California Amplifier 31732

Downconverter

Overview

Originally designed to receive terrestrial television broadcasts

in the Multipoint Microwave Distribution Service (or MMDS) these

downconverters exhibit enough gain and local oscillator stability

to serve as a receive converter in the Amateur allocation at

13cm, once modified. Modification is as basic or complex as

situations allow in the owner's shack. If a wideband multimode

scanner is available (for example, the Yupiteru MVT-7100 and

others) there is no need to perform any modification more complex

than the in-built bandpass filter. Conversely, if only a 144MHz

multimode receiver is available, then a crystal change (more

information in subsequent parts of this document) will be

necessary, in addition to retuning the bandpass filter.

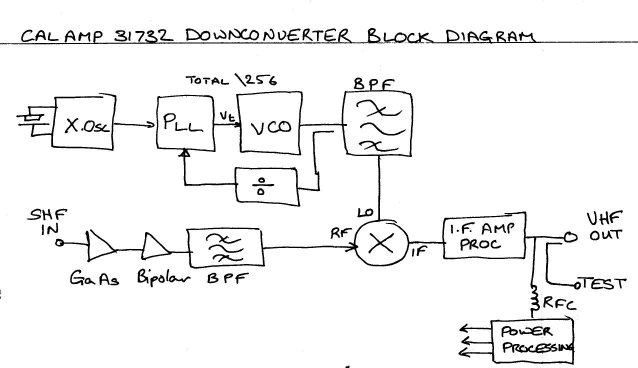

Inside the 31732

What first appears to be an intimidatingly complex piece of

equipment, is in essence the larger portion of a superhetorodyne

receiver in itself. The block diagram is shown in figure 1. In

order to 'block downconvert' the wanted band, the RF signal

'block' is amplified, filtered to remove the unwanted RF spectra,

and then mixed with a local oscillator source to produce a new

'block' at the Intermediate Frequency. Further amplification is

applied at this point to overcome cable losses and to restore the

overall performance.

Fig.1 Cal Amp 31732

Block Diagram

A phase locked loop Local Oscillator is used to mix down the

signals to the IF. The PLL consists of four components. A crystal

oscillator reference, a PLL chip, a VCO operating over the

appropriate range, and a prescaler to divide down the VCO output

for comparison in the PLL IC with the reference frequency. The

phase locked output of the VCO in the converter is normally

2278MHz. The whole PLL system divides this by a total of 256 to

compare with the reference crystal. Therefore, To change the PLL

frequency, we change the reference crystal.

Modification

Unconverted the units do not have sufficient sensitivity to

receive signals, except the strongest, gain being many dB's lower

at 2320 and 2400MHz than the MMDS portion. Retuning the filter,

in the case of the satellite allocation at 2400MHz is not

unnecessarily complex, and the entire filter can be slabbed with

a sheet of teflon shim to bring the filter resonance back to

2400MHz. A piece of 0.015" teflon sheet or tape is stuck

directly over all the filter resonators. This is the simplest

modification possible, and is a compromise.

In the case of retuning the filter to work at 2320MHz (the 13cm

SSB section of the band), further work is required, and in fact

the technique is equally applicable at 2400MHz, and provides

superior results to that obtained by the use of teflon shim/tape

alone. With this modification further test equipment is

desireable, as it is necessary then to provide a variable signal

at the signal frequency, and a means to monitor that signal and

peak up the filter for best response.

Using small pieces of copper or brass shim 0.001 or similar, it

is possible to move the filter right onto any frequency in the

13cm allocation, and obtain best performance. These are

individually tinned, and brought over the existing stripline

until an improvement can be obtained, whereupon they are soldered

in place, repeating the whole excercise until no further

improvement can be obtained. Many tabs and a fair amount of time

and skill is required to obtain the best results. Reference to

the appendix included with this document is advised for this

procedure - it is the author's preferred method. Working ones way

from the output side of the filter to that of the input is the

method to adopt when retuning this filter.

