This description may seem lengthy but the process from printing to a finished board is not more than 15 minutes.

|

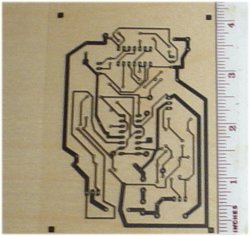

1. I obtained a copy of Eagle PCB, which can be obtained from http://www.cadsoft.de/freeware.htm This is a free version and allows the hobbyist to produce boards up to 100mm x 80mm. This size of board is easy to handle and will enable you to produce designs of a quite complex nature. If the artwork is provided with a design from a magazine or from the Internet you can then begin the process of producing the transparency. Laser printers are now quite cheap and not beyond the hobby equipment. You may have access to one through your local library or school. I use "Paint Shop Pro" available from www.jasc.com to make any changes before printing and to obtain a good black and white transparency of the correct size.

|

2. To transfer the drawing from the Eagle PCB program I have found that the best way is to select a dark blue color for the tracks or bottom in the "display options" and set the Pads and Vias to green. Open Paint Shop Pro and "Paste as new image". It will now print the exact size required.

|

|

3. I have a Lexmark E219 Laser printer capable of 600dpi. The transparency film used can be Kodak Inkjet Transparency film cat. No. 882 0151 or most other inkjet transparencies. Load the film into the printer to print on the SMOOTH side. Set the scale as 1 : 1 and print off the artwork. Do not make a mirror image as this is done automatically during the heat transfer stage. I often print several onto one page and select the best for transferring. |

|

|

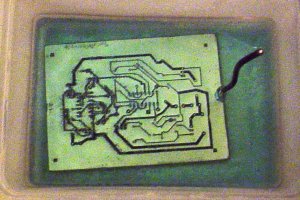

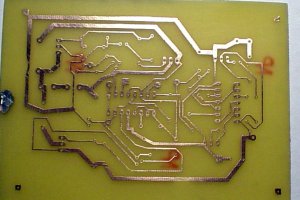

4. If you are not satisfied with the printing and heat transfer of the artwork the markings can be removed from the copper using some lacquer remover obtainable from your local hardware shop and then clean up the copper with steel wool.

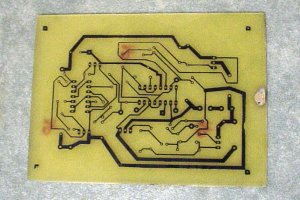

5. To transfer the artwork to the PCB requires a little care. I use an aero modellerís iron with the setting on hot. These irons can be obtained for about $A50. A normal household iron works just as well with a setting around that used for ironing wool. Apply gentle pressure and be careful not to move the transparency. It takes a minute or so for everything to get warm and the laser printing to firmly adhere to the board.

|

|