module out of the deck again disclosed that this was NOT a

JX14, so I went ahead and wired it as a 5 wire unit. I'd

already mounted the power supply resistors for a JX14 and these were

just left in place as a bleeder resistor.

After resolving the RF deck

version dilemma, installation of the RF deck went well with no further

problems. The front panel was installed along with front

panel controls and switches. Shaft couplers were installed on

the BFO, Bandwidth and Xtal Phasing shafts and the knobs

installed. NO S meter has yet been installed as the owner

wants to make a scale for the generic meter he chose to use.

***

IT'S LOOKING LIKE A RADIO NOW ***

At this point the wiring of

every tube, transformer, control, terminal strip and switch were

checked for errors, TWICE.

A few connections which had been intentionally left unsoldered were

soldered, after ascertaining that no further work was needed at that

location (mostly grounds and B+ and AGC lines etc).

All tie wraps were cinched

up tight and additional tie wraps added to make for nice, neat wire

bundles. Routing of all wires was checked for any pinched or damaged

wires.

***

CHECK THE TUBES ***

The owner had provided all

the needed tubes for the receiver, along with some extras.

Some were new in boxes, but most were used tubes, either in boxes or

baggies. Since an untested tube is an unknown liability, and

this set hadn't played since the last millennium I wanted to be sure I

had good tubes.

So, I fired up the Hickock

800 A and tested each and every one. It's a good thing I

did. I ran into a number of very bad tubes, some weak and

some shorted etc. One brand new 6BE6 had a dead short!

***

POWER ON TESTING BEGINS ***

Then all tubes were inserted

into the unit, EXCEPT for the 5R4 rectifier. The radio was

plugged into a variac and brought up to about quarter Voltage so that I

could check the bias (modified with Silicon rectifiers) and filament

circuits. Since that didn't let the smoke out of anything I

went ahead and applied full power. The bias supply was

correct and the tube filaments lit.

So then I got brave and

plugged in the 5R4 B+ rectifier tube. With a Voltmeter

monitoring the B+ line and a set of headphones on my head, I gingerly

turned on the power (NO partial Voltage this time). The

Volume control was turned all the way down and I didn't even hear a

"hum".

Turning the volume control

up the receiver still seemed to be dead. OH NO!

However, touching the center pin of the volume control with my finger

showed that the audio stages were working as expected, but there was

absolutely NO RF noise. Turning the BFO on did create a hiss,

indicating that the BFO and product detector (another modification) was

working. But there were absolutely no stations, not even the local

blockbusters.

***

TIME TO TROUBLESHOOT ***

Well, nobody said this was

going to be easy, but I had hoped to at least hear something.

I tested the Voltages on ALL of the IF tubes etc. Every

indication was that the IF section was dead, but all Voltages checked

good and I couldn't find any wiring errors!

Time to dig out the test

gear. But first I decided to take the 455KC output from my

SP-600 (on an "Oldies" station) and use it as a known signal source to

see if I could track down the dead stage. Starting at the

detector and working my way back through the IF strip, I was able to

hear the "Oldies" through the entire strip, but couldn't hear any

difference or increase in signal strength as I progressed through more

stages.

Hmm. What's going

on here. Then I thought, hey, the signal from the receiver is

probably too strong and overloading the IF strip. So, I

dropped the RF gain of the working receiver, turned the Audio gain way

up, then turned the RF gain down further until I could just barely hear

the station in the test receiver.

***

NOW WE'RE GETTING SOMEWHERE ***

This time, when I started at

the detector and went back stage by stage I could hear the actual

difference each stage made. I also peaked each IF transformer

as I went through the set. MOST of the IF adjustments were

way off, and not by the same amount or in the same direction.

After going through the IF

strip in this manner I disconnected the signal from the test

receiver. Upon again checking with an antenna,

VOILA! I had radio stations

Checking all the bandwidth

positions showed that it was functioning as it should and the receiver

was ready to receive a full alignment and burn-in. But first

the radio was run for several hours to make sure that nothing would die

an early death.

A thorough alignment was

completed with no unforeseen problems developing. Most of the

bands were fairly close to begin with (Indicating the previous owner

didn't have "Screwdriver-itus", at least in regards to the RF

deck). The two lowest bands were "dead on".

***

MODIFICATIONS PERFORMED ***

As I mentioned at the

beginning of this article, the owner wanted a number of modifications

on the receiver. Here is a description of what was done.

1. Eliminate the

Send/Rec, Limiter and Meter switches to allow use of these for other

purposes.

2. Eliminating the

limiter and AF meter function allowed the 6AL5 tube and associated

circuitry for these functions to be eliminated.

