|

Nitrous oxide can double the horsepower of most engines with less effort and

money being spent than any other modification. Even the "smog people"

are usually happy.

A nitrous engine can be built as a stock rebuild or it can be a dedicated

effort to maximize the total performance package. As more power is generated,

more waste heat, exhaust air flow and combustion pressures push the limits of

engine strength. Often more beef is needed in the drive train and tires.

All stock factory engines are built with a safety factor when it comes to RPM,

HP produced, cylinder pressure, engine cooling, etc. If you are only going to

use a 100 HP nitrous setup on a 300 cubic inch or larger engine, built in

factory safety factors are probably sufficient. As power output levels are

raised engine modifications are usually prudent.

The most common mistake made when using nitrous oxide injection concerns

ignition timing. A normally aspirated engine makes its best power when peak

cylinder pressures occur between 14 and 18 degrees after TDC. KB Pistons usually

require 34 degrees BTDC ignition timing at full mechanical advance to achieve

proper ATDC peak cylinder pressure. The total time from spark flash to the point

of peak pressure is typically 48 to 52 degrees. If an engine is producing 30% of

its power from nitrous, the maximum cylinder pressure will occur too close to

TDC to avoid run away detonation. If ignition does not get retarded, good-bye

horsepower and head gaskets. The key to getting max HP from a max nitrous engine

is to shift the maximum cylinder pressure event progressively further after TDC.

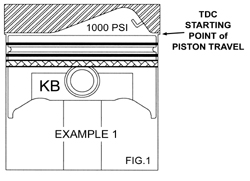

Cylinder pressure of 1000 PSI at TDC, (FIG.1) , can drop to 500 PSI with less

than 3/8" of piston travel, (FIG. 2). If you can manage to get 1000 PSI in

the same engine after the 3/8" travel, (FIG.3) , the pistons will have to

travel an additional 3/4" to lower the cylinder pressure to 500PSI,

(FIG.4). Work is defined as a force times distance. An average pressure, (750

PSI X 12-1/2 sq. in.), times distance in feet, (3/8"divided by12), equals

293 foot pounds of work.   Our second example, because it has twice the chamber volume above the piston

location, must move twice as far to lower the cylinder pressure by 1/2. Since

all the other numbers, by our own definition are the same, the force multiplied

by a distance twice that of the first example will equal twice the work done,

586 foot pounds of work. There is no free lunch in horsepower equations because

to get 1000 PSI above the piston in the second example takes twice as much fuel

and energy as the 1000 PSI in the first example. What this offsetting of the

peak pressure does is allow us to use the extra fuel mix available to a nitrous

engine without breaking and melting things. The system that allows us to

postpone maximum cylinder pressure is ignition timing retard. To a lessor extent

short rod ratios, lower compression ratios, high RPM, aluminum heads, a tight

quench, a rich fuel mixture, a small carburetor and hotter cams tend to delay

maximum cylinder pressure.

Our second example, because it has twice the chamber volume above the piston

location, must move twice as far to lower the cylinder pressure by 1/2. Since

all the other numbers, by our own definition are the same, the force multiplied

by a distance twice that of the first example will equal twice the work done,

586 foot pounds of work. There is no free lunch in horsepower equations because

to get 1000 PSI above the piston in the second example takes twice as much fuel

and energy as the 1000 PSI in the first example. What this offsetting of the

peak pressure does is allow us to use the extra fuel mix available to a nitrous

engine without breaking and melting things. The system that allows us to

postpone maximum cylinder pressure is ignition timing retard. To a lessor extent

short rod ratios, lower compression ratios, high RPM, aluminum heads, a tight

quench, a rich fuel mixture, a small carburetor and hotter cams tend to delay

maximum cylinder pressure.

Understand that, in our quest to delay cylinder pressureís peak time, more

is not necessarily better. Instead, consider that the ideal cylinder pressure

would be just short of detonation pressure and this pressure would be maintained

from top dead center, and as long as possible after TDC. If timing is really

late, you wonít build enough cylinder pressure to start the car, let alone

drive it. The 1000 PSI pressure in the example is not the maximum allowable

combustion pressure but, rather, a comfortable pressure for illustration of the

work principle.

