70 Mhz 4m LFA [Loop Fed

Array]

(Also 70cm LFA see bottom of page)

To begin with I think this has been my favourite, single band,

directional antenna. Not necessarily for the reasons you might

think. In terms of my favourite 70 mhz antenna of all it has to be

the Double Turnstile: some

horizontal gain in all directions (except vertical and horizontal

- it has to come from somewhere), no rotator required and

bandwidth to burn; I can see why GB3BUX does so well on 70mhz with

the same. However with the LFA I found it had more gain (albeit in

one direction) and importantly a wide bandwidth due to its full

wave loop. So it all depends what you need I guess. I like the

structural integrity of the LFA also. My thanks go to G0KSC for providing

the design and

allowing use for amateur non-commercial puposes. What follows is

simply my interpretation of another person's inspired idea. It

works. Interestingly I also scaled the same antenna for 70cm

without using any computer, and it worked fine too - yes 3

elements is not very much for 70cm, but it is compact.

The basic construction idea.

Waste not want not. I had a Double Turnstile which I constructed

and used for a couple of years. It was solid in performance. But,

you know how it goes, I decided a little more gain would be nice

to the South-East, as I have a good take off in that direction...

and I had not built an antenna for a while.. there was a buzz

about the LFA...

I reckoned I had all the materials so it should not cost me very

much. So I got to work. First I dismantled the Double Turnstile.

It was constructed from 1.25" tube and four 70mhz dipoles. The

tube was long enough to form the boom for a 3 element LFA and the

dipoles had enough aluminium (more or less) to form the Reflector,

Director and Loop of an LFA. I have always been a big fan of

folded dipoles in Yagi design. Very stable, mechanically strong

and simple self-matching design. So when I saw the photographs of

LFA it reminded me of an old Japanese folded dipole Yagi which I

still have - Maspro

10 element 2m yagi. As well as many old school UHF TV

Antenna driven elements made from flattened aluminium. In both of

these it was the mechanical strength I liked.

Note the horizontal (in plane) folded dipole

In the Maspro (bought in 1995) the dipole was in the horizontal

plane and (I always thought) stronger and less liable to wind load

than the traditional folded dipole. Of course the LFA is based

around a rectangular loop, but I thought it had similar benefits.

I have other yagis which match with gamma/delta or whatever, but I

always find these matching systems the weak point of the antenna.

Water and wind will find a way to cause issues over time. The coax

of the LFA is fixed directly to the element which is easy to seal.

Win/win. If the antenna is any good that is - which it is! This

page is based upon my notes seen below. I made these after taking

the antenna down as I cannot find the original dimensions:

The measurements.

I had some problem in tracking these down. I read all of the

information on the website which talks of tolerances of a mm etc.

This put me off a little to begin with. Here was I with only scrap

materials. It needn't have. The finished antenna (once tuned - see

below) worked exceptionally well. Perhaps (I do not know) there

could be further gain with more precision and better quality of

materials, whatever, it out performed my 3 element commercial yagi

even so. Now the measurements below are those as I found on the

antenna when I took it down - for a further antenna test (see

DK7ZB below).

