Introduction To The British Gin Trap

By Andrew Westcott

-- Links to other pages I've written --

Home Page

Amateur Radio

Concert Master

Coxparo

Gin Traps

Grimspound

Rust Electrolysis

National Explosives

Solar Hot Water

Wistmans Wood

Doddi Mines

Rants

Dog Walker

Zombies!

JS Email

Telephone Intercom

Whetstone Mining

Index Of Sub-Sections On This Page:

Gin Traps: a Brief History

Components of a Gin Trap

Examples of Gin Traps

Variations in Design

Humane Trap Designs

Trapping Rabbits

Further Reading & Links

A gin trap is a mechanical device designed to catch an animal by the leg or head using spring operated steel jaws.

Clarification of the law:

Gin traps have been illegal to use in England since 1958, and if you do happen across one which has been set outdoors, remove it or report it to the police or the RSPCA who will investigate. Although setting a gin trap in order to catch an animal is a criminal offence, it is entirely legal to possess these antiques, and to buy and sell them.

Certain types of spring trap are still legal to use in the UK as long as they are set according to strict guidelines, so ensure that any trap you may find is of an illegal type or has been illegally set before you interfere with it, as to interfere with a legally set trap is itself an offence. The Spring Traps Approval Order 2018 details the traps which are still legal to use in England, and under what conditions. Note that the law may be different in other UK countries.

Gin Traps: A Brief History

The word gin is believed to have come from the word engine which was used historically to describe a self-actuating mechanical device. Gin entered our language as a distortion of the word engine, and as is so often the case with the English language, became accepted as a noun in its own right.

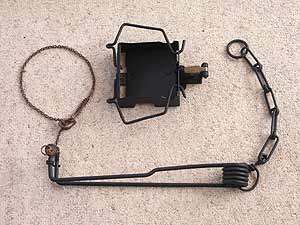

Photo 1

A 4-inch rabbit trap in the set condition: a classic gin

Steel spring traps have probably been in use in some form or another ever since the technique of tempering steel was developed, although one of the earliest indications of a steel trap bearing any similarity to the gin traps described here appears in literature dating from the late 16th century. A wide variety of designs have since evolved based on the target species, ranging from the tiny kingfisher trap through the range of common vermin traps and pole traps right up to the large predator traps, not forgetting the man trap.

Traps are classified by their jaw size, and by far the most common size of gin trap is the 4 inch rabbit trap, which is what most people connect with the word 'gin'. Huge numbers of these were made by all of the trap makers and sold to gamekeepers, professional trappers, farmers and the like to help with the control of rabbits, with many more being exported around the world.

The following laws are part of the history of trap-making in the UK:

1827

A bill was passed banning the use of spring guns and man traps designed to injure, which were intended to be used on large estates to deter poachers, but also had the unfortunate effect of catching and injuring innocent members of the public. They were, however, allowed to be used after this date in a house between sunset and sunrise. The humane man trap was developed to get around this law as it was designed to restrain a person without injury, but even these were eventually outlawed.

1904

It became illegal to set a trap in an elevated position with the intention of catching birds, this doubtlessly having an affect on the manufacture of pole traps intended for this purpose although it is interesting to note that many manufacturers continued to offer 'round traps' after this date, so we can only assume that they expected some purchasers to use them illegally.

1958

On the 31st of July 1958 after a 4-year amnesty period, it became illegal in England (1971 in Scotland) to use any kind of trap designed to restrain an animal by the leg using steel jaws, and the only spring traps allowed to be used after this date were those which had been approved as being humane, which required them to be of the instant kill variety, and then only when set according to strict rules.

Although this last law pretty much killed off the trap-making industry, it was already in serious decline as a result of the arrival of myxomatosis, a virus which was highly infectious and generally fatal to rabbits. It is suspected that the disease arrived in the UK from France during 1953 and so devastating did it prove to be that an estimated 99% of wild rabbits succumbed to the disease in the early years. Obviously, with the much reduced rabbit numbers, there was no longer the urgent need to control them by trapping, therefore trap sales fell drastically.