3. The 6AL5 Bias

rectifier was eliminated and 1N4007 silicon diodes wired in it's place,

on a terminal strip mounted to the rear panel where the bathtub

capacitors had been mounted. Also, the bathtubs were replaced

by 22uF/160VDC capacitors mounted to another terminal strip adjacent to

the first.

4. BFO:

For some reason the 7 pin BFO tube socket hole had been re-punched for

a 9 pin socket. So, a 6U8 tube was used in that location for

the BFO and BFO buffer stage. Using the Pentode side of the

6U8 allowed the elimination of the 6BA6 factory buffer

stage. There is a 150 Ohm resistor in the Cathode

of the Buffer stage, bypassed with a .1uF capacitor. A .5mH RF choke

was used in the plate of the buffer stage with parallel capacitors to

comprise a low "Q" tuned circuit at 455KC. The Buffer

is coupled to the 6BE6 product detector through a .001uF

capacitor and 30K "BFO Injection potentiometer.

5. Product

Detector: A conventional 6BE6 product detector circuit was

used. IF signal for this stage was tapped from the same point

that feeds the IF driver stage grid as I felt the signal level at the

output of the IF driver would be stronger than was needed and would

overload the product detector. The DPDT Mod/CW switch selects

either Product or AM detector on one side while the other side applies

the regulated B+ to the triode of the 6U8 tube (BFO).

The unused limiter switch was used to select the Slow AGC

capacitor (.22uF), formerly switched by the Mod/CW switch.

6. S Meter

Circuit: As the owner wished to use a generic 1mA meter

movement for his S meter, an Amplifier just for this function had to be

created. This was installed in the tube socket normally

occupied by the BFO buffer stage. It uses a 6C4 triode tube

and is the same circuit that is used in the Hammarlund HQ-180

receiver. Being a bridge circuit there are two controls, one

to zero the meter and another to control the meter sensitivity.

7. Pre-Xtal filter

IF output: The owner wanted to use a panadapter with this

set So, a 6.2pF capacitor was connected to the plates of the

455KC gate/2nd mixer stage and connected to a terminal strip adjacent

to the tube to allow the connection of a coax cable to the rear panel

SO-239 IF output Jack. NO IF CATHODE FOLLOWER was installed

in this receiver, leaving one side of the 12AU7 unused.

8. An IF gain

control was added to the first IF amplifier stage, as shown in the

military modifications supplement. This was mounted adjacent

to the IF amplifier tube where somebody had drilled a hole for some

unknown reason (Each of the IF stages had such a hole drilled, suitable

for a control).

9. A single point

"Star" grounding system was used for the power supply, in the vicinity

of the Filter chokes. Shielded wire was run from the

Headphone winding of the output transformer to the headphone jack, with

a "single point ground" located at the headphone jack. This

made for a VERY quiet audio stage with NO hum whatsoever audible in the

headset.

***

SO, HOW DOES IT PLAY? ***

In comparing it against the

factory wired unit that I have here, it was very difficult to hear any

difference at all between the sets, either on strong local broadcast

stations OR weak shortwave stations. HOWEVER, there is NO hum

in the headset, and, in listening to SSB or CW the

improved BFO and product detector circuitry were clearly superior to

the original Hammarlund circuit! Of course that does nothing

for the fast tuning rate on the higher ham bands. The

smoothness of the tuning mechanism is definitely much better in the

re-manufactured unit."

The owners remarks when he

picked up the receiver? "Man, that's

really clear sound"!

FINALLY,

I WOULD LIKE TO THANK ALL THE KIND FOLKS WHO GAVE ME ADVICE ON THE

BOATANCHOR AND HAMMARLUND MAIL REFLECTORS. IT MADE THE JOB GO

A LOT SMOOTHER THAN IT MIGHT HAVE OTHERWISE GONE!