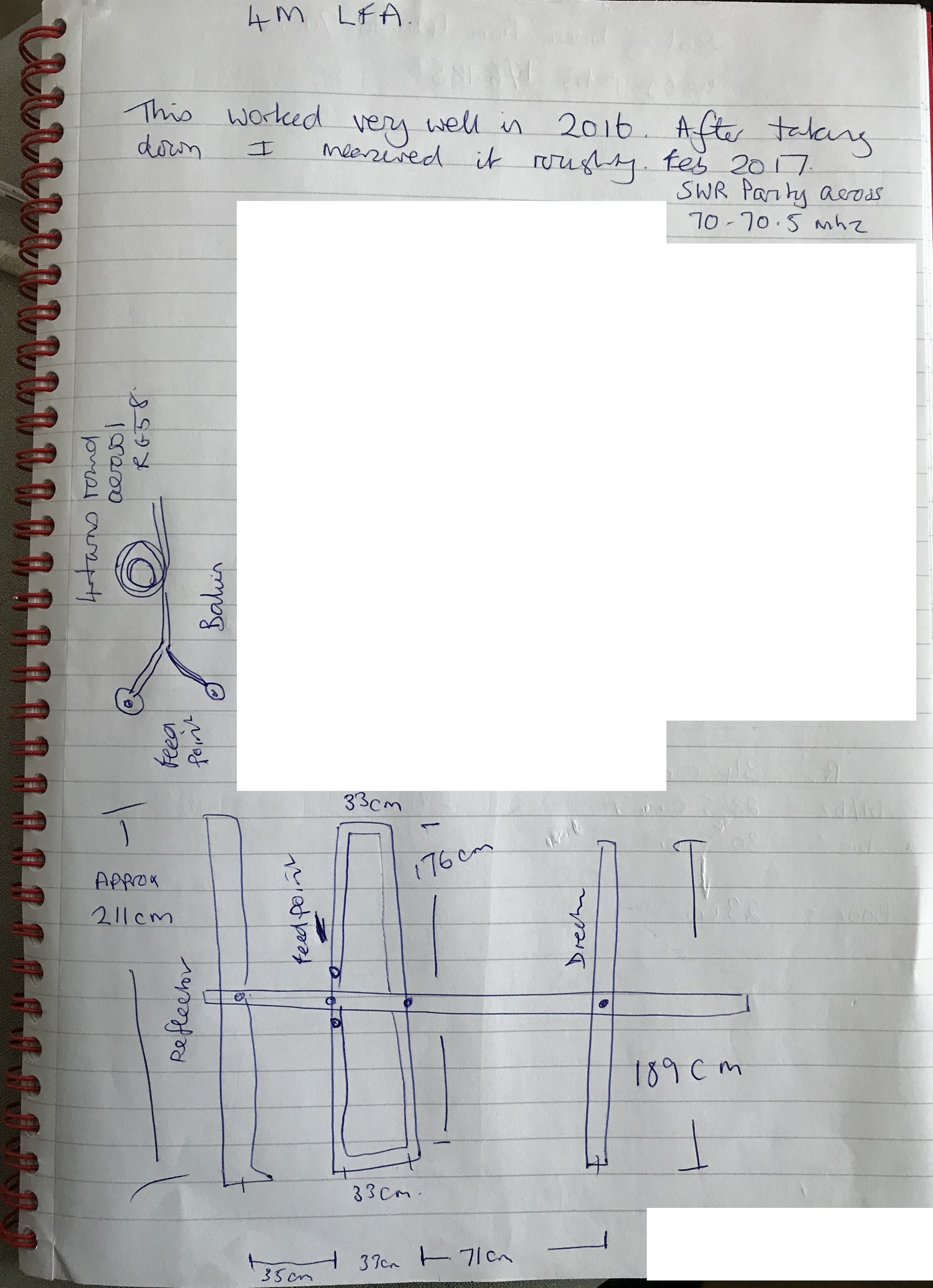

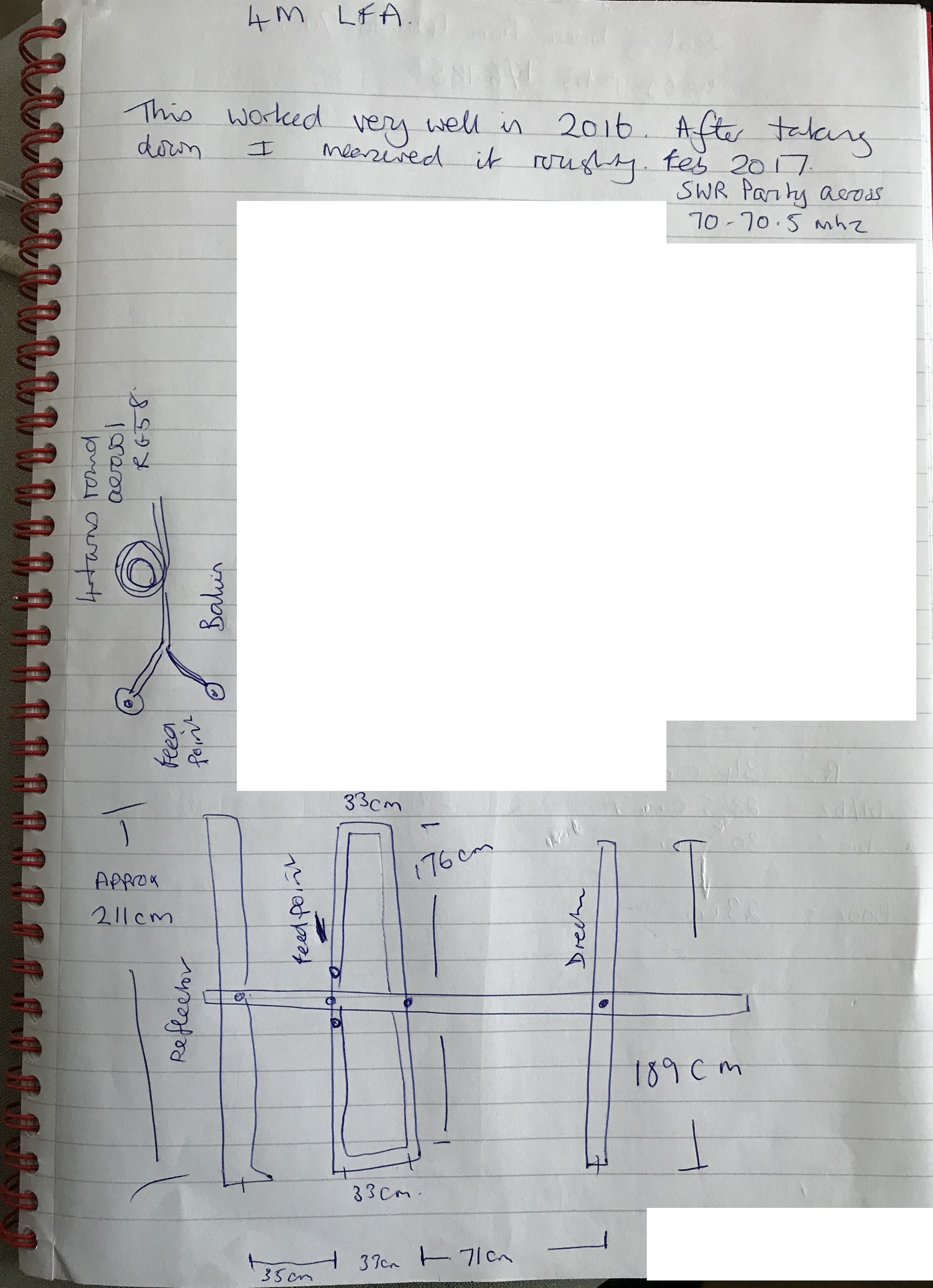

Reflector 211cm

Director 189 cm

Driven 'loop' is: 176cm across by 33cm centre wide. (I had this

way too wide to begin with and the SWR was very flat at 2:1) Later

when I made it smaller the SWR achieved virtual 1:1. It was my eye

expecting the traditional Reflector/Driven/Director to fall down

in width gradually. The width of the driven loop is less than the

director, as can be seen in the photgraph below. 176cm worked very

well.

I will add a diagram below in time...

Construction

This is where a centre line along the full length of the boom is

worthwhile getting correct. You do not want the elements as they

attach to the boom to be out of plane with each other - doubtless

why commercial versions use square boom. I find it very worthwhile

to scribe/mark a line on the top and the bottom of the boom for

the full length so that when I drill through for the dipole

centres (I used 4 of these, more later) I drill from the centre

line at the top and emerge out from the centre line below. This

keeps each dipole centre square to the boom and in the same plane

as the others.

I used the following dimensions: 35 cm from the centre of the

reflector to the centre of the feed point dipole centre. 33 cm to

the next dipole centre (which makes up the parallel section of the

loop). 71cm to the director dipole centre.