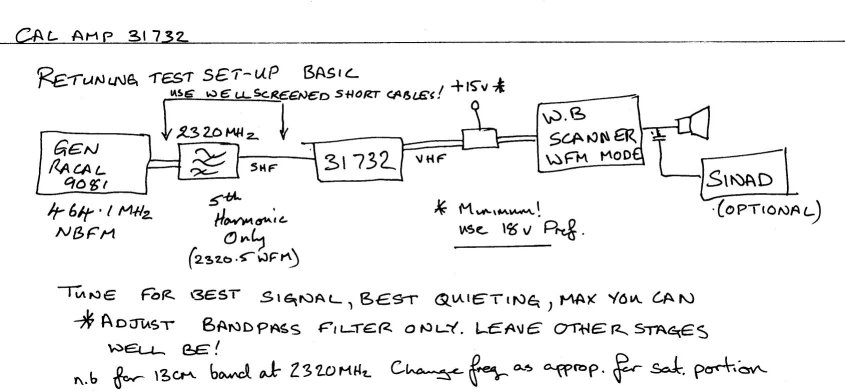

One usable scenario for retuning is illustrated in figure two

below. More sophisticated test equipment can of course be used

instead. The basic idea is merely represented here, but the

system outlined does produce good results.

Fig.2 Retuning setup

with basic equipment

Note that more exotic equipment could be used (and the author posesses this), however the equipment above gives good results, and is in the author's estimation, typical of the intermediate UHF experimenters equipment inventory.

Note that it is very important to not manually tune this filter

for the highest S meter reading, the mixing process produces not

only the wanted signal, but an image signal (which will be

noise). Tuning for best S meter reading will allow more of the

unwanted 'noise' to interfere with the wanted signal, the result

being a large reading on the signal meter, but potentially poor

performance with weak signals. Tuning the downconverter for best

quieting and signal/noise (or SINAD) will improve matters

considerably. Access to a SINAD meter is not so important if you

have good ears, and can tell the difference in quieting. It is

not necessary to adhere to this when 'cladding' the filter with

PTFE, as you will have to accept the results obtained by this

method. The author is very lucky to have good hearing, and can

equal the results obtained with a SINAD meter. An oscilloscope

connected to the receiver's output will aid manual retuning to

some extent by examining the roughness of the modulation. Results

of retuning by hand with the author's preferred method exceed

46dB of image rejection at 2401MHz with a 145MHz IF. This is

quite adequate.

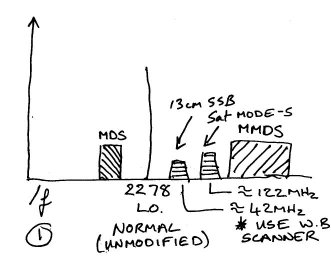

As was said earlier, if a multimode wideband scanner is

available, or a receiver capable of receiving all-mode at 42MHz

or 122MHz is available, then the local oscillator reference

crystal will not need to be changed. Once the filter is tuned,

the signals from either the 13cm SSB or satellite portions will

be easily received.

Fig.3 The local

oscillator at 2278MHz can be used without modification to receive

13cm signals

However if only a 144MHz SSB receiver is available then the local

oscillator will need changing to either 2176MHz (for 13cm SSB) or

2256MHz (for the satellite portion). A crystal is easily

obtainable from Hy-Q (now Precision Devices International) and

the frequency calculated from the function below...

Crystal Frequency = Local Oscillator

Frequency / 256 ( all freqencies in MHz)

Crystal is in an HC49/u holder, 33pF load capacity fundamental,

accuracy is 10ppm over -30 to +60 Celsius.

The crystal can be ordered from Hy-Q with the following ordering

code:

QC49 FUNDAMENTAL [xtal frequency in MHz] FG05F

And is of identical performance to the original quartz crystal

used in the unit.

A more economical alternative is from Quartslab Marketing in the UK, a set of test crystals were ordered, and found to be of identical performance to the Hy-Q units. Details from the author on request.

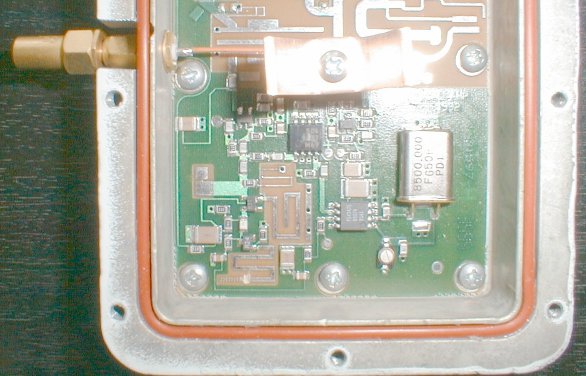

For a local oscillator of 2256MHz and 2176MHz no further

adjustment to the LO circuitry is needed., other than the crystal

change. The photographs show the authors unit, tuned at 2320MHz

with a 2176MHz local oscillator, with the transveter LO tap (see

end of this article).