Some of the more forward-thinking businesses focussed their attention on other ironmongery in an effort to survive, notably E. Tinsley, who still manufacture a range of steel hardware.

Many antique traps of various designs still survive, some safely preserved in collections but no doubt many more are hidden away in a dusty corner of an old shed awaiting discovery, or to slowly rust away.

Back to top

Components Of A Gin Trap

The classic gin trap design is simple and effective, consisting essentially of a pair of jaws held closed by spring tension, and a triggering mechanism. This design has been well proven in the field and is a masterpiece of simple mechanical efficiency. The two diagrams below illustrate the component parts of a typical gin trap; the names I have used for the components are those used by the manufacturers of the time.

Diagram 1

The component parts of a typical gin trap

Diagram 2

Detail of the trigger mechanism

Gin traps are usually described by stating a size, such as 4-inch, 6-inch and so-on, which refers to the jaw size and is related to the size of animal it was designed to take. The diagram below shows where the jaw measurement is taken, and as can be seen this is actually between the insides of the two jaw supports, rather than the jaws themselves, and the measurement is always in inches and fractions of an inch.

Diagram 3

How a trap's size is measured

Examples Of Gin Traps

The 4 inch rabbit trap is by far the most common gin trap to be found, but the system of spring-operated jaws was so efficient that many different designs were made, and in a range of sizes for different animals.

The Standard 4-Inch Rabbit Gin

Photo 2

A 4-inch rabbit trap

The trap pictured above is a classic rabbit trap with 4 inch jaws and an overall length of about 11 inches. It is in good condition as it spent decades in a shed painted in aluminium paint, which protected it from rusting. It features a machine-made spring and a brass tongue and till, and this quality of trap was sometimes referred to as a 'dorset trap', although that term was often misused to increase sales of lower quality traps.

6-Inch Fox Trap

Photo 3

A 6-inch fox trap

The trap above, although very similar to a rabbit trap is somewhat larger, having 6 inch jaws and an overall length of about 16½ inches, and in this case has a machine-made spring and a steel tongue and till. A larger trap such as this would have been used to catch foxes and possibly badgers, and the holes in the plate were for attaching bait.

A Pair Of Vermin Traps

Photo 4

Two smaller gins, a 2½ inch and a 3 inch trap

The two traps pictured here are smaller than a typical rabbit trap, the top one having 3 inch jaws and the lower one 2½ inch jaws with overall lengths of 9½ inches and 8½ inches respectively. The 3 inch trap could just about be used for rabbits, but both were intended for the smaller ground vermin such as stoats, weasels and rats.

A Bird Trap

Photo 5

A small gin trap with 2¼ inch jaws, for catching mice and small birds

The trap above is known by some as a bird trap, and is pretty much the smallest gin trap made in this style. It uses a flat spring and has finely serrated jaws, and is only about 7 inches long. It would have been used for catching mice and small birds, having insufficient strength to hold anything larger, such as a rat.

An Unidentified Trap

Photo 6

A trap of unknown identity, intricately made

I'm showcasing the trap above as it is a rather unusual one, in as much that the quality of workmanship is way beyond what is actually required to do the job. This trap originated from Scotland, and measures about 17½ inches long with a jaw size of 5¾ inches. I have seen others from that region that look vaguely similar, but nothing anywhere near as elaborate.

Photo 7 shows the underside of the trap, showing how the bridge has been carefully merged into the stock, creating essentially a single piece of iron rather than the riveted design usually seen.

Photo 8 shows detail of the tongue, and again, it has been carefully shaped rather than just a flap of iron or brass as is normally the case.

Photo 9 shows the hole for the chain. Rather than just punching a hole in the stock bar, the end has been carefully wrought to form this loop.

The stock bar itself has been carefully shaped too rather than just using an iron bar as is normal, and the inner jaw standard and the spring attachment have been threaded and secured using a square nut. Even the jaws have been carefully made to ensure they meet perfectly. I can't help thinking that this was perhaps a trap made by a blacksmith or his apprentice as a test piece or to show off his skills, as just about every skill a blacksmith should have has been demonstrated, including making a thread and tempering a spring. I really can't imagine that anyone would go to so much trouble just to make a trap for normal use.

