Introduction.

When

transmitting or receiving QRSS one of the most important factors to

consider is frequency stability. Even a well designed crystal

oscillator will still exhibit "drift" to some degree. With regular 12

W.P.M. CW or voice S.S.B. a crystal oscillator would be more than

capable of maintaining the required degree of frequency

stability but for QRSS applications it may not be

sufficiently stable.

The single component which

determines the stability of a crystal oscillator more than any other is

the crystal itself. Other components which effect the stability include

any inductors or capacitors used to "trim" the crystals frequency. It

is quite common for the crystal not to oscillate at exactly the desired

frequency with the result that a small trimmer capacitor or some

inductance may be required to bring the frequency to the required

value.

The most common cause of "drift"

in any oscillator is due to the effects of temperature change on the

frequency determining components. In the case of a crystal oscillator

this is the crystal itself and any additional components used for

frequency "trimming". Inductors in particular can be very

sensitive to temperature changes. In order to achieve the highest possible

stability of the oscillator a number of factors should be

observed.

The oscillator should be Solidly Constructed with all the components securely mounted and with short component leads. Secondly, the oscillator should have a Stable Power Supply

and preferably be from a "low noise" source. Some three terminal

Voltage regulators can be very "noisy" which in turn leads to amplitude

and/or phase modulation of the oscillator. Thirdly, the oscillator

should be maintained at a Constant Temperature.

One solution to maintaining both

short and long term frequency stability is to phase lock the crystal

oscillator to a stable

frequency standard, this usually takes the form of a G.P.S. disciplined

crystal oscillator which effectively makes the crystal oscillator as

stable as the atomic clock to which it is referenced. For many this

level of complexity or additional cost may not be acceptable in

which case the next best thing is an oven controlled crystal

oscillator or O.C.X.O. The "oven" maintains the crystal at a

constant temperature and thereby ensures greater frequency stability in

the event of changes in ambient temperature outside of the oscillators

enclosure. After the initial "warm-up" period of the oven both the

temperature and the frequency stability remain much more constant

over time.

M0AYF Crystal Ovens.

Presented here are two crystal oven

designs I have found to be very successful. Both designs have been

built and tested several times to ensure repeatability and reliability.

In both cases the choice of components has been based on currently

available or easy to obtain parts. Most of the parts are not critical

and considerable latitude exists in the components chosen. Both

circuits have advantages and disadvantages but because of the

similarity between the two designs it is possible substitute elements

of one circuit into the other to suit personal requirements and achieve

the required performance.You can build these designs yourself or simply

use them as a guide for your own experiments. Both circuits have been

designed with the

following points in mind.

- Easy to obtain components (from the "junk box")

- Single supply rail (nominal 12 Volt) operation.

- Easy to set-up.

- Stable and reliable operation.

- Reproducible by others.

So here are the designs, the MK-1

is most suited to maintaining the temperature of an entire

oscillator/enclosure. As a consequence of heating the entire enclosure

the design consumes more power than would be required for simply

heating a crystal on its own. However, it offers a very high level of oscillator

stability by virtue of maintaining all the oscillator components at a

constant temperature of around 40 degrees centigrade and maintaining temperature

to better than one degree-C over time. This design is best suited to a QRSS transmitter.

The Mk-2 consumes much less power than the Mk-1 since this design is

intended to heat only the crystal and perhaps one or two additional

components in thermal contact with the crystal. This design regulates

temperature at around 30 degrees centigrade and maintains temperature

to better than one degree-C over time. This design is more suited to

QRSS receivers or to applications in which power consumption is very

important as in portable operation etc.

Important note.

Both of these designs will benefit from good thermal insulation

around the enclosure (Mk-1) or the crystal/trimming components (Mk-2)

by helping to reduce the power consumption. Thermal insulation also

shortens the

"warm-up" time of both ovens and shortens the "cycle time" (time the

oven is ON/OFF) which again reduces power consumption and gives better

temperature regulation.

Choice of oven temperature.