Some nitrous manufacturers recommend, "retard the timing two degrees for

each fifty horse power of nitrous". Other nitrous kits have the flame speed

artificially slowed by the intentional use of a rich fuel to nitrous ratio. The

maximum performance engine with a heavy nitrous load must achieve peak cylinder

pressure progressively further after TDC. The heavy load engine will have the

fuel and oxygen mix to make high cylinder pressures, with the combustion chamber

size being drastically increased due to the piston being on its way toward

bottom dead center. The strongest engines have less compression ratio, less

spark advance, and more nitrous.

I have tried to explain the reason for a spark retard system in a Nitrous

engine. However, many people just donít like the idea of any retard. They say,

"retard timing and exhaust heat goes up". It usually does in a stock

nonnitrous engine because lower peak cylinder pressure slows the burning. If the

timing is retarded in a non-nitrous engine, the exhaust opens before the fuel

mix is finished burning and exhaust temperatures go up. Piston temperatures

usually go down and exhaust valve temperature goes up. In the nitrous engine,

exhaust temperature goes up for several reasons. The first is that the power

output has gone up considerably. More power usually produces more waste heat.

Second, the need to keep maximum cylinder pressures within reason has dictated

that the biggest part of the fire happens closer to the exhaust valve opening

time. There just isnít enough piston travel to extract all the energy out of

the charge before the exhaust valve opens. Now, we could and sometimes do, open

the exhaust valve later so more combustion pressure energy can be used to turn

the crank. The trade off is negative torque on the exhaust stroke. If we still

have significant cylinder pressure in the cylinder as the piston moves from BDC

to TDC on the exhaust stroke, your net Hp falls drastically. A real problem at

higher RPM.

You can improve maximum power stroke efficiency and minimize exhaust pumping

losses by running the engine at lower RPM and/or improving the exhaust valve

size, lift and port design. A big nitrous engine likes everything about the

exhaust to be big. If it flows good enough the cylinder will blow down by bottom

dead center, even at high RPM with relatively mild exhaust valve timing. There

are many variables in the design and development of an all out nitrous engine. A

mistake will cause the melt down of any brand of piston. The high strength of

the KB piston will withstand detonation and severe abuse. Unfortunately, all

pistons will melt and when cylinder pressure limits are exceeded, run away

detonation can occur. The excess detonation heat makes the plugs, valves and

piston so hot the ignition system alone can not be used to shut the engine down.

Continued operation worsens the situation to the point of a total melt down.

Designing a maximum performance nitrous engine is more of an exercise in heat

management than it is in engine building.

A lack of a sufficient fuel supply is probably the most common killer of the

nitrous engine. If you add a 300 HP kit to your present 300 HP engine, your fuel

requirements roughly double and a shortage doesnít just slow you down, it

melts things. An electric fuel pump and fuel line devoted entirely to the

nitrous equipment is recommended. Some people add a small "race fuel"

tank just for the nitrous. If you are using a diaphragm mechanical pump to

supply fuel to the carburetor, it is worth while to increase the fuel line I.D.

If the carburetor goes lean while the nitrous is on, the pistons can melt even

with a rich nitrous fuel jetting. The large fuel line trick (1/2" dia.)

only makes a major improvement in the operation of diaphragm mechanical fuel

pumps. It is a waste of time on most electric applications. An electric pump

pushing a mechanical pump is not recommended and does not do well at high engine

RPM. A large size line is effective with a mechanical pump, even if you use

smaller fittings at the tank, fuel pump and carburetor. The advantage of the

1/2" large line is not related to the steady state flow rate of the line.

The advantage relates to the acceleration time and displacement of the pulsating

flow common to the mechanical pump.

High compression ratios can be used with nitrous but shifting the maximum

pressure after top dead center becomes more and more difficult. I prefer to use

street compression ratios and then just work with adding more nitrous to get

desired horsepower levels.

We are currently testing some pistons specifically designed for Nitrous use.

Current "off the shelf" pistons have been successfully run with a 500

HP nitrous kit combined with a Dr. Jacob's nitrous control system. Most of our

effort has been to develop new ideas that will push the limit of nitrous

technology. More testing is planned with a piston especially plated to reduce

detonation.

A beginner would do well to build a reliable high performance engine first,

then advance to nitrous, turbo or supercharging. This makes for more fun, more

education with less head ache and money spent. The book titled "Nitrous

Oxide Injection" by David Vizard, published by S-A Design is stocked in any

good speed shop and should be required reading by anyone wanting to run nitrous

successfully.

John Erb

Chief Engineer,

KB Pistons |