Homemade Arc Welder

Old Microwave Oven parts put to good use

Take me Home!Projects Lawnmower Repair Forge

During some night of July or August 2012, a thunderstorm rolled through. The lights flickered and at that time fried the control board in our microwave oven. The oven was now useless without any way to control it, so we bough a new one. But what could I do with the old microwave?

I discovered this project and several other similar ones. It was time for me to build a welder, that way I could build further Cool Stuff.

The welder consists of two microwave oven transformers (MOT's) with the original secondary windings removed and replaced by about 20 turns of 10 gauge copper strand wire. Now the MOT's have been made into voltage step-down transformers, and can supply a decent amount of current for welding.

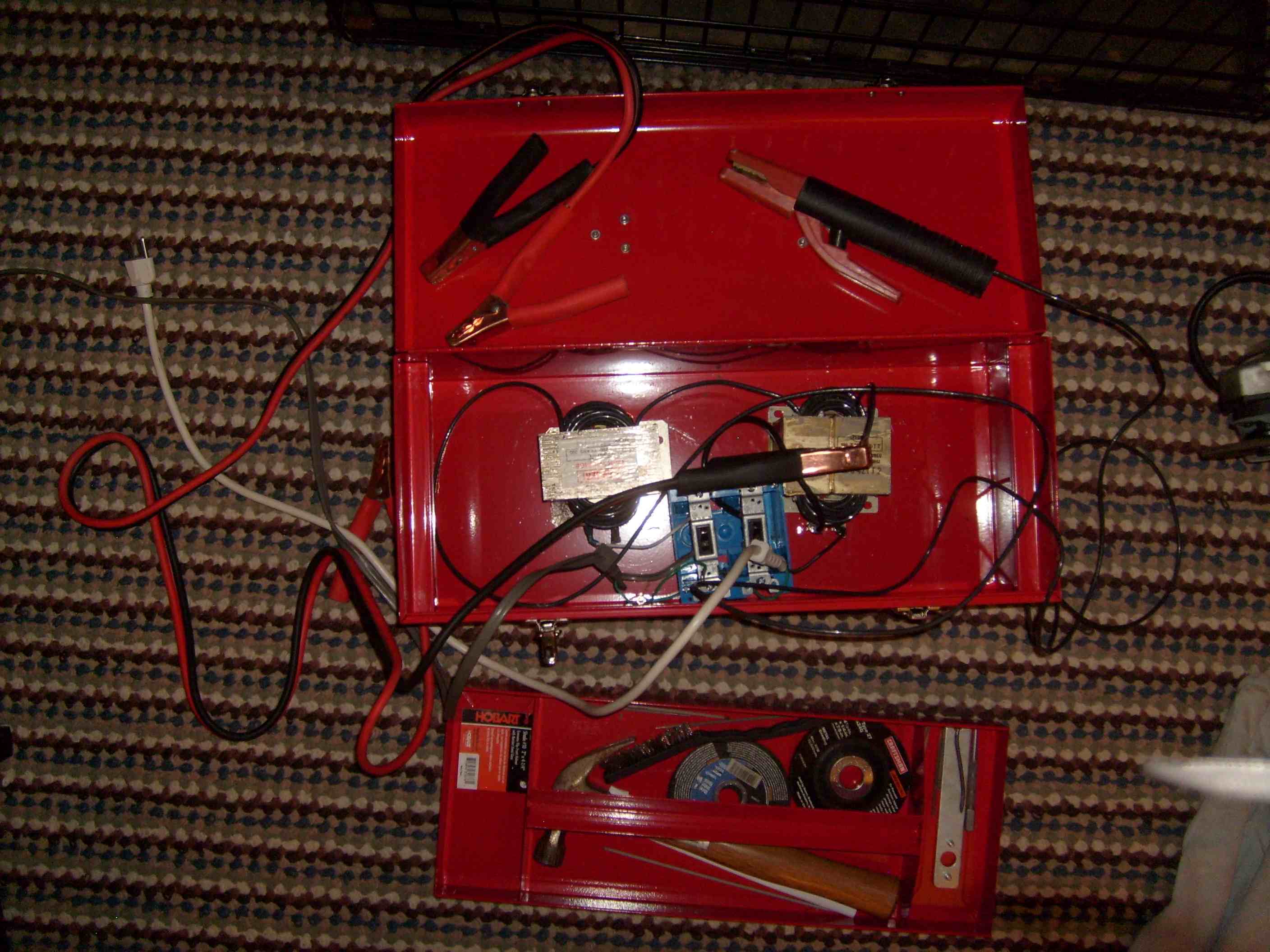

I decided to put my welder in a metal toolbox to make it easier to carry around. The tool tray is also nice for

storing electrodes, gloves, and other such welding accessories. I also added a couple of light switches to make it

easy to switch off and on. The stinger clamp is one I got from Harbor Freight for about $10.

You can see my setup in the image:

Here are a couple of nails I welded to a used brake disc while I was first learning to weld. It works! Maybe not well,

but I hope practice will improve the welds. The welder seems to use 1/16" rods very well. I've had particular success with

7014 rod from Harbor Freight.

