Control System for Multiband Microwave Station

Introduction

Over the

past few years I have been using PIC microcontrollers in a number of projects.

This started with a 2m transverter and control unit

which drives transverters for 13, 6 and 3cm, and continued

with my 23cm SSPA. This latest project extends that a bit further, using a more

modern PIC device.

The new

control box is intended to allow both of my HF prime mover rigs to be used with

a range of transverters. My Elecraft

K3 has been dedicated to 1.3GHz operation up to now, but it has many advantages

over the Elecraft K2 used for the high band transverters, so it makes sense to link it to a wider range

of kit. Retaining the K2 allows a degree of SO2R (Single Op 2 Radio) operation

in major contests, but it does mean that the control box has to resolve

conflicts between the

At the same

time I have taken the opportunity to support some future changes to the

station. I plan to replace my aging FT736R (used on 432MHz and transverting from there to 3400MHz) and existing 250W valve

PA with a new transverter from 28MHz and a new SSPA,

so the control box is designed to support this arrangement. I also plan to

change the dish feeds for 2.3 and 3.4GHz to concentric loop feeds, but this

means that isolation between the feeds will be quite low so an interlock is

needed to stop transmit power getting into the receiver front end for the other

band.

I have also

added a “transverter enable” feature which allows

unused transverters to be powered down, or the LO

injection disabled. This will reduce some IF breakthrough problems from the

local GB3MH* beacons, and make it easier to listen for weak beacons.

A couple of

future additions are catered for, one is a socket for a second K3 if I should

ever get round to replacing the

Design

Control Inputs

All of the

switchbox operation is controlled by the

The control

inputs are taken from parallel interfaces on the

RF Switching

The switch

box is based on two switching matrices, one for receive and one for transmit.

Each can connect either of two inputs to four outputs. These matrices are used

to switch the low level 28MHz IF signals to and from the K2 and K3 to transverters for 70MHz, 144MHz (and 2.3, 5.7,10GHz), 432MHz

(and 3.4GHz) and 1.3GHz. The relays used (NAIS TQ2 range) are relatively cheap

but have reasonable RF performance at 28MHz, and are configured to maximise

isolation in the off state. Measurements made indicate that the minimum

isolation is 65dB, and through loss is negligible (<0.1 dB). Each switch

matrix board is controlled by a serial interface driver chip,

the two boards are cascaded and driven by three lines from the main control

processor (clock, data, and latch signals). The switch arrangement does allow

both receivers to be connected to one transverter if

required.

Control Lines

To provide

the transverter enable function I have used stereo

3.5mm jacks for most of the interfaces, with conventional “ground to transmit”

on the tip of the jack, and “ground to enable” on the ring contact. This means

that mono 3.5mm jacks can be used to operate transverters

with no enable features, but there is an easy upgrade path as I add this

capability to each band. The software support for transverter

enable is included in the initial build.

One exception

to the rule is 144MHz where the transverter control

also carries band select outputs to select higher band transverters

– this allows the existing transverter and switch box

to be used without modification. The other is the control connector for the

future 432MHz transverter which will also support the

3.4GHz transverter, so again a band select line is

also required.

All of the

control lines are driven by darlington

relay driver interface chips which provide a robust interface to the outside

world, they can sink currents of up to 500mA and withstand voltages to 50V. The

only downside is that the on state voltage drop is fairly high (about 1.2V)

which needs to be borne in mind with some interfaces.

LED indicators

LEDs are

used to indicate what band is in use for each rig, and whether on transmit of

receive. An LCD digital display might be simpler, but the LED status display is

easy to take in at a glance. The LED for a selected band will be Green on

receive and Red on transmit, all other LEDs for that

prime mover will be off. Any clash for resources will result in one rig

“winning” (generally the K3) and the LED for the other rig will display Amber

(by rapidly switching between Green and Red). The only exception to the K3

winning any contention is the interlock when the

Processor

The heart

of the control box is a PIC16F884 midrange PIC microcontroller. Even though

this has 36 I/O pins this is not sufficient for this application, so the

outputs are expanded in various ways, the serial interface to the switch matrix

relay driver being one example. For the control interface outputs two octal

latches expand Port C to give 16 lines. The LEDs are

driven from BCD decoders on two further latches on Port C. The BCD decoders

allow the bidirectional dual LEDs to display either Red, Green or nil by switching on the appropriate BCD

output.

Firmware

The

firmware was written in assembler and then built and tested using MPLAB-IDE

tools. The firmware structure is as follows:

Initialisation

The PIC

runs through a sequence of steps to initialise the registers as required and

select the required options. It then outputs a sequence of 16 zeros on the

relay control line and latches this to clear all the relays (note that the

relays can all be in the on state initially, which considerably increases

current draw, hence the need for a 7805 regulator rather than a 78L05). Next it

runs through a routine that flashes all the LEDs in

sequence, first Green then Red.

Input Routine

The code

then jumps to the main loop where the PIC waits for changes on the input lines

from the K3 and

Output Routine

The output

routine executes a sequence of reads of look up tables for the required logic.

There are two look up tables in program memory, the first for the K3 has 32

entries per section and is accessed based on the Band0 – Band3 signals and the

T/R state on the KeyLP line. The first two sections

set the required relays in the switch matrixes for transmit and receive, the

next section sets the LED states, the next two sections set up the relay

control outputs, and the final section drives the 144MHz transverter

parallel interface. The

Having

filled registers in the PIC with the required conditions from both tables, the

next section performs a logical OR function to create

the final values to be output. The final stage is a check on collisions for

resources, this looks for situations where both rigs are on the same band, or

where the 144MHz transverter is being requested by

both rigs (eg one on 2.3GHz and the other on 10GHz).

This code section also provides the interlock between 2.3GHz and 3.4GHz so that

the transverter enable signal is removed when the

other one transmits. If all these conditions are satisfied then the port

registers are updated to drive the external outputs as required. If a collision

is detected the LED of the rig inhibited is flashed rapidly red/green (at about

100Hz) so that it appears Amber. This is done by changing the LED state every

256th time round the main input loop.

I’m happy

to provide more details of the hardware (schematics/board layouts) – please email

me if you are interested. The firmware is going to be bespoke for every station

so I won’t be releasing code but some key design features are included above.

Figure 1 Overall Switching Configuration

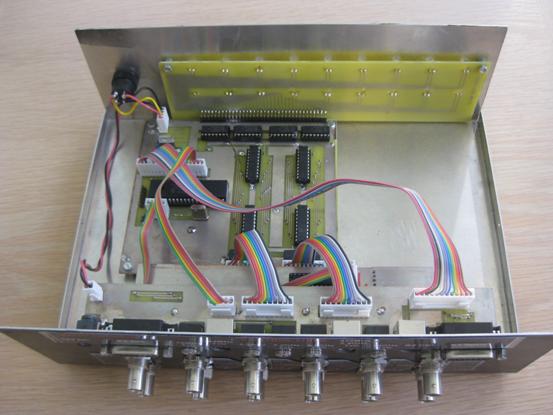

Figure 2 Overall Switch Box

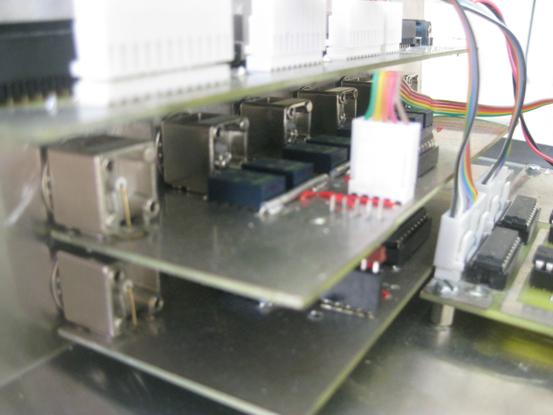

Figure 3 Switch Matrix Board

Figure 4 Rear Panel View