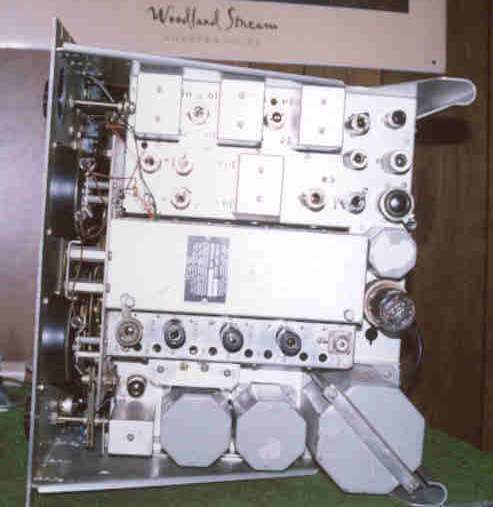

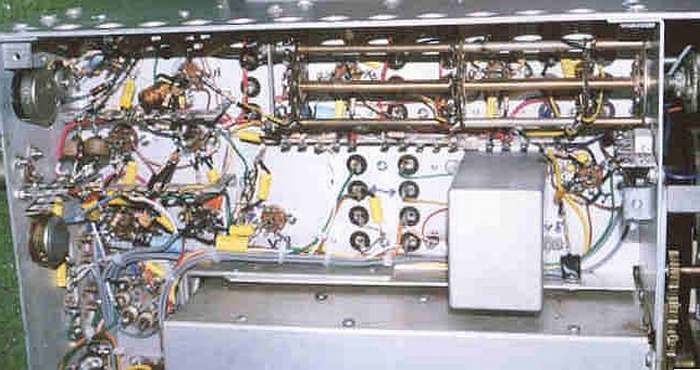

Full Under Chassis view

of completed SP-600

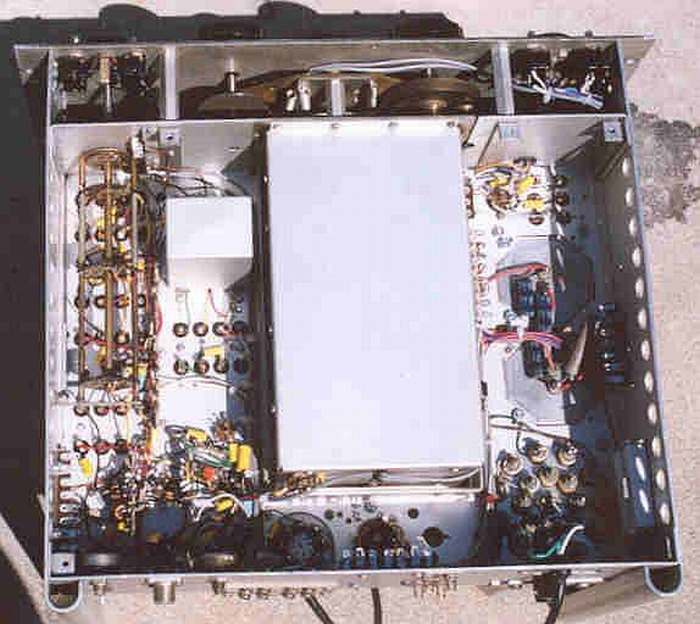

Another full Under-Chassis view

of completed SP-600

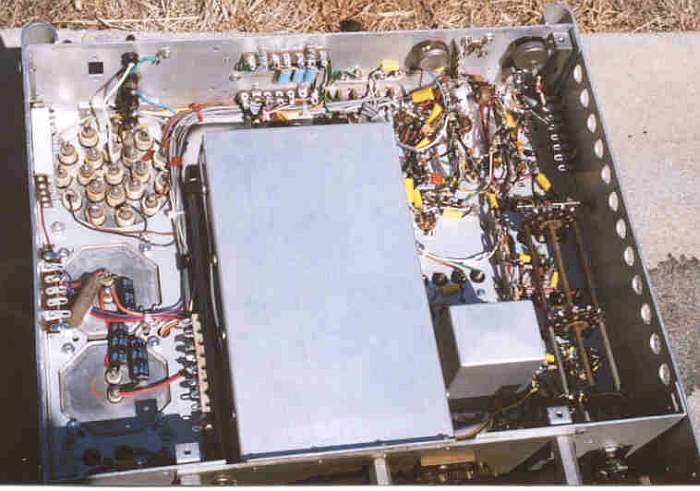

Close-up Under Chassis

view of Power Supply section

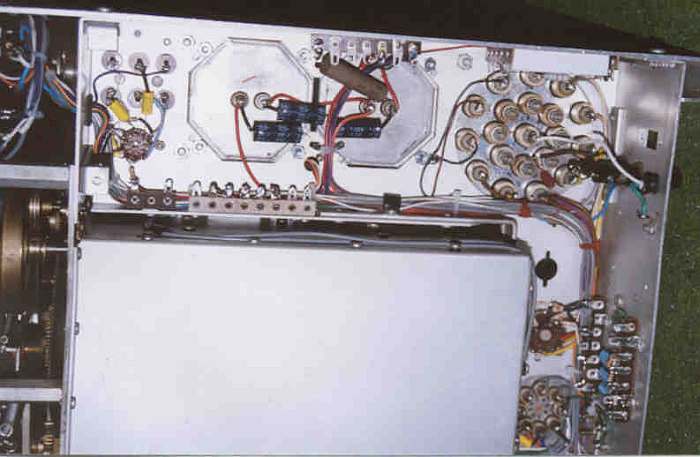

Close-up Under Chassis

view of IF Strip

Top View of entire completed

SP-600 Receivr