The received IF will then be available at 144MHz. Once the

crystal is changed, the operating frequency can be easily

adjusted with a frequency counter by means of the trimmer

adjacent to the crystal. Remembering that if measuring the

frequency of the crystal oscillator, any error in trimming will

be multiplied by 256 at the Local Oscillator frequency.

A 1Hz resolution at 8-10MHz is desirable if measuring crystal

frequency. 10Hz at signal frequency. Several alternatives for

measuring the Local Oscillator frequency are available, and the

author posesses a Watson 3GHz counter which with a 30MM insulated

probe works most satisfactory. An EIP Microwave counter was also

used with higher precision still. Wavemeters will not be accurate

enough at the LO frequency for any more than an indication of

operation. Of course if your alignment signal is calibrated then

the signal can be netted by zero beating, or even an HF receiver

could be used to get the crystal frequency close.

When calibrating the crystal oscillator, bear in mind that there is always a little uncertainty, and that there is some 'backlash' in the adjustment due to the loop on the PLL. Shoot for 250Hz accuracy on setting as the trimmer is 'all or nothing' - I can get 70Hz, but only after compensating adjustments, and around 10 minutes work; be prepared to put in some time on these, and allow at least an hour to let things stabilise before any adjustment. That goes for your frequency counter too - they aren't 'WWV on demand' to coin a phrase. The room or workshop in which you perform the adjustments should be stable in temperature too, matching to your normal average ambient temperature is ideal.

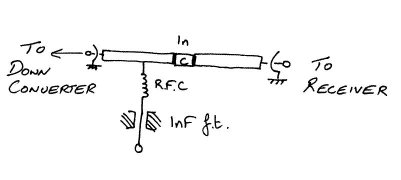

DC Injection

In the event that your receiver is incapable of supplying the

16-25V required at 1/4 A (and it is suggested that the

downconverter be run at no less than 18V) then a power inserter

will be required. Desireable characteristics are a sealed unit

that prevents leak-in of strong signals on the IF frequency from

local sources, sufficient bypassing at RF of the DC supply, and

low insertion loss. A suitable unit can be home made with nothing

more than a scrap of PCB, a sharp knife, some 1nF capacitors, and

a VHF RF Choke. Accompanying figures show a suggested layout.

There is some leeway in component values and tolerances are not

critical. A PCB will be made available if desired. It is

recommended to use SMD capacitors and good feedthroughs for best

results, however the experimenter can work with whatever

materials are closest to hand. Keep all lead and line lengths

short.

Since this document was prepared, as an

excercise, a DC inserter was fabricated from a small diecast box,

with an F type socket on one side, and a BNC flange mounted

socket on the other. Power was brought in via a panel mount DC

jack. A 1nF AVX radial multilayer ceramic capacitor (chip cap

with leads in an epoxy blob) was used to span the two RF

connectors, and a VHF RFC was taken to the DC jack. This

arrangement works extremely well. The SMD alternative is still

favoured, but for robustness the diecast box definitely has the

edge

Fig.4 DC Injection to supply the

downconverter, striplines are approx 0.1" wide on a small

piece of D/S PCB material

Transverter

It is indeed possible to use this downconverter as a basis for a

13cm transverter, and as such offers good performance at an

advantageous price. A tap from the local oscillator can be

obtained by insertion of a 30mm probe situated above the first

local oscillator bandpass filter's stripline, and spaced

equidistant from the top surface of the pcb and the top of the

lower casing. It is awkward to mount a suitable connector in such

a confined space, however an SMC connector will fit into the

available space easily. Some removal of the diecast casting on

the exterior is required, caution being required not to overdo

the 'milling' or getting metallic dust inside on the surface of

the printed circuit board.

Positioning of this probe tap yielded some +4.5dBm of LO power as

measured on the author's HP432A power meter. This was ample to

drive a balanced mixer to produce 2320MHz with milliwatts of

144MHz drive. There are several designs for 13cm transmit mixers,

however the author has developed a suitable transmit mixer with

parts salvaged from an Ionica subscriber unit, with a low level

amplifier capable of driving a PA to whichever power level as

necessary. A PCB layout (G0ORY-005) is also available, and can be

fabricated with 'press'n'peel'. however the design is still in

the beta stage at present, but the design is available on

request.

The transmit mixer is online here - http://www.qsl.net/g0ory/2.3g/005/005.html

Portable operation

A suitable design by Peter G3PHO is included with these papers

and represents a useful portable DC source for the voltages

required by the downconverter. Acknowledgement to Peter and his

excellent Microwave Newsletter are given herein. Peter has much

information available at his website - The world above 1000MHz - http://www.qsl.net/g3pho.

