P.C. BOARD

Etching the board is a process which requires patience. Although the process may take a while to complete, the result of having a professional looking board is well worth the time.ETCHING THE

P.C. BOARD

Safety glasses. It's

a good idea to wear these at all times while working with the etchant.

Gloves. Because

the etchant is a mild acid, it is an excellent practice to wear gloves

at all times when handling the etchant: from pouring the acid into the

etching tray, to working with the board, to cleanup.

Plastic dropcloth.

This protects the working surface from the acid - important since it stains

everything permanently. A plastic trash bag can be used here.

Etching tray.

The etching tray provides a convenient container to process the board.

If you purchased a kit, this is the container for that kit.

Ferric

Chloride. This is the etchant - what actually makes the circuitry.

Ferric Chloride is a mild acid and will permanently stain anything it comes

in contact with (clothing, etc). It will also discolor your skin

and may give you an acid burn. Here's how it works: The acid weakens

the exposed metal (copper) of the p.c. board and literally eats it away.

Registering the board prevents the acid from eating away at the copper,

thus leaving the copper traces ready for you to drill the board and insert

the components. Ferric Chloride works best and fastest when it is

hot - above 100F. See Step 2

if you have a dry powder and need to mix the etchant.

Heat Lamp.

Aids in heating the acid to above 100F.

Scouring Pad.

This comes in handy after you have etched the board.

In addition to those materials

pictured, it is suggested that you have:

Stirring Stick. Stirring

the etchant helps to reduce etching time.

Jar of Water. Helps

to clean the etchant from the board and loosen the tape.

Select a clean, level surface to work. This area must have good ventilation because the heated acid gives off some fumes. If you have purchased the dry powder etchant, follow these directions:

This step requires patience

and good timing in deciding when to remove your board. After you

make your first board, you'll know exactly what "clues" to look for.

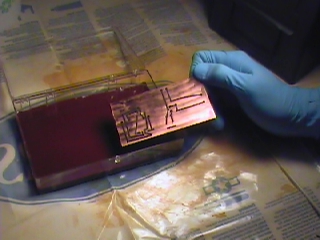

Once the etchant is hot

- and remembering gloves and glasses - place the board into the bath as

shown above. Use the stirring device you selected to stir the acid

frequently (every 30 seconds or so). Stirring drastically reduces

the time it takes to etch the board.

After about 10 minutes,

check the progress of the board. The etching should be noticeable

at this point–especially at the edges of the board. The copper that

is getting etched will turn in color to almost pink. Once the edges

are noticeably etched, check the board more and more frequently.

After about 5-10 minutes longer the board should be nearly complete.

It is important not to go too long because you can actually start etching

the copper out from under the taped traces! Don't worry if the board

is taking 30 minutes or more to completely etch. If your board is

relatively small, try stirring the etchant more frequently.

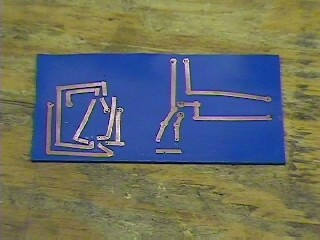

When the etching has been

completed you should not see any exposed copper on the board. Only

the taped traces should remain. If you still see a small amount of

copper on the board, go ahead and etch it off but BE CAREFUL not to etch

too long and undercut the traces. Move on to Step 4 when you are

satisfied with the appearance of your board.

For this step you will

need the scouring pad and the jar of water.

Remove the board from

the acid bath and place it into the jar of water to wash off the ferric

chloride. Once the board has been washed, use a dampened scouring

pad to remove all the traces from the board. The taped tracks can

usually be peeled off or scraped off by hand, but the rub-on dry transfer

patterns are easier to remove with the pad. The scouring pad also

helps to clean the board and the traces after the etching process.

Congratulations!

You have just etched a professional looking p.c. board! Now dry the

board well and let's view the finished board which is now ready for drilling....