A button press on [CCW] or

[CW] makes the rotor move 22.5 degrees either ccw or cw.

I will allow a rotation of 360° minus 22.5°, 15 steps on

each side from N. A short press on the [CW] button wil move

the Rotor 22.5° clockwise and then stop. The first LED cw

from N goes ON. Continuously pressing the [CW] button keeps

the Rotor moving and the LED's indicate the movement

in 22.5° steps. After a movement of 270° cw from N over E

and S to W, the Rotor is moving out of the "safe sector". It

can still be moved further on to N - 1 step, but the

LED color turns from blue to bright red. The last

allowed position 22.5°, one LED left and right of N, gives a

clear indication in what direction the rotor has to be be

moved to get in the safe sector. From here on further cw

movement is blocked.

And vice versa.

Have a look at this short video:

https://youtu.be/9pHU1JZAdzU

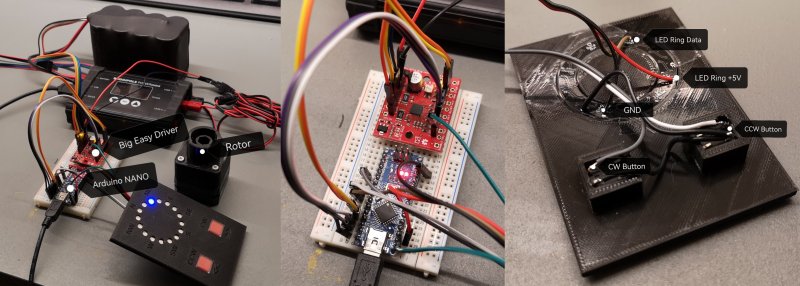

The hardware is extremely simple:

On the rotor side

- 1

NEMA 17 42x42x34 or 42x42x40 Stepper Motor

- 1

Adapter like the one David is using for his DC-Rotor,

modified for the stepper motor

On the controller side

- 1

Arduino NANO or UNO

- 1 Big

Easy Driver

- 1

NEOPIXEL 16 LED Ring

- 2 Push

Buttons

Rotor and controller are connected with a 4 core cable

Power supply

- 12 to15

V DC for the rotor, same as for TRX

- 5 V DC

for the Arduino

all available from the PowerMini, but I am using a positive

voltage regulator xx7805 1.5A to power the Arduino (Vin)

from the 12 V line.

Simple pin to pin wiring between the components:

- 5 wires

between Arduino and face plate with LED ring and

buttons

- 6 wires

between Arduino and Big Easy Driver

- 4 wires

between Big Easy Driver and rotor

- 12V to

Big Easy Driver

- 5V to

Arduino

Simple wiring

The wiring is clearly documented in my

Arduino

Sketch.

For more information about the

<Adafruit_NeoPixel.h> library see:

https://github.com/adafruit/Adafruit_NeoPixel

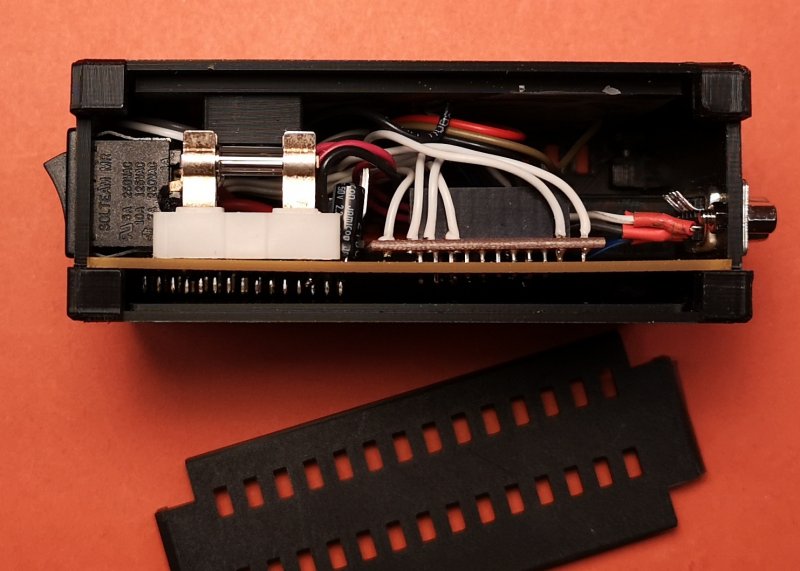

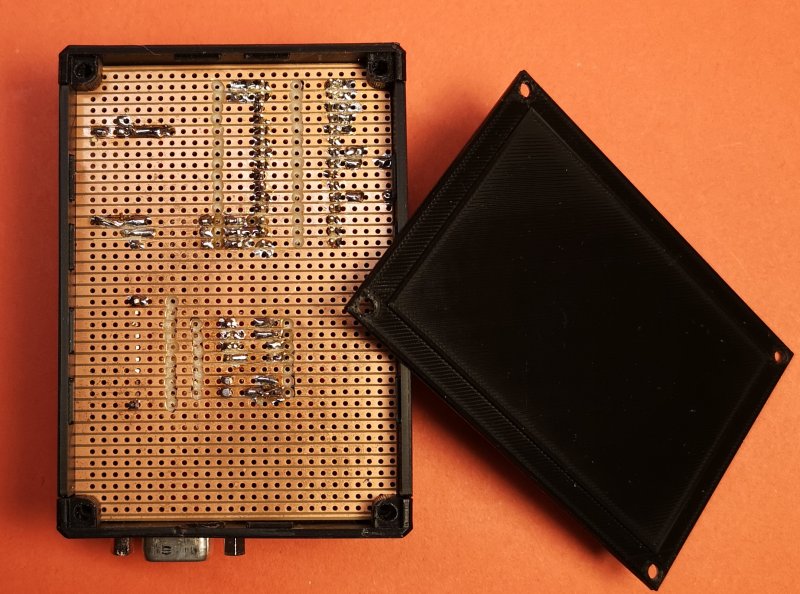

The controller case

Controller Case

I made a 3-D printed case for my controller, a remix

of the

(tr)uSDX

case.

Case, (tr)uSDX style

Inside viev

Side view, showing position of the breadboard

Bottom view

Unfortunately,

all the Neopixle Rings have (slightltly) different

dimensions, the same applies to the push buttons

and other parts you find in your junk box. So the

STL-Files might not fit your parts and you might

have to remix the STL's.

Here you can download

the STL.Files of the Case

If you are familiar with

OpenScad, pse. contact me for the SCAD.Files.

1st Results of Field Test

There is not much to tell. The setup was working as

expected. After 2 1/2

hours of operating the stepper rotor did not loose one

step!

The resolution of 22.5° is absolutely sufficient.

This video shows the movement of the rotor: https://youtu.be/-c7IjqDggso

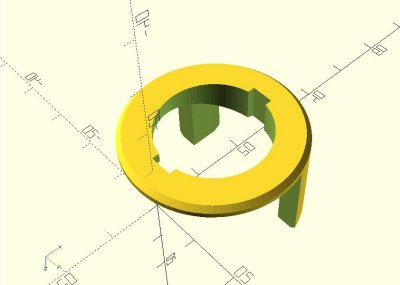

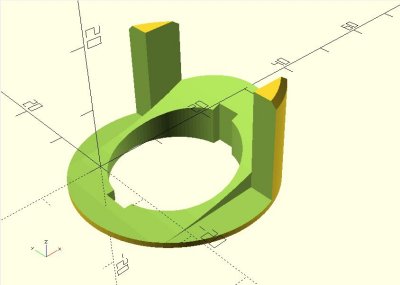

The No-Loose-Adapter

The No-Loose-Adapter fills the gap between the hub and the

Rotor

The No-Loose-Adapter is a gadget I have been using almost

since I got my first MASTWERKS mast five years ago.

I did not like the loose feeling of the crank handle so

I made a 3D-prited part to fill the gap between the hub

and the crank handle. I have my No-Loose-Adapter

permanently attached to the hub. It is mandatory for a

firm fit of the rotor.

Here you can download

the STL-File.