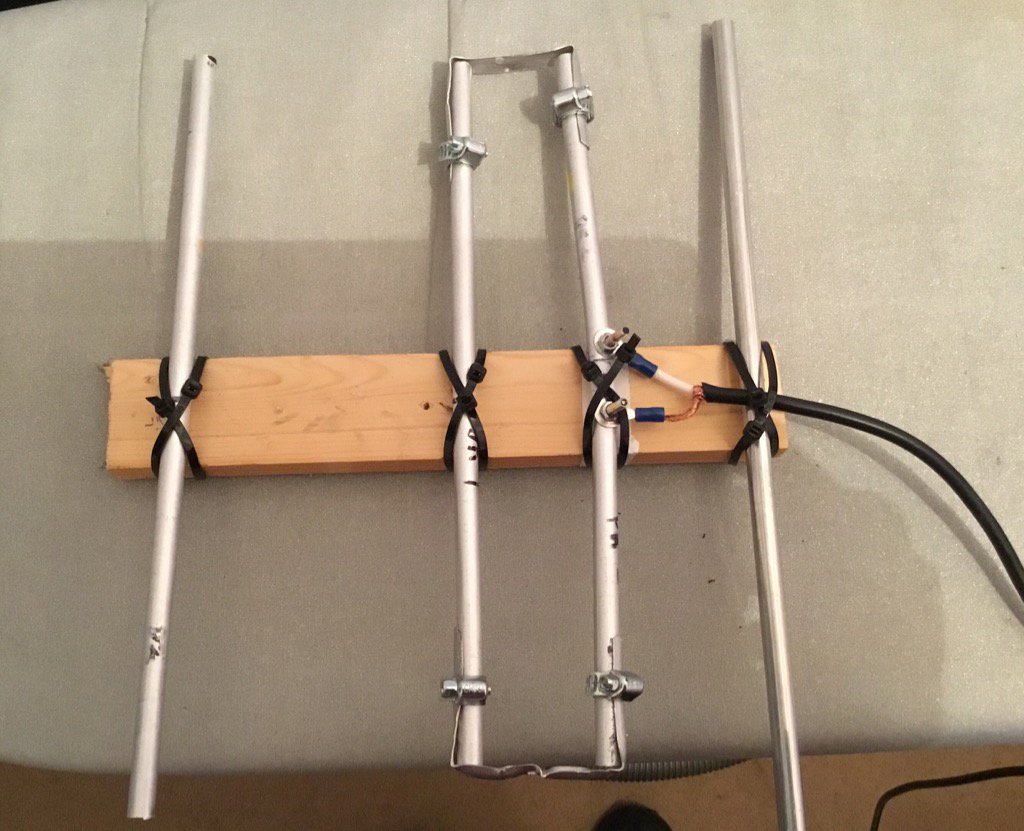

The method employed was to drill through the boom. Attach dipole

centres at four points. Only one of these was actually used for

coax (via a coaxial coil balun) at the feedpoint of the driven

element. The other 3 were simply bridged internally, using

insulated wire as thick as would fit the dipole centre terminals.

Once the half elements are attached the short makes them one

single element, isolated from the boom. The use of the same dipole

centre throughout keeps all of the elements the same distance from

the boom.

The loop section was achieved with smaller diameter aluminium at

the ends which slide inside the two loop elements to create the

rectangle - trombone style. These slide in and out also to adjust

SWR and clamp into postion. In my case a width of 176cm appeared

optimum. The dipole centre nearest the reflector is the coax

feedpoint, the other is bridged internally as above.

Balun.

The balun is ths simplest part of the whole design. I attached

eyes to the end of the feed coax. These fitted inside the

feedpoint dipole centre and were bolted into place withing a

dipole centre, then sealed by the dipole centre cap (along with

plenty of self-amalgamating

tape 25mm wide, worth its weight in gold for any antenna

builder, as well as liquid

tape on the inner screws inside of the dipole centre). The

coax behind this I wound four times around a standard aerosol can

then secured with cable ties (zip ties) and removed the can

leaving a loop in the coax which I fixed (cable ties again) to the

boom. The farther end of the coax went to the shack. After tuning

the coax was attached to the mast with cable ties. No joints, no

chance of leaks - this is why I love the LFA.

See balun on top

SWR

As stated above at first I had the loop way too wide. I set it by

eye to look like the classic yagi 'Xmas tree' profile. This is

wrong. I eventually found the SWR was great at about 60mhz! It was

then I realised my mistake and slid the loop ends further in until

1:1 (as far as the mass of the needle of my SWR meter was

concerned anyway) was achieved. This antenna was up all summer and

the following winter. It worked an absolute treat and will take

whatever power you care to put through it. I only replaced it

because I had need of 6m/4m/2m and I have only one pole. This was where the DK7ZB came

in...

First Testing (Photograph)

Note the 4 dipole centre construction technique. Three of the

centres are shorted internally apart from the coax feedpoint

closest to the reflector - take care to keep these 'shorts'

isolated from the bolts which hold the diploe centre to the boom,

I just used insulated 20 amp wire. The coax coil balun is obscured

by the pole - it is simply cable tied above the boom, see above.