It is a good idea to make the temperature safely above the

ambient temperature to ensure the oven has a good safety margin for

reliable operation. For example, if you happen to live in a very warm

climate in which temperatures often reach 30 degrees-C or greater then

an oven temperature of 45 to 50C may be in order. Here in the UK we

rarely see those kind of temperatures so for the design of the Mk-1 a

temperature of 40C was chosen and for the less power hungry Mk-2 a

temperature of 30C was chosen. The precise temperature is not critical

so for example an oven intended to be stable at 40C which turns out to

be stable at 38C or 43C would be fine so long as that

temperature remains constant after the initial warm-up period. Other

factors which dictate the desired

temperature are power consumption which is generally greater with

higher temperatures and long term reliability of components which is

generally better if the temperature is not excessive. To some extent

the increased power consumption of higher temperatures can be offset by

good thermal insulation of the oscillator enclosure (Mk-1) or the

crystal (Mk-2).

Mk-1 Crystal Oven.

With my first QRSS 30 Mtr TX I

wanted to be as sure as I could be that the stability would be

acceptable both to myself and other QRSS operators so I decided

to oven the entire crystal

oscillator circuit assembly. This was achieved by building the crystal

oscillator as a separate unit housed in a di-cast metal enclosure and

then to stabilize the temperature of the entire enclosure to around 40

degrees centigrade.

This approach turned out to be very successful. With the crystal and

associated oscillator components all maintained at a constant

temperature the long term frequency stability has proved to be excellent. After an

initial warm-up period of about 20 minutes the temperature becomes

stable at around 40 degrees centigrade. The oven then cycles on and off

roughly every thirty or forty seconds and hovers around 40 degrees-C

thereafter to within better than one degree-C.

The schematic for the Mk-1 oven appears bellow, click on the image to see the full sized drawing.

The

choice of op-amp (741) may seem a little "old-hat" in the 21'st century

but this ensures stability. The 741 is a very "tame" device and works

well in this application. To give an indication of the stability of the

circuit using the 741 op-amp I can confirm that in bread board tests I

was able to remove all the power supply decoupling components and the

circuit remained perfectly stable in operation.

Important note.

Although the precise value of Ra, Rb, Rc and Rd are not critical two

points should be observed. The resistors Ra, Rb, Rc and Rd should be

matched for value using a multimeter. This helps when in comes to

setting up the circuit. If the "spread" in the value of resistance of

Ra, Rb, Rc and Rd due to tolerances is to great it can result in the circuit not

"balancing" correctly and in extreme cases the oven never switches on!

The other point worth mentioning is that the values of Rc and Rd should

not be below about 10 K-Ohms, this is because excess current through

the thermistor will cause "self heating" of the thermistor and

a consequent error in temperature regulation. For this reason values

between 10K and 20K are recommended.

The NTC bead thermistor used was an STC type G13CW which I think is now

"extinct" but to give you some idea of its parameters I measured the

resistance

on a sample to be 800 Ohms at 24C and 520 Ohms at 40C This represents a

change in resistance of roughly 17 to 18 Ohms/degree-C Any bead

type NTC thermistor which matches these parameters should be suitable.

If you have difficulty obtaining such a component the "fear not", the

Mk-2 oven below uses a common small signal transistor as the

temperature sensor which could be incorporated into the MK-1 if

required.

Operation.

The resistors Ra, Rb, Rc and Rd form a bridge circuit. The

"balance" point of the bridge has been chosen to be around +5 Volts or

a little higher. The balance Voltage is not critical but because of

limitations of the 741 operating on a single supply rail the 5/6 Volt

level was chosen to give reliable operation with plenty of "head room"

to spare. Resistors Ra, Rb and the S.O.T. (Select On Test) component provide a Voltage to

the inverting input of the op-amp which is about half the supply Voltage or +5 Volts with the 10 Volt zenor diode fitted

as shown in the schematic above. The non inverting input of the op-amp also receives around

half the supply Voltage from resistors Rc, Rd and the NTC thermistor.

At the instant of switch-on the oven temperature will be lower than the

desired value so the NTC thermistor resistance will be at a value

greater than it would be at the ovens operational temperature. This

means the Voltage on the non inverting input of the op-amp will be

slightly greater than the Voltage on the inverting input. This results

in the op-amp output going "high" to very nearly the supply Voltage.

This in turn forward biases the BD681 Darlington which passes current

through the 33 Ohm resistor (the heating element) in its emitter. As

the heating element temperature rises so to does the oscillator

enclosure to which it is attached. As the enclosure temperature rises

this in turn warms the NTC thermistor (also in thermal contact with the

enclosure) the resistance of which falls. The fall in resistance

of the thermistor also causes the Voltage on the non inverting input of

the op-amp to fall, as the Voltage approaches the Voltage present on

the inverting input the output from the op-amp begins to fall. This

falling output reduces the forward bias to the BD681 and results in

lower current through the heating element.

