HOW TO UNSOLDER AND RECOVER OLD ELECTRONIC COMPONENTS

I don't

know if what I'm going to explain is a "well-known" thing, but sure it

has been useful to me;

I mean the easy and quick way I use to recycle thousand of old electronic components coming

from old

electronic boards (SMD and not);

INTRODUCTION

Years

ago I started with a simple solderer and the electronic board fixed in a vice:

this system works, but it's slow and uncomfortable, it's not possible unsolder

SMD device or simple IC (or, better, it's very hard);

so I unsoldered only something interesting;

Then I've tried with a gas-torch: but after few minutes the board burned and it was not possible go on: No good system.

With a lot of double-face board in my cellar (impossible to unsolder with a simple solderer) I've tried cutting the board all around the IC; when needed, I unsoldered the IC from the small board remained, but sometimes the IC's pin broke: No good system.

FINALLY

Nicola (IK7IMK) suggested me a new system;

I was sure that the key of success was hot-air, but I didn't suppose it was so

easy, cheap and fast....

All you need is a "hot-air gun"; I've purchased one in a local

supermarket for less than 15 euro;

It should be 1500-2000W and have double speed/temperature (300 and 600 C);

The low temperature position is to be preferred, but sometime also the high one

is useful.

I made

the first test with the gun in the vice and up the board with components;

when tin fuses, I overturn the board on the table and all components (unsoldered)

remain on the table;

this system works but have same problems: when you overturn the board on the

table, tin goes on the components so sometime you need to clear it;

moreover sometime SMD device can go into the gun blocking the small driving;

So I've inverted the situation (the board on the table, the gun in my hand ): it works better but is not as comfortable as I want.

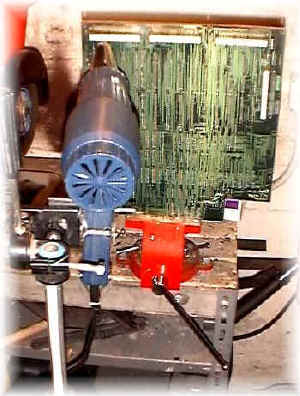

So I've tested the last and best system:

the

electronic board is in the vice (vertically);

the hot-air gun is mounted on a tripod; starting from the botton-right side I

unsolder components moving the gun up (the tripod have a built-in

mechanism);

with a flat-nose pliers I quickly remove components from the opposite side of

the board;

when the gun is in the upper side, I move the board a little bit left (or right)

in the vice moving the gun up to down and so on until all components in the

board are unsoldered ;

With this system the work is very easy, quick and "pleasant";.

Moreover I have the hands free to make other job during the while.

Just 2

words about how I "work";

The first thing is take to pieces mechanically until you have the only

electronic board; then proceed with the hot-air gun.

After unsoldered, order components for family:

Fixed

resistor

Trimmer

Variable resistor

Electrolityc Capacitor

Ceramic capacitor

IC

diode

transistor

other mechanics

ecc. ecc.

Then I order single family for value: 1-10-100-1K 1k2 ecc.;

About diode, transistor and IC I download datasheet from internet (you'll

find all you need on http://www.freetradezone.com)

(you need to login before)

Please

make all the work outside, in open place: new electronic board are very hard to

burn but old one burn very soon and that smoke is not very good for your health.

Do not exceed with temperature because it's the first cause of damage for electronic device.

From the day I've started using this system, I have a lot of electronics components (sometime I have to throw away some components to have free place for the new HI!) and , of course , I don't have to go to the local shop anymore.

73 de iz7ath, Talino Tribuzio