The GM0ONX Rotator Controller

My rotator is an very old CDE (Hygain) Ham IV rotator with about 30 plus years of service and is still going well. The controller was one the old style with a large centre meter and a bar that you moved left or right to control the direction of rotation. It was effective but looked out of place in a modern radio shack looking like something more at home in a 1960's physics class.

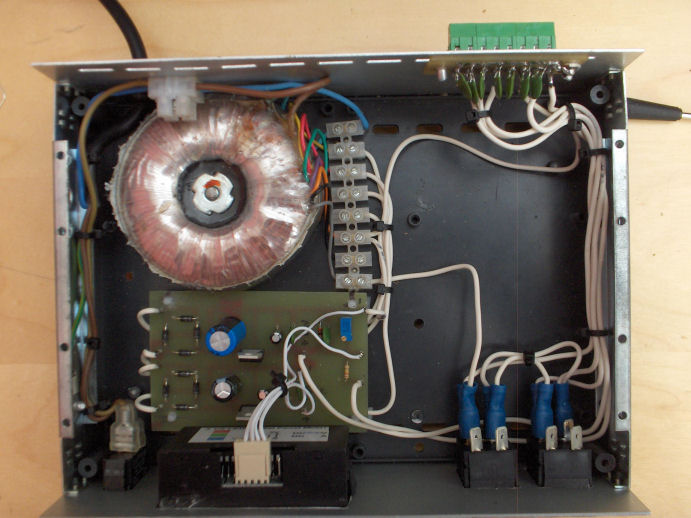

The replacement controller is actually a very simple affair and applied a 5V regulated voltage across the variable resistor on in the Ham IV which is used to indicate direction. The was then divided down via a couple of resistors to give a voltage reading of 0.036V at 360 degrees. As the variable resistor in the rotator is linear it gives a fairly accurate indication of direction when used with a 199mV meter. As the Wiper arm of Ham IV is connected to earth it is important that both power supply are not connected to earth to correctly measure the wiper arm voltage (0 to 5V for 0 to 360 degrees).

Most digital voltmeters modules require that power supply feeding the is totally independent from the supply it is measuring. Failure to comply with this requirement can cause destruction of the DVM module.

|

|

|

|

|

I used a toroidal

transformer which provided two 100mA outputs (8v and 10v) in addition to

a 15-0-15V (30V) output at 3A bought from eBay as a 'pull' from a piece

of equipment but separate transformers are fine. Do not be tempted to

use a transformer it a common centre tap for the measuring circuit, they

must be totally separate. The original transformer provided a 28V 3A supply AC supply to power the motor and the brake but 30V AC is close enough for the purpose once you take into account the voltdrop on the cable to the tower. The original transformer is not rated for a 100% duty cycle and nether is my replacement but I have not noticed any overheating issues in normal use. The 30V motor supply is applied via a couple of double pole momentary switches which have their wiring 'interlinked' so that when you press the switch for one direction it automatically open circuits the supply to the other motor connection. The Ham IV normally requires a 8 core cable as the starter capacitor for the rotator motor is located within the controller. This is necessary in extremely cold climates as the capacitor can fail to work in extreme cold however this is not usually a problem in the UK. I moved the capacitor from the controller to the rotator body meaning I only need 6 cores (2 off 3 core flex.) The fetching blue display used in the project was bought off eBay from Hong Kong for less than a tenner. |