Falling current through the heating element results in less heat

dissipation and a corresponding reduction in the temperature of

the enclosure. Now, with the enclosure temperature falling the NTC

thermistor resistance begins to increase again. This increase in the

thermistors resistance results in the Voltage to the non inverting

input of the op-amp to rise again, as the difference between the

Voltages on the inverting and non inverting inputs increases the output

Voltage from the op-amp also increases and the cycle begins all over

again. After a short time (about 40 minutes with my oscillator

enclosure) the oven becomes stable at the desired temperature which is

set by adjustment of the S.O.T. (Select On Test) resistor value. After

the oven reaches

the stable operating temperature it will "cycle" on and off continually

to maintain the desired temperature. Note that the operation of this

oven is "cyclic" with a very definite "ON" and "OFF" state, this is due

to the lack of a negative feedback resistor from the output of the

op-amp back

to the inverting input of the op-amp. This does not cause a

problem

because of the thermal inertia of the enclosure, that is to say that

even though the heating element may switch off fairly quickly the

enclosure cannot change its temperature as quickly and so the

thermistor still "sees" a gradual change of temperature with the result

that the system is stable. In my own tests the temperature remained

stable to within better than one degree-C of the desired (40C)

temperature. The on-off operation also gives rise to a definite on-off

action to the L.E.D. connected to the heating element and so gives a

"reassuring" indication of correct oven operation. If any problems are

experienced with instability then a 1 Mega Ohm resistor can be fitted

between the op-amp output pin and the inverting input. Experiment with

values between 1 and 5 Mega Ohms.

Below are a few images of the Mk-1 oven showing the mounting of the

heating element (33 Ohm 50 Watt resistor) and the thermal insulation used to

retain the heat.

Click on the thumbnail images to see the full sized pictures.

Constructional notes.

Hopefully

the three images and text above give enough detail to enable others to

implement a similar oven design. Here are a few extra notes to help. My

advice to anyone not familiar with this type of circuit would be to

build the control circuit on a bread-board or a scrap of copper clad

board in order to get a "feel" for the operation of the circuit before

building the final version. I found this was very helpful when I built

my first version of the oven and the experience gained made setting up

of the "neat" version much more straight forward.

The first image above shows how the heating element (50 Watt resistor)

is mounted. The resistor is bolted to the metal oscillator enclosure

with a small amount of heat sink compound between the resistor and

enclosure surfaces to improve thermal contact.

The second and third images above show one possible method of

providing suitable heat insulation to the oscillator enclosure. The

heat insulation I used was the foam padding previously used to package a

computer hard disk drive, this was simply "recycled" into its new role

as thermal insulation. The whole assembly was then placed in a "bubble

wrap" polythene bag to give a second layer of insulation.

One factor I found to be very important was the positioning of the

thermistor. In testing it was found that the oven performed at its best

when the thermistor was in contact with the enclosure and located as

close as possible to the heating element. I found the best way to

achieve this was to mount the heating element on the outside of the

enclosure and the thermistor on the inside of the enclosure directly

underneath the location of the resistor. The diagram below should make

this clear.

The

thermistor is held firmly in position by epoxy resin glue (Araldite),

also mounted close to the thermistor is a 10uF tantalum capacitor which

is used to decouple the thermistor and prevent any possible "pick-up"

by the thermistor connecting leads. The inclusion of this capacitor

means that the thermistor has to be connected to the rest of the

circuit taking care to observe the correct polarity for the capacitor.

For this reason I would suggest marking the wires or using colour coded

wires. e.g. Red for the positive terminal and black for the negative

terminal.

Tip.

The negative connection to the thermistor should not be connected to

the metal box or the oscillator circuit board to provide an earth return since this can lead to "earth loop"

problems and instability. Its better to bring the wires back to the temperature control board and connect them there.

Below is an image showing the oven control board which was assembled

on a piece of strip board. Since the circuit is very stable

the layout is not too critical and the image is shown simply as a

guide. Note the small heat sink fitted to the BD681 Darlington.

Click on the thumbnail to see the full sized image.

Setting-up of the Mk-1.

