MAX713 NiMH Battery Charger

I built two versions of this charger, the first for 2, 4 or 6 cells and the second for 1, 2, 3 or 4 cells. The latter was prompted by the need to charge an odd number of cells, seemingly impossible with most inexpensive chargers which need to charge cells in pairs. If I had realized at the beginning that I needed to charge an odd numbers of cells, it could have been done in one charger, with suitable switching.

The chargers use the MAX713 IC which allows you to make a relatively simple and flexible charger. It is possible to charge one to sixteen cells with the correct setup. It helps to read the MAX713 spec sheet; it explains the setting of the PGMx pins, and give you the opportunity to customize the project to your needs.

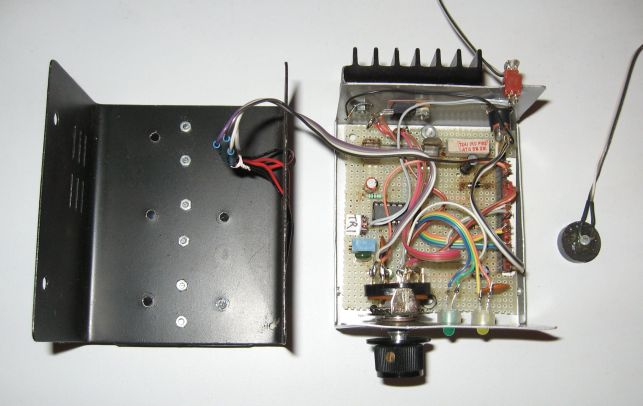

I use the simpler linear mode charge controller. The spec sheet also shows a switching mode controller; this would help to keep the waste heat down. With a linear controller you have to think about how much heat the pass transistor is going to dissipate. A good heat sink is almost certainly necessary.

Previously I used the MAX712 for these chargers. I realized that the MAX713 is more suited to charging NiMH batteries, so I revised the project in Feb. 2013. It's just a matter of removing the MAX712 and inserting a MAX713.

Version 1:

Version 2:

R7 (Rsense) determines the fast charge current. In my case the

value I chose provides around 720 mA, which is a compromise between the

need for speed and the need to take it easy on the lower capacity

cells. With this amount of current I recommend using a 9V supply, to keep the

dissipation in transistor Q1 to a reasonable level when charging one or

two cells. For 6 cells a 12V supply must be used. In any case Q1 needs a good heat sink, and you should make

sure it doesn't get too hot. Its easy to calculate how much heat must

be dissipated by Q1 given the supply voltage, the number of cells being

charged, and the charge current.

In a project like this it is important to minimize the resistance of the circuitry that carries the current to the batteries. In particular look for a good quality switch with low resistance contacts, and good battery holders. I tried 3 different battery holders that all looked the same, but only one had low resistance contacts. Unfortunately the MAX713 is measuring the voltage at pin 2, not at the battery terminal.

The following photos show the version 1 project. The gadget on the right is the thermistor glued to a small magnet.

You must set R5 to trip the charger at some chosen temperature. I use 45 degrees C. Using an accurate thermometer, place the thermistor and the thermometer probe together near a heat source like an incandescent bulb. When the temperature reaches the chosen value, measure the voltage at pin 7 of the MAX712. Then move the voltmeter to pin 5 and set R5 to show the same voltage. (Voltages should be measured against BATT-, not ground.)

Having attempted to build other projects that use thermistors, I know that this is the builder's achilles heel because no one has the right thermistor in their parts box, and obtaining the specified part can be difficult to impossible. The MAX713 spec sheet specifies a 10K ohm (at 25 degrees C) NTC thermistor, and suggests an Alpha Sensors p/n 14A1002 part. This part is not available to hobbyists, forcing a search for a substitute. Beside the "10K @ 25C" specification, the key rating is the "beta", which determines how the resistance changes with temperature. This part has a beta 0/50 of 3889. Using DigiKey's excellent parts search engine yielded a Honeywell bead thermistor p/n 192-103LET-A01, DigiKey p/n 480-3158-ND, which is in stock with a unit price of around C$4.74. The beta is close at 3887 and should work fine. Other close parts are also available if you do your own search. Its not critical, as long as you can achieve the calibration in the previous paragraph. Because of this project I added a thermistor dialog to my HamCalc program.