A.M G0ORY QTHR 07.2002 [email protected]

Appendix - retuning the stripline filter

on the 31732 downconverter

Using strips of thin copper (.001" brass should work too

K&S metals shim kit from hobby stores) I first cut the foil

into strips more or less the same width as the filter lines. Then

clean both sides thoroughly with a fibreglass pencil until it's

really really clean, and tin with the least amount of solder

possible. Run the iron up and down the length of the stip whilst

holding it by the end in a pair of tweezers, and first let

gravity do the work and let excess solder run to the bottom. A

sharp flick of the tweezers whilst the tin is molten shakes off

the bulk of the excess. Second, run the iron up and down the

strip once again, and flick the excess off, so there is as little

solder as possible on the strip. get some cotton buds, and some

nail varnish remover - cheaper stuff is better as it contains

less oils, a large bottle costs just over £1 and lasts years (or

pure acetone, ethanone flux off, isopropanol - sold as 'head

cleaner' 1.1.1.Trichloroethane - sold as 'tipp-ex thinners' ),

soaking a bud in the mixture and then cleaning thoroughly all

traces of flux and residue from the strip - you'll be surprised

just how much comes off! Whilst at the chemists with this little

shopping spree, get some wooden toothpicks too, a small box will

last years.

Open up the unit, making note of the general layout of the

filter. The filter consists of alternate 'u' and 'n' elements -

referred collectively as a 'hairpin filter' No board traces need

to be cut, which is a godsend because the modification is at

least reversible. If you make a mistake, remove the wrong piece

and start again.

Remember, use a good earthed soldering iron, and earth the work,

preferably by strapping the negative of the power supply to

earth. A good earth arrangement is essential to save any damage

caused by static. It's just plain good sense too. Remember also

that you should power up the converter only when checking the

results of your efforts. Always power down when you're soldering

- it's easy to harm it if you don't! A rigid discipline and a

systematic approach is a must. Also only work on the equipment

when you are well and able to do so, and not when tired, under

the influence, or agitated. A clean soldering technique is

advisable. Regularly clean the iron before each soldering

operation, and use a minimum of solder. Dross, contaminated flux

residues and bad tinning will cost you dearly in the long term,

with intermittent losses of sensitivity, thermal intermittents,

and other nasties.

Note that on some units there are dabs of solder left at the

extremes of the hairpin elements to effect tuning. These can be

removed with desolder braid (Chemtronics Chem-Wik Like is

recommended, ordinary desolder braid doesn't mop as well). Then

clean the board with a cotton bud again to remove flux, then use

the dry end (the one you didn't dip in the stuff) to dry off the

board. Desolder braid is a handy thing to have. Don't even

contemplace using a solder sucker - the percussive blows from

these do more harm than good, and in any case it's ineffective.

Also, when the techs at cal-amp tuned the board up for MDS/MMDS

use, they used sharp knives to cut traces on the board. They were

a bit heavy handed, and sometimes gouged lumps of dielectric out

of the board, leaving a mixture of dead trace and fibreglass

sticking up on the board. Using a small sharp scalpel or fine

knife gently lever and scrape away this mess, and try not to make

any more damage than is already there. This helps makes a cleaner

job. If you get dust or bits inside the unit that just plain

won't come out, use a photo puffer brush, clean blusher brush

bought purely for this job (not one smothered in makeup!), or

canned air to shift it.

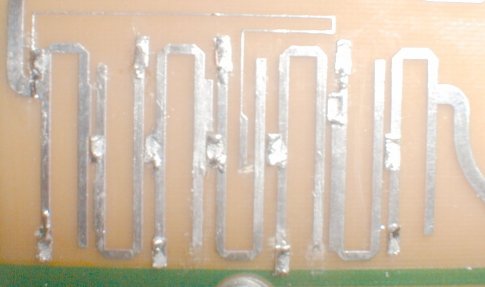

Get both of my photographs of a modified unit to hand and study

them well. This gives you the insight into the attack points for

retuning.

Right, you're connected up, with your receiver monitoring for the

correct conversion, the signal generator switched right down to a

safe level (lowest possible to start), and the unit powered up

without its lid in front of you. Let's begin.