The following set-up procedure assumes you have read the Important Note above.

Note, what follows is not the only possible method of setting up the

oven circuit but I have found it to be pretty reliable and

repeatable. You will need some form of temperature measuring device in

thermal contact with the oscillator enclosure in order to monitor the

temperature.

Temporarily replace the "S.O.T." (Select On Test) resistor (refer to Mk-1 schematic above)

with a 1 K-Ohm variable resistor, set this variable resistor to the

middle of its range. With the oven enclosure temperature at around 18

to 21 degrees centigrade (not critical) perform the following

procedure. Using a multimeter connect one probe to the junction of Ra

and Rb, (refer to Mk-1 schematic above) , now connect the other probe

of the multimeter to the junction of Rc and Rd. The reading should be

as close to zero Volts as possible. The polarity of the meter does not matter for this test as we only want to check for a zero Voltage condition.

If the reading is not at zero Volts then adjust the 1 K-Ohm

variable resistor until a zero Voltage reading is obtained. Now

observe the "oven-on" L.E.D. which may or may not be lit at this time.

If the L.E.D. is not lit then read on from the "If the L.E.D. is not lit" paragraph below. If the L.E.D. is lit then read on from the "If the L.E.D. is lit" paragraph below.

If the L.E.D. is not lit....

If the L.E.D. is not lit then adjust

the 1 K-Ohm variable resistor very carefully so as to reduce its value

and observe the L.E.D. As the value of the 1 K-Ohm resistor is reduced

(carefully) a point should be reached at which the L.E.D. lights up.

When this happens stop adjustment of the 1 K-Ohm variable resistor and

check the oscillator enclosure is warming up, this may take a few

minutes.

If the L.E.D. is lit....

If the "oven on" L.E.D. is lit up then carefully adjust the 1

K-Ohm variable resistor so its resistance is increased and observe the

"oven on" L.E.D. Continue to adjust the variable resistor until

the L.E.D. goes out then carefully adjust the variable resistor in the

opposite direction until the L.E.D. just lights up again and then stop

the adjustment.

Wait for a few minutes and check if the oscillator enclosure is warming

up, you should find that after a few minutes the L.E.D. goes out.

Now carefully adjust the 1 K-Ohm variable resistor to a slightly lower

value and the L.E.D. should light up again.

Keep observing the L.E.D. and if at any time the L.E.D. suddenly goes

out and the oven has not reached the desired temperature then re-adjust

the 1 K-Ohm variable resistor to a slightly lower resistance until the

L.E.D. again lights and then wait for the oven the warm up to the

higher temperature. Repeat this process until the oven reaches the

desired temperature. Then leave the oven on for a while without

altering the setting of the 1 K-Ohm variable resistor. Depending on how

well you have thermally insulated the oven you should now find the

L.E.D. goes on and off at regular intervals of around 30 seconds to 1

minute. These figures are only a guide and depend on the size of

enclosure, quality of thermal insulation and other factors.

The

adjustment of the 1 K-Ohm variable resistor must be done carefully

since the working threshold of the circuit is fairly narrow so slight

changes in resistance will make larger changes in the operating point

of the oven circuit. Remember, this is a bridge circuit and as such it

is quite sensitive to small changes.

When you are happy that the oven is operating correctly and at the

required temperature then switch off and carefully remove the variable

resistor taking care not to alter its setting. Now measure the value of

the variable resistor and fit a resistor or combination of

resistors which correspond to the same value as the variable resistor

setting and place them in the position of the S.O.T. component. Switch

on again and re-check the operation and working temperature of the

oven. If you have measured the variable resistor value carefully and

replaced it with a closely matched fixed resistor then the

temperature/operation should be correct. Don t worry to much if the

exact temperature is a degree or two away from the target value, what

is important is that the final value of temperature remains constant.

So 38C is close enough to the 40C target so long as it stays at 38C

over time. I would not recommend leaving a

variable resistor in the circuit as a permanent fixture, in my

experience they are often prone to "drift" or failure.

Mk-2 Crystal Oven.

