144 MHz - GU74b (single tube) 800W PA

Tnx to UT5JCW Serge for GU74b tube as present

Project based on JH2CLV design

http://www5a.biglobe.ne.jp/jh2clv/handmaderadio.htm

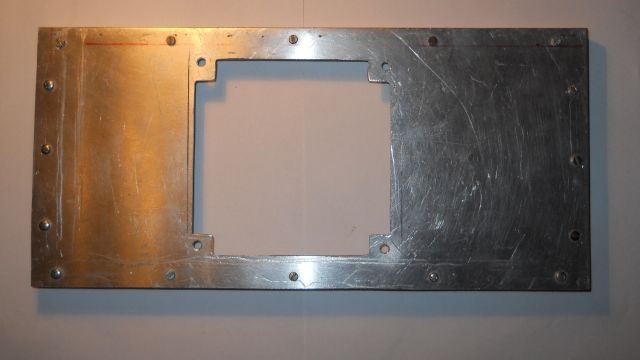

Metal work

Kathode cavity building

Kathode Cavity Progress

L1 details : 60 mm x 3 mm copper 0,25 mm thick

: single turn, 10 mm diameter, on air

Anode Line Progress

Output Circuit

Anode cavity progress

Tube formatting

Trafo (160VA) for : G1, G2, Coaxial Relays (12V, 26V, 48V), Heat and Logical Controller from tetrode board.

Tetrode board controller based on G3SEK design :

GU74b input stage

http://www.ifwtech.co.uk/g3sek/boards/tetrode/tetrode-1.htm

REC-G1-ALC Board G2-CONTROL Board

PA progress

Accessories for tetrode board:

1 Kohm/100W variable resistorsREC-G1-ALC Board ready G2-CONTROL Board ready STP8NK80Z (Q2) - on position

OFF-BOARD COMPONENT CALCULATIONS

1. Rs (SCREEN BLEEDER RESISTOR)

Bleed Current = 10 mA

VG2 = 350 V

Rs = VG2/10 KΩ = 350/10 = 35 KΩ

Rs = 35 KΩ/10W Suggested power = 20W

2. TRIP CURRENT (TO R12)

A = 40 mA

B = 40 x 1,1 = 44 Ma (for each tube)

C = round to next multiple of 10 = 50 mA

Trip Current = 50 mA

3. STANDING CURRENT

Add 20 mA to 50 =70 mA

Standing Current = 70 mA

4. AC VOLTAGE REQUIREMENTS

A = 350 V

B = 350 + 50 = 400 V

C = 70 mA

D = (70 x 0,75) + 350 = 402,50 V

E = round to next multiple of 10 = 410 V

Minimum Unregulated Input Voltages = 410 V

F = 410/1,2 = 341,66 = 342 V

Minimum Transformer Voltage (RMS AC) = 342 V

5. R14 CALCULATION

A = 410 V

B = 350 V

C = 410 – 350 = 60 V

D = 70 mA

E = 60 x 1000/70 = 857,14 Ω

F = 60 x 70/1000 = 4,20 W

R14 = 860 Ω/5 W Suggested 860 Ω/50 W

6. R12 CALCULATION

A = 350 V

B = 70 mA

C = (350 – 80) x 1000/70 + 20 = 3000 Ω = 3 KΩ

E = (70 + 20)² x 2000/1.000.000 = 16,20 W

R12 = 3 KΩ/17 W Suggested 3KΩ/50 W

7. R15

Suggested Value For R15 = 82 Ω / 1W

8. RL - SCREEN CURRENT TRIP

A = 350 V

B = 40 mA

C = 350 x 1000/40 = 8750 Ω = 8,75 KΩ

E = 350 x 40/1000 = 14 W

RL = 8,75 KΩ/ 14 W Suggested 8.75 KΩ/30 W

SUMMARY

Rs = 35 KΩ/10W

R14 = 860 Ω/50 W

R12 = 3 KΩ/50 W

R15 = 82 Ω / 1W

RL = 8,75 KΩ/ 30 W

Trip Current to R12 = 50 mA

Standing Current to R12 = 70 mA

TRANSFORMER FOR G2

Minimum Unregulated Input Voltages = 410 V

Minimum Transformer Voltage (RMS AC) = 342 V

Rs = 33 KΩ /30 W R14 = 860 Ω /50W

R12 = 8,75 KΩ /50W

Rs, R14, R12 in position. All devices in position. Final test can start

project under construction