Advance the signal generator, until noise is detected on the

receiver. Use only as much signal as is necessary to get a

noisy-ish signal out of the unit. I'm going to refer to using the

noise and level on a wideband FM signal (50KHz) here to do my

alignment, but if you have a clean enough generator, you can go

SSB straight away, and listen to the loudness and signal reading.

You can tune the filter now, try the unit out, and see if you

need to change the local oscillator crystal. The IF amplifier is

broad enough to work okay at 42MHz for 13cm SSB, and at 122MHz

for 2.4GHz. At 144MHz IF's for 13cms it's still very good.

Looking at the first resonator, where the stripline couples into

it, you'll notice some small traces arranged in a square. Moisten

the sharp end of the toothpick, and pick up a piece of that

tinned strip around 3/16" long. Put the strip in the area

indicated and move it around, watching for an increase in signal

coming out. You'll notice a useful increase. When you get the

largest increase you can. Remove power to the downconverter, hold

the toothpick fast, anchoring the tab, and just touch the

soldering iron to the strip end. Solder will flow easily because

everything is clean. It's soon soldered, so don't spend all day

with the iron on the strip! Wait for it to cool and remove the

toothpick. Turn the power back on, and check that the increase is

about or better than the increase you had.

Take another piece, same length (cut several and have them laid

out ready), and waft in direct contact over the first piece you

applied. If you get more signal, do the same as before and solder

the new piece in. If not, move onto the next stage.

On the resonators, it's best to lengthen only one side of the

resonator hairpins at once. Find with the toothpick arrangement,

which I'm sure you're familiar with by now which side gives most

signal and stick with it. Sometimes the length of strip will be

at an extreme, others will hardly extend the original trace at

all. This doesn't matter. Each time remove power, solder in, and

power up again to check. You should now be reducing the signal

generator after each piece is soldered in to a noisy or weak

signal to ensure that you find the sweet spot that gives most

increase.

When one extreme is done on these hairpins, it's always the

opposite extreme on the next hairpin which provide the best

increases. The pattern snakes across the entire filter in this

way. After you've worked on the filter all the way from the input

side to the mixer you're about done. Note the decrease in the

level of signal generator input required now from what you

started with. This corresponds to all that lost gain!

Wafting these little tuning strips around the second stage tuning

after the first GaAsFET amplifier didn't give any improvement in

signal, leave well alone here - in particular don't adjust the

wire loop on the input to the GaAsFET in any way, leave well be!

This decides the noise figure which is already good in this case.

Only re-adjust with a noise figure meter, if you are fortunate

enough to have access to one.

To get the best out of the filter at 2.4GHz is easy. When you're

done, you can try wafting the tuning pieces over the other traces

around the filter, like the notch elements to see if you can get

any more improvements, or over the entire filter hairpins again

to see if there's anywhere you've missed. Stop when you can't

find anywhere to improve. It gets silly and too time consuming

after this.

I went for absolute max on mine, and started looking at the

coupling between resonators and the width of tracks. I managed to

claw back an extra 10dB+ of sensitivity compared to what it would

normally be at 2.3GHz with the filter mod I've described above.

If you're sure of yourself and patient, you can follow my work

and get the maximum out of the filter. With the normal mods, I

was able to receive my local 2.3GHz beacon (only running a few

watts erp out of its zero gain antenna at over 10 miles away) at

my shielded QTH in the workshop at around S5 on a 'tin can

(circular WG) antenna - many reflections could be received. After

further work, it was much stronger still, and easily received

with 30mm of bare wire inserted into the N socket alone, down in

my workshop in an extremely unfavourable location for reception,

QED.

Image rejection (FLO-FIF) >=46dB with this method, more than

adequate.

Fig.1a A retuned

downconverter hairpin filter using the author's method, for

2320MHz

Fig.2a The 'transverter tap', showing

the LO crystal for 2176MHz and the tap probe (terminator

attached)

Further massaging of the noise figure on the first stage could be performed with the aid of a PANFI, or G4COM alignment aid. In the author's and several other's experience however, the overall performance is more than adequate. If you have the test gear, it is a worthwhile persuit. The author finds now that once retuned, CW performance at 2401MHz is almost 6dB improved on the original CW performance at 2500MHz, which is very encouraging, and units exhibit >=46dB image rejection at 2401MHz with a 145MHz IF. This was after a recent test with both a levelled CW source and spectrum analyser.

A.M G0ORY. First written July 2001, Authored HTML August 2002

For enquiries or clarifiication please email me

at [email protected]

Back to the microwave

radio page

You are visitor number since

07/15/02