The Mk-2 oven is very similar in

design to the Mk-1 except for two important differences. Firstly, the

MK-2 was intended to be used in a small direct conversion receiver to

ensure stability of the crystal oscillator. Because of the small

physical size of the receiver and the desire to consume less energy it

was decided that only the crystal and its "trimming" inductor would

be temperature stabilized. Also the temperature of the Mk-2 has been

set to 30C which is around 10 degrees lower than the Mk-1. Since my

shack has never reached anywhere near 30C I felt this was justified and

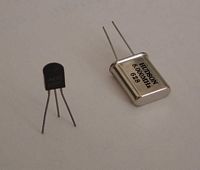

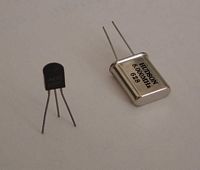

also saves energy.

Secondly I wanted to find an alternative to the NTC thermistor used in

the Mk-1 since this could be the one component which may prove

difficult to obtain in the future. Therefore the thermistor has been replaced by a

small signal transistor which acts as the temperature sensor in the

Mk-2.

How and why the transistor heat sensor works.

In any transistor the forward biased base/emitter junction current will

increase with temperature. This increase of current with temperature in

the base/emitter junction also causes a corresponding and amplified

increase in emitter/collector current through the device. With an NPN

transistor this change of current with increasing temperature results

in a fall in collector Voltage. Conversely, when the device temperature

falls the collector Voltage will rise. This change of Voltage can be

used as an indication of the junction temperature of the transistor and

of the temperature of anything it happens to be in thermal contact

with.

The schematic for the MK-2 appears below, click on the image to see the full sized drawing.

The

operation of the Mk-2 is essentially the same as the Mk-1 except that

the thermistor has now been replaced with an easily obtained NPN small

signal transistor. The operation of the circuit remains the same and

the explanation for the operation of the Mk-1 equally well explains the

operation of the Mk-2 with one exception. In the Mk-1 the oven

operation behaves more like a switch with a definite on-off operation.

Because of the thermal inertia of the enclosure this is acceptable. In

the Mk-2 however it was felt that the much lower thermal inertia

of the crystal encapsulation might lead to small changes in frequency

each time the oven switched on and off. To ensure this does not happen

a 2M2 (two-point-two Mega Ohm) resistor was fitted between the output

of the op-amp and the inverting input. This negative feedback has the

effect of

changing the operation of the oven such that after the initial

warm-up period the oven does not switch off but simply reduces the

supply of current to the heating elements/resistors. As the temperature

falls the current to the heating elements/resistors is increased again

but the whole process is more gradual and results in a "mean"

current being established in the heating elements/resistors such

that just enough energy is dissipated so as to maintain the desired

temperature. This action can be seen by observing the indicator L.E.D.

connected in parallel with the heating elements/resistors. When first

switched on the L.E.D. will be at full brilliance but after a few

minutes the oven reaches its operating temperature and the L.E.D.

"dims" slightly indicating the current through the heating

elements/resistors has also reduced. Thereafter the L.E.D. will remain

on with only slight alteration in brightness as the circuit performs

its function. In tests the value of the feedback resistor

proved to be non-critical and values from 1 Mega Ohm to 5 Mega

Ohms all worked. 2.2 Mega Ohms just happened to be convenient and gave good results.

Construction.

Compared with the Mk-1 some

minor differences exist

in the construction of the Mk-2 circuit. These minor differences

include

the heating element for the crystal which now comprises of just two 100

Ohm resistors in series mounted on the crystal body with epoxy resin

glue. The temperature sensor transistor is also mounted on the crystal

body on the same side as the heating elements/resistors. Finally, any

inductors that may be required to "trim" the crystal frequency can

also be secured to the crystal body on the opposite side to the heating

element/resistors. This is shown in stages in the images below. Also

shown in the images below is the Mk-2 control board which is built

on a small piece of strip board. Note that because of the reduced power

dissipation and lower currents involved with the heating

elements/resistors the BD681 Darlington no longer requires a heat sink

to be fitted.

Click on the thumbnails to see the full sized images.

The fourth image above shows the

crystal mounted in my 30 Mtr DC-RX with some yellow thermal insulation

wrapped around it and the final image shows the Mk-2 oven

control board which is built on a small piece of strip board.

Setting-up.