70CM

LFA

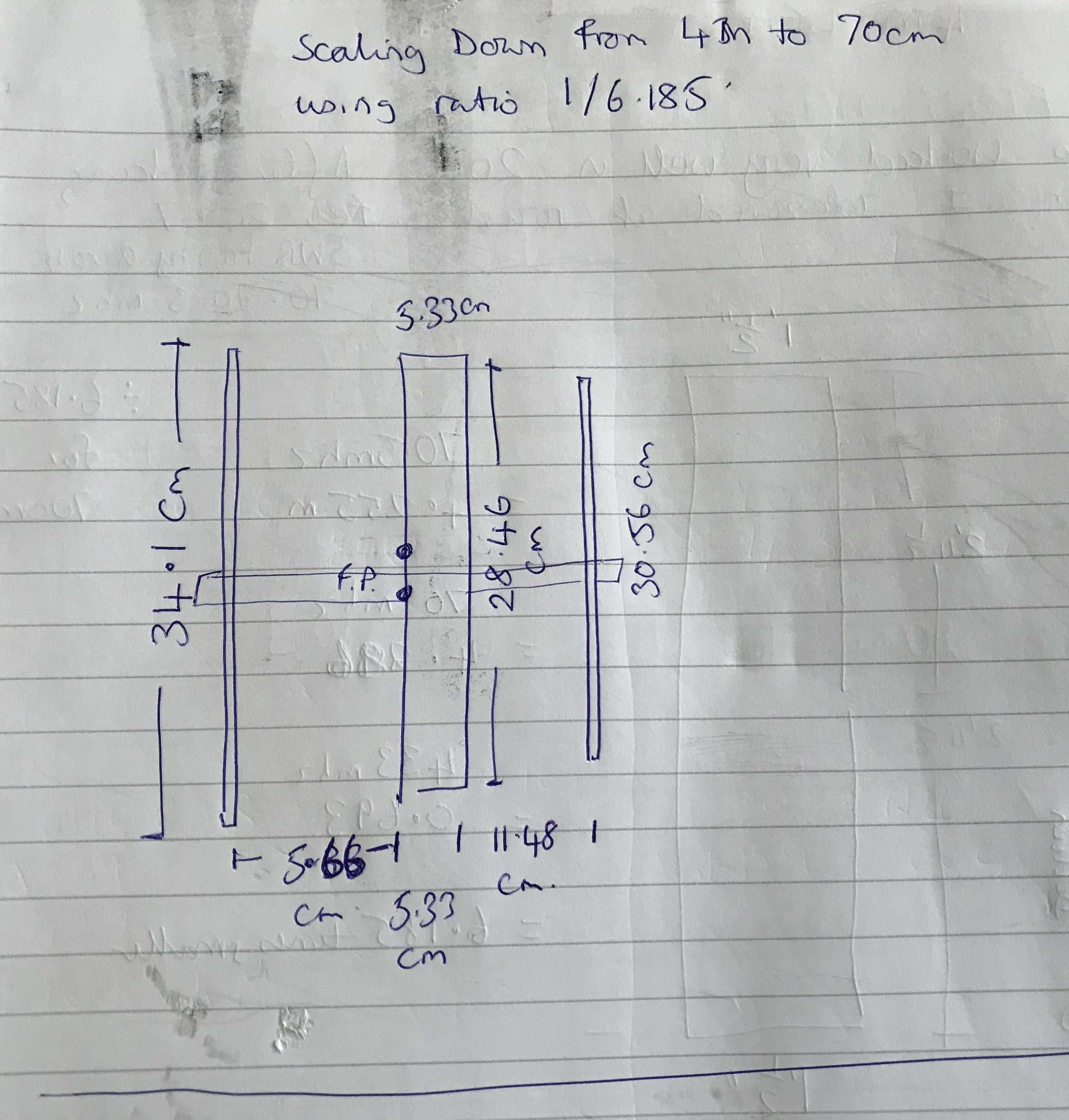

Just for fun I scaled down the antenna by 1/6.185 to produce

the antenna below - sans balun. It works. How well I cannot

tell as I only tried it indoors. However it demonstrated the

same flat SWR over a wide frequency range.

Home