MAKE YOUR DRILL MORE "FLEXIBLE"

Here's

the tipical "stupid stupid" but very useful project:

it's nothing special;

I just needed something to work on PCB (making hole, cutting and so on)

easily;

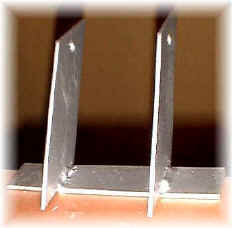

That's the idea: a simple backet where is mounted the drill and a flexible shaft

(about 150 cm long);

the bracket allows the drill to move up and down;

On the flexible shaft ther's a push-button wich switch ON-OFF the drill.

Schematic is very simple: a transformer gives 12 VAC for the relay (rectified

by a 1N4001 diode);

The relay , when the push-button is down, give 220V to the load (the drill).

The "inverse" diode on the relay's coil avoid any arching, while the

220MicroF capacitor levels the rectified current and give a short delay to the

relay (to avoid continous ON-OFF of the drill).

That's all, see pictures for more info

.

Costs:

- drill: sure you still have it;

-flexible

shaft: 15-25 euro;

-ABS box, trasformer, relay ecc.: all surplus.

-

bracket: home-made.

73 de iz7ath, Talino Tribuzio