The

first thing to do is select a suitable device for Q1 (see schematic

above) which can be almost any NPN small signal transistor. I used a

BC238B plastic packaged device because it had one flat face ideally

suited for attachment to the crystal body (see photographs above)

and I already had several of these in my junk-box. With a 10 K-Ohm resistor in

the collector and a 2M2 (two-point-two Mega Ohm) resistor

from the collector to the base (as shown in the schematic above)

connect your supply between the free end of the 10 K-Ohm resistor

(Positive connection) and the emitter (Negative connection) of Q1. The

supply should be set to12 Volts or whatever Voltage you intend to

operate your oven circuit from. If you do not intend using a stabilized

supply and plan to fit the 10 Volt zenor (shown in the schematic

above) then for this test set your supply to 10 Volts. Now measure the

Voltage on the collector of Q1 with respect to the negative supply

rail. The Voltage on the collector should be very nearly half the

supply Voltage (5 Volts in the schematic above) at 21 degrees-C but

don't worry if its not. Simply replace the 2M2 (two-point-two Mega Ohm) resistor

for another one until you get the required half supply Voltage at

around 21 degrees-C. Increasing the value of this resistor will reduce

the forward bias on Q1 and cause the collector Voltage to rise,

reducing the resistor value will increase the forward bias on Q1 and

cause the collector Voltage to fall. If selection of a suitable value

of resistance proves difficult then try a different transistor for Q1

and repeat the operation.

When you are happy that you have

selected a suitable device for Q1 and found a suitable biasing resistor

you can then attach the transistor to the crystal body (see images

above as a guide) along with the two series connected 100 Ohm heating

elements/resistors. When the glue has set solder the 10 K-Ohm collector

resistor, the base biasing resistor and the 100 nF capacitor to Q1

"ugly style" but as neatly as possible and use more glue if required to

secure the components. Finally, bring three identifiable wires out from

the Q1 circuit which will connect to the oven control board. The three

wires are connected to Q1's emitter, Q1's collector and the free end of

the

10 K-Ohm collector resistor.

Tip.

The negative connection to the transistor emitter should not be connected to

the metal box or oscillator circuit board to provide an earth return since this can lead to "earth loop"

problems and instability. Its better to bring the wires back to the temperature control board and connect them there.

The

final stage of setting-up is to select a suitable resistor for the

S.O.T. (Select On Test) resistor (see schematic for Mk-2 oven above)

which should be about 9K1 as a starting point. Using some sort of

temperature measuring device check the temperature of the crystal body

and switch on the oven circuit, the "power-on" and "oven-on" L.E.D.'s

should light up. After a short time the crystals temperature should start to

rise.

At around 30 degrees-C the temperature should stabilize, if the

oven does not reach 30C then reduce the value of "S.O.T" by about 50

to Ohms and re-check the stabilized temperature. If the

temperature is

now to high then increase the value of "S.O.T." slightly. Continue

adjusting the value of "S.O.T." until the desired temperature is

achieved. Selection of S.O.T. can be done more quickly by using one fixed

and one variable

resistor in place of the S.O.T. component. A fixed resistor of

around 8 K-Ohms with a 2 K-Ohm variable resistor in series should prove

satisfactory. When the correct setting has been found these components

can then be

carefully removed, the total resistance of the two series

components measured and then replaced by a fixed

resistor or resistors of the correct value. I would not recommend

leaving a variable resistor in the circuit as a permanent fixture, in

my experience they are often prone to "drift" or failure.

The Mk-3 Crystal Oven.

O.K.... So there is no Mk-3 oven...

yet! But if/when it arrives (still at the "back of my mind stage") it

will most likely retain many of the "tried and tested" features of the

Mk-1 and Mk-2. The junk box signal transistor temperature sensor and

the "tame" 741 op-amp will be retained. To reduce power consumption and

improve efficiency the BD681 could be used as the crystal heating

element by attaching it to the crystal and using the power dissipation

in the device to heat the crystal. This would improve efficiency

because it would be the only component dissipating any significant

energy. The Mk-2 is pretty good but wastes some energy as heat in the

BD681 which is simply lost. By dispensing with the heater

element/resistors and using the BD681 itself to heat the crystal the

efficiency should be slightly higher.

If this sounds like such a good idea you simply can't wait for the Mk-3

then have a look at the QRSS page of G4OEP (just over half way down) in

which he has presented a design which operates in a manner very

similar to the description above. The only significant difference is

that the design uses a thermistor as opposed to the junk box transistor

used in the Mk-2 oven above. With a little ingenuity the features of

both circuits could be combined.

The QRSS page of G4OEP

I hope this has proved interesting and useful.