I will, as time goes on, probably improve the transformer mounts and add a cooling fan. I have read that adding

capacitance changes the reactance of the welder such that you get a more efficient weld.

Some Projects:

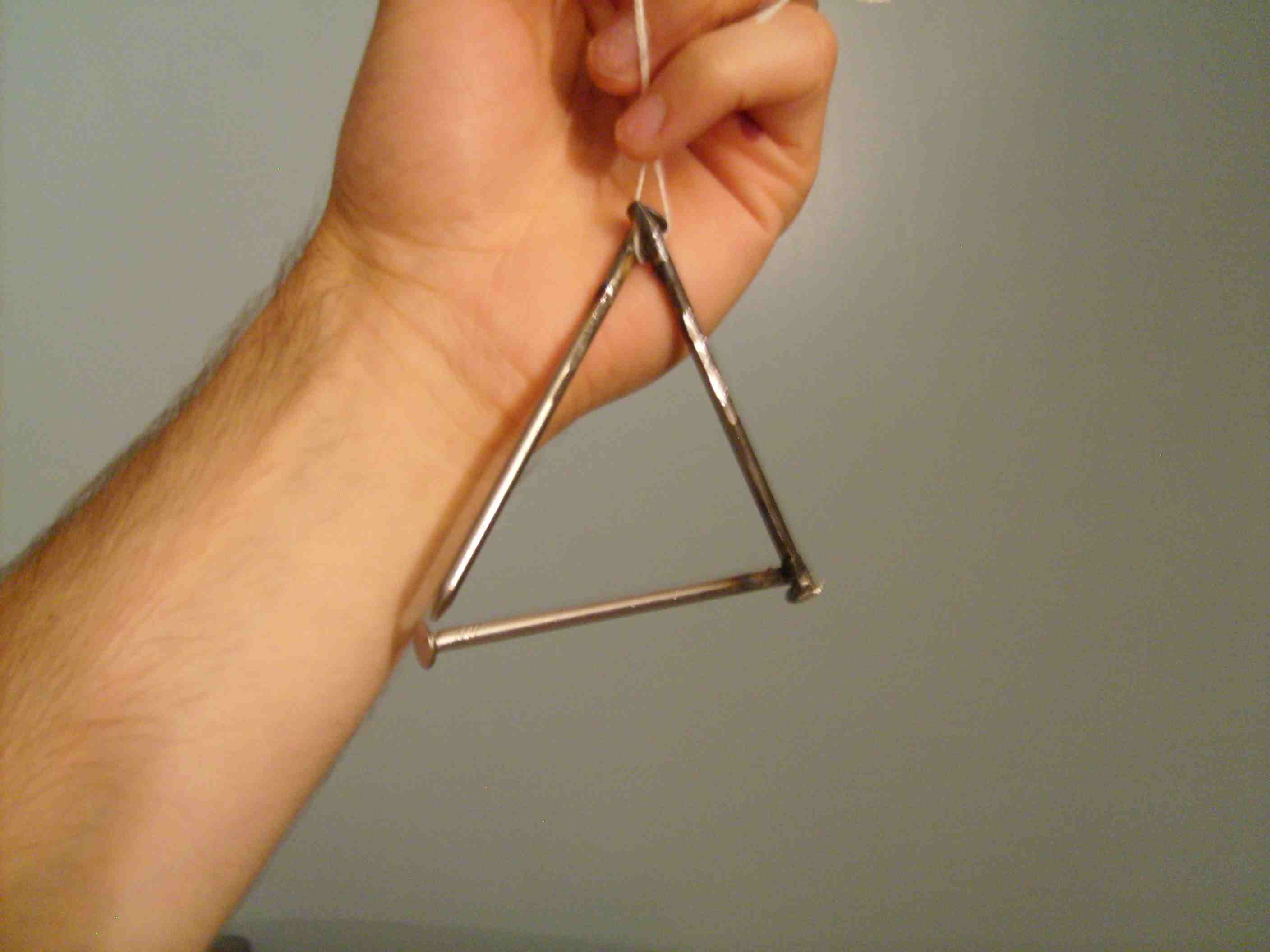

A simple dinner triangle.

My lawnmower handle had broken from lots of use. Prior to having a welder and the minimal

skill necessary to use the welder, it was held together by duct tape and a wooden stake:

So I decided to weld it back together. But the handle is tubed sheet metal, so it is on

the thin side of what can be acceptably welded without melting away completely. To counteract

that, I used a nail as filler material. The result is OK. It holds together, perhaps in an

ugly way, that's for sure.

Homemade Forge

I've had it in my mind that I can build a forge, now that I'm able to arc-weld.

This site gave me the inspiration

to do so. An old tirerim and some leftover fenceposts provided ample material to make the firebowl

and stand.

Here is the finished firebowl and stand. I need to add a bottom and some way to pipe in the

forced induction from a blower.

Next I have added leg braces and a brake disc to serve as the bottom of the firebowl.

Written on 6/9/2013

Updated 6/23/2013

end of line