Pole Traps

Photo 10A pole trap with toothed jaws |

Photo 11A pole trap with smooth jaws |

Pole traps were intended for catching birds and are an interesting variation of the gin trap in as much as they are designed around a circular base to allow them to be set on the top of a pole or tree stump, hence their name, and as with other gins they came in a range of sizes. Photo 10 shows a fairly large pole trap with 5 inch toothed jaws, and Photo 11 shows one with smooth jaws, a feature believed to reduce a bird's injuries.

Birds of prey were considered unwelcome by gamekeepers as they were known to kill young game birds so it would be noted where a bird would regularly perch, and a trap set accordingly. The bird, upon landing on the top of the pole would trigger the trap and be caught by the legs.

Kingfisher traps were the smallest pole trap manufactured in the UK and typically have a jaw measurement of just 2 inches, and this small size is illustrated by the one pictured sitting on my hand in photo 12.

Kingfisher traps, as the name may suggest, were used to trap kingfishers, which if present in sufficient numbers were perceived as a threat to fish stocks, although it is difficult to imagine such a tiny bird doing any real damage.

Taxidermists of the time also expressed an interest in the colourful birds, and without doubt many were caught to end up in display cabinets or to have their feathers used for fishing lures. Due to their highly specific use, kingfisher traps are uncommon although they do turn up for sale from time to time.

Large Predator Traps

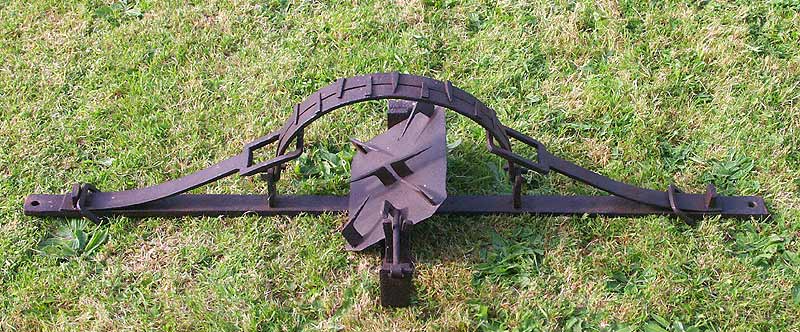

Photo 13

Not a man trap!

A large predator trap with double springs & 16 inch jaws

The impressive beast shown in photo 13 is a rather more substantial gin trap intended for large predators and measures around 4 feet long with 16 inch spiked jaws. Examples of these can occasionally be seen in museums described as man traps, and although there is no doubt that the trap is large enough to catch a person by the leg, this is not its intended function. Photo 14 shows a trap of similar design, but with slightly smaller jaws and a single spring.

Photo 14

A large predator trap with single spring & 14 inch jaws

It is generally accepted that these traps were designed to catch the predator by the neck as it investigated the meat the trap would have been baited with, which is why the plate is of the 'treadle' design, meaning it tips one way or the other to release the tongue, springing the trap. The picture below is dated 1814, and despite the rather poor interpretation of the trap, it clearly shows a wolf caught by the neck.

An 1814 painting of a wolf caught by the neck

Original source unknown

Regarding man traps, there are some ways of determining that these aren't man traps: note the plate or treadle in the top example which sports some vicious-looking spikes; they are there purely for the purpose of securing a piece of meat or the carcass of a small animal in place to act as bait: obviously not a required feature on a man trap. Similarly, the second trap has holes punched in the plate for the same reason: securing bait.

True man traps tend to be quite flimsy in build compared to predator traps, simply because a trapped man doesn't struggle and pull at the trap in the same way that an animal would. Some man traps incorporated a ratchet and locking mechanism to prevent the victim or his companions opening the trap.

A humane man trap

Photo used with permission: Horniman Museum & Gardens

The photo above shows an example of a humane man trap, designed to capture and restrain a man without injury. There are no toothed jaws in this case, just a pair of bars which close against the lower leg, stopping the victim from withdrawing his foot. There is a locking ratchet assembly to prevent victims releasing themselves, meaning they would have to wait until the gamekeeper arrived to release them.

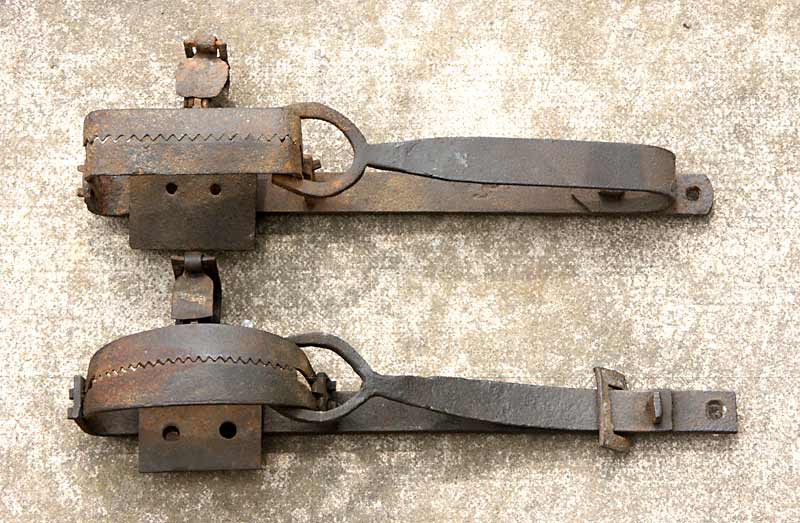

Run Traps

Photo 15

A pair of run traps for small ground vermin.

Around 11 inches long with 4 inch jaws

Photo 15 shows a pair of gin traps of a specialised design, known as run traps. They were used to take small ground vermin such as rats, mice and weasels and were offered by most of the trap manufacturers. A typical jaw size for these traps would be three to four inches or so.

Characteristic of this type of trap are the small saw-like teeth cut into the jaws and the holes in the plate to allow the fixing of bait. They most commonly have rounded jaws and a flat spring which allowed them to have a low profile when set; the top trap in this photo is less common, having square jaws and a bow spring.

Back to top

Variations In Gin Trap Construction

There are a great many variations in the design of gin traps and the methods used to manufacture them, and the first variation I'll deal with here concerns the design of spring used.

Photo 16An example of a flat forged spring |

Photo 17An example of a coiled wire spring |

In the early days of trap manufacture, springs were entirely hand-made, being heated in a forge and beaten into shape on an anvil before being subjected to some rather dubious hardening and tempering techniques, resulting in a type of spring known interestingly enough as a forged spring. The earliest traps used what is known as a flat spring as shown in photo 16, which was all but superceded by more efficient types, although this design was still being incorporated into certain small vermin traps and even the largest lion traps as exported to Africa right up until production ceased. The early flat springs had a reputation for rapidly becoming weakened, although I strongly suspect this had more to do with the poor tempering techniques rather than a basic design problem.

A later modification consisted of folding the spring over by 180° to create what is known as a bow spring, this enabling a longer spring to be incorporated into a physically shorter length. This design of spring became pretty much the industry standard throughout the trap making years, and proved to be more effective and resistant to wear than the old flat springs.

The final evolution occurred with the introduction of the coiled wire spring, as shown in photo 17. This design uses a rather more modern looking spring than the others, made as it is of stout spring steel wire wound into a coil, one end being anchored onto the stock end, the other formed into a loop to create the eye. This idea had important benefits over the other types in that it was more resistant to weakening by use or rust.

Photo 18The forge welded join on the underside of this spring can be seen |

Photo 19This machine-made spring has no join, and is convex to increase strength |

Photo 18 shows an old style forged spring. The method of producing forged springs may be of interest so I'll describe it briefly here: initially a bar of spring steel would be obtained, and a piece of cheaper ordinary iron would be forge welded onto the end of it. With a great deal of work with the forge and hammer the iron end would be split, opened out, and the two resulting prongs bent inwards again to form the spring's eye, and worked to obtain the required shape.

This process required many heating phases, was very time consuming and produced springs which although similar to look at, were