Kenpro KR-600RC rotator information

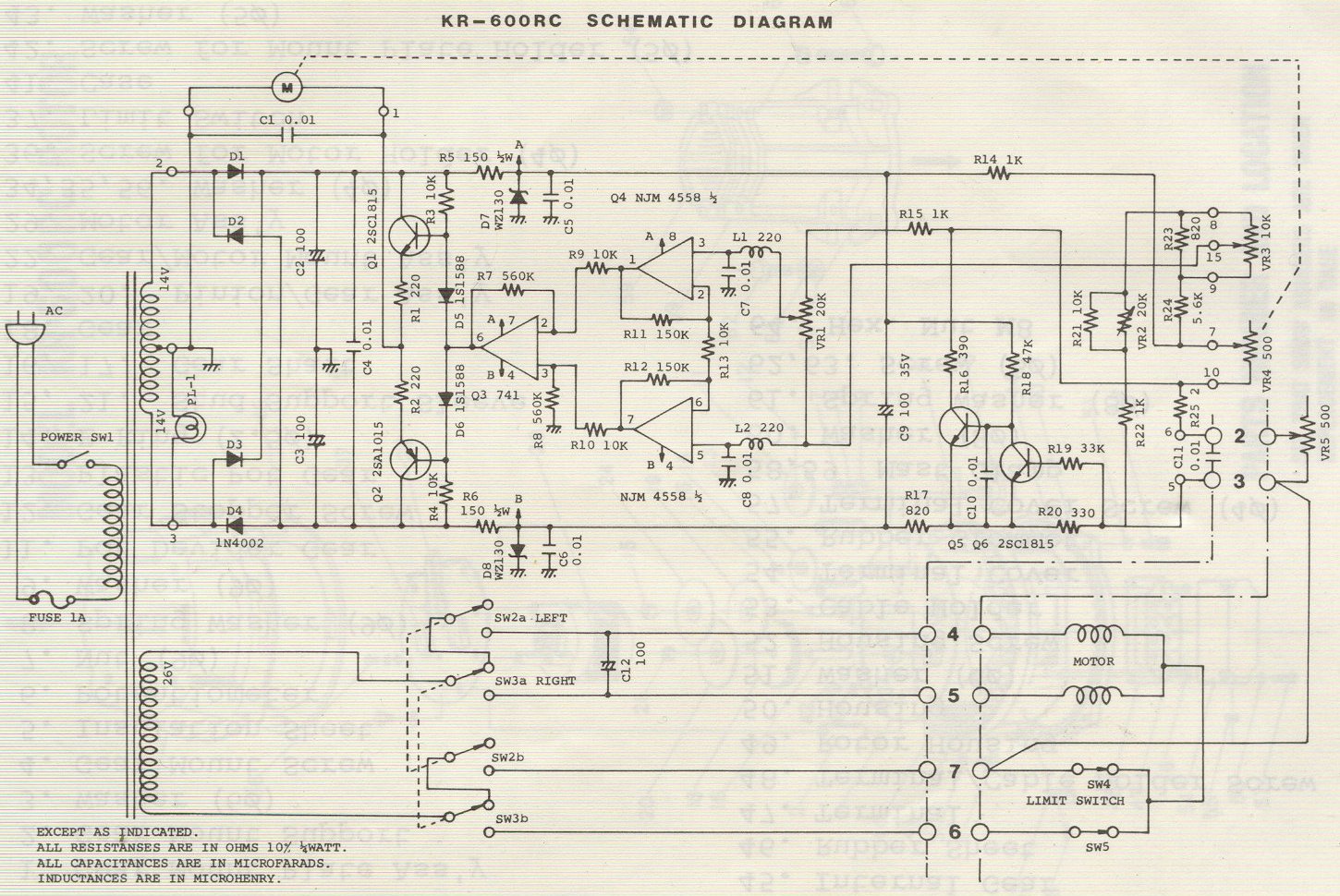

Controller - schematic

KR-600RC notes : VR5 is a gear-driven pot inside the rotator head-unit/bell housing. When reassembling, make sure VR5 is positioned to cover the correct part of its track i.e. avoiding the 'dead zone' where the connections inside VR5 are - in my rotator this gives a range from approx. 41ohms fully CCW to approx. 650ohms fully CW (i.e. more than the 500ohms max value shown on the schematic) VR4 is a gear-driven pot inside the controller, driven by the indicator motor. VR1 is a preset pot on the PCB, the right-hand one (as seen from the side of the controller) and VR2 is also a preset pot, the left-hand one on the PCB. VR3 is the 'set full-scale travel' pot mounted on the rear panel of the controller.

Fault symptoms - my KR-600RC had a fault - the indicator did not read properly and the pointer was 'hunting' - whirring and moving back and forward over a very limited range.

Fault finding - after testing the potentiometer in the rotator unit (VR5) and the continuity of the multicore cable, I took several hours to find that pot VR4 in the controller unit was faulty. VR4 is a 0-500ohm pot which is driven by the indicator motor - its position should mirror the position of VR5 in the rotator unit. Inside VR4 the wiper is held in place and tensioned by a tiny (0.8mm approx) brass rivet - this rivet had broken allowing the wiper of VR4 to move freely and only touch its track intermittently. Replacement is difficult unless you can source a replacement pot - you actually need a pot which can turn 360o or more without damaging itself internally, and you need a pot which has roughly the same maximum resistance as your VR5 in the rotator - in my case this is 650ohms. I've had to use an unsuitable potentiometer until I can find a suitable one, but the fault is fixed. Setting the 5 potentiometers used so that they work together is quite difficult - I recommend taking the back cover off VR4 so that you can watch the position of the wiper to ensure that it does not get damaged by travelling over any end-stops. VR1 is like a 'sensitivity' control for the feedback loop, while VR2 and VR3 work together to set the 360o rotation range of the indicator pointer.

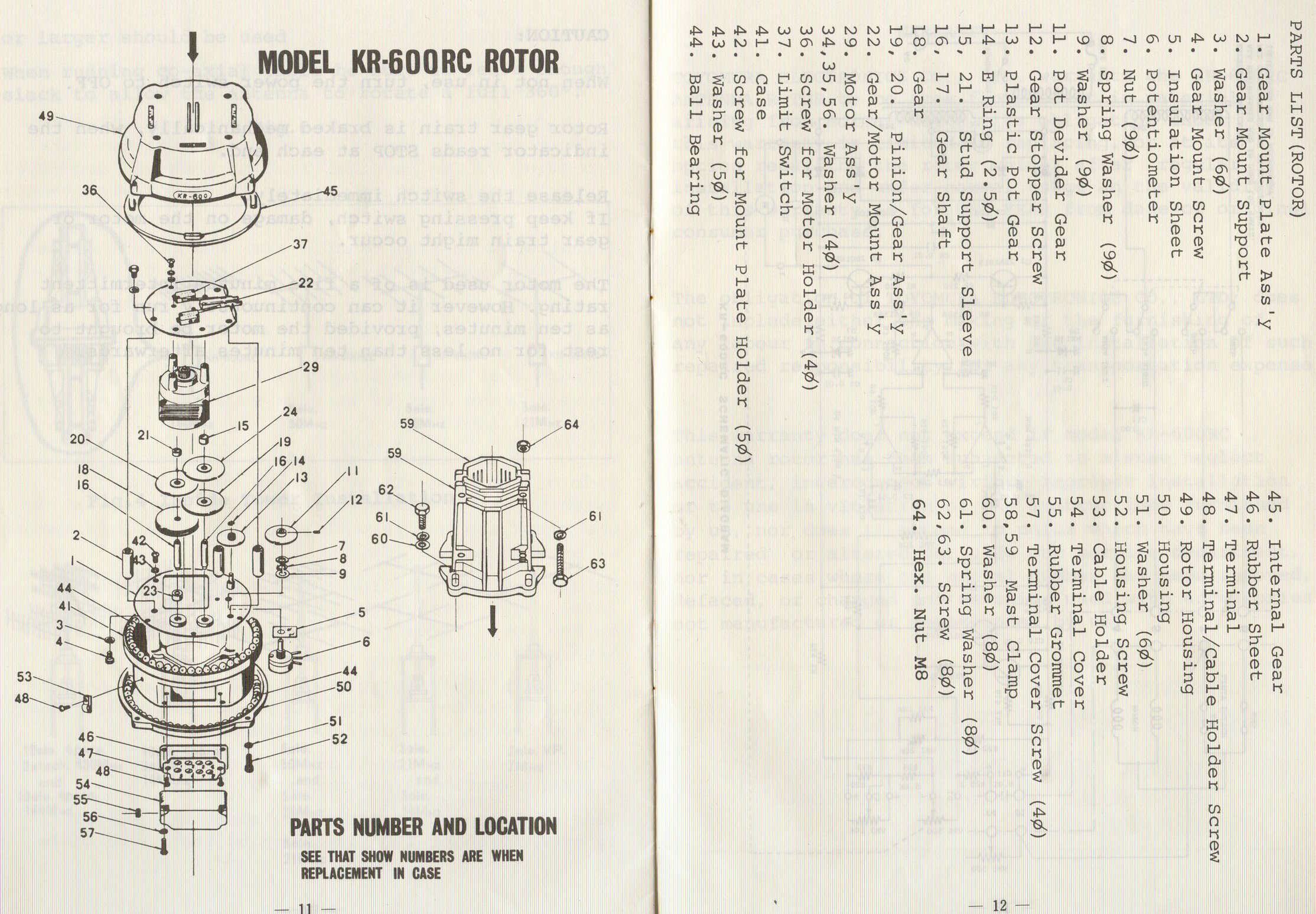

Rotator - parts