In the fall of 2017 I had come into contact with Peter, OZ8CTH. He complained that the PTO inside his KWM-2 had become quite unstable, showing a large drift at warm-up and occasionally some jumps in frequency.

After some discussion we decided to remove the PTO from the KWM-2, open it, check all elements and definitely replace all the capacitors and diode CR301. So the 70K-2 PTO #14289 made its way to Hannover, together with a small bag full of new parts (see below for details).

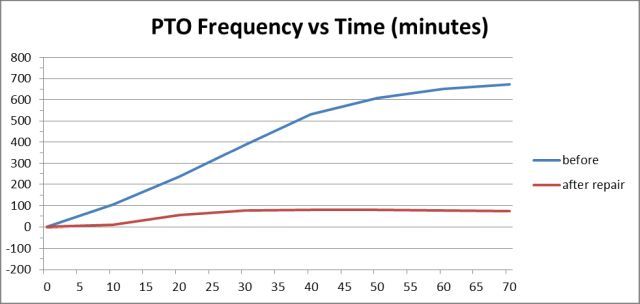

Peter had measured the frequency drift at start-up inside his KWM-2. This is one of the curves in Fig. 1. I mated the PTO with my variable power supply and the initial test of the PTO revealed the following values:

Rising the temperature from roughly 3° C to room temperature (23° C) produced about 500 Hz frequency drift and it took about 60 minutes to reach a more or less stable output. During this interval several small and irregular jumps in frequency (each about 50 Hz) were to be heard and measured.

Next step was to take the PTO guts out of the aluminum box. And again the excellent article (*1) on PTO repair by Jim Miller, N4BE was consulted. Once you have done this two or three times, the whole procedure becomes quite easy and you don't have to plan each step any more.

After disassembly the parts were checked, replaced and function tested in this order:

After all this the PTO was reassembled inside the box, the spindle was thoroughly cleaned and fresh lithium grease was applied. Then the PTO was pre-aligned to ease alignment after inclusion into the KWM-2.

But at this very moment it became clear that trimmer C308, which had not been touched before, was indeed faulty. It was not possible to set the USB/LSB frequency shift. Upon closer inspection some traces of lacquer were visible. Someone had probably tried to "lock" the trimmer.

So the PTO had to come out of the box again and trimmer C308 was disassembled and cleaned, following the instructions given by Glen Zook, K9STH (*2). After that it was again possible to adjust the USB/LSB frequency shift to about 2.7 kHz.

Then the PTO was finally assembled within the box and after pre-alignment the following figures were taken:

The slightly smaller output voltage can be attributed to the less strong coupling of the tuned circuit to V301 (50 pF instead of 200 pF).

When the PTO had returned to Denmark and was put into the KWM-2, Peter took another set of values for frequency drift. This is the second curve in Fig. 1, and indeed frequency drift has improved very much.

And as frequency jumps have disappeared, it can therefore be stated that the intended goal of servicing has been reached.

|

| Fig. 1 PTO frequency vs time |

|

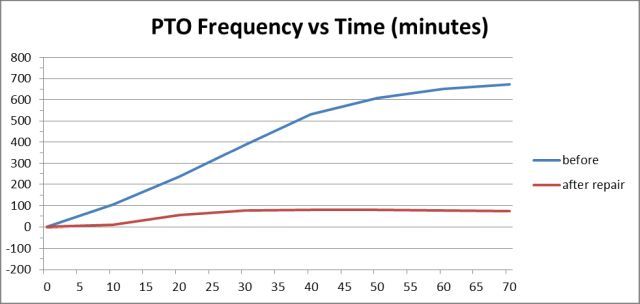

| Fig. 2 Look into the PTO before servicing |

|

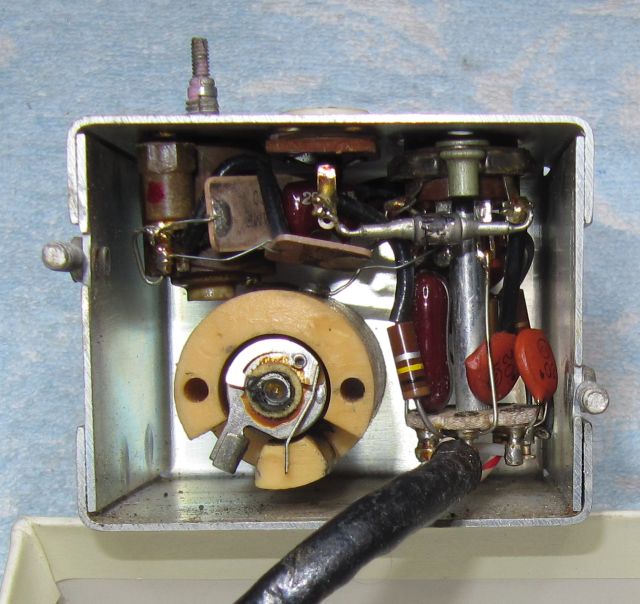

| Fig. 3 Look into the PTO after servicing |

A few remarks should be added as far as the innards of the variable inductor are concerned. While the PTO itself may be considered the "heart" of a KWM-2 or S-line rig, the little core with two riveted pieces of metal is the most ingenious part of a Collins 70K-2 PTO.

The u-shaped member rests against one of the slots in the plastic covering the actual inductor and thereby ensures smooth axial travel of the core when the spindle is turned clockwise (as seen from the front). This would not work when turning ccw, so here comes the second, thinner piece of metal. It serves at least three purposes: the left arm (see Fig. 4) rests against the second slot in the plastic cover and ensures that there is no backlash when going from cw to ccw direction. The little nose at the other arm protrudes right into the groove to the bottom of the spindle and determines the exact position of core versus spindle. And finally, this arm is bent upwards and its springy action keeps the core on a defined axial position.

Upon reassembly it can happen that the little nose is not engaged in the correct groove and consequently there is not enough spring action in axial direction. Fig. 4 shows the correct position when the spindle is just being inserted.

|

| Fig. 4 Metal and spring assembly at the PTO core |

Parts used for replacement:

*1 http://www.collinsradio.org/70k-2-stability-service/

*2 http://www.collinsradio.org/wp-content/uploads/2015/05/Repairing-Frozen-Trimmers-Zook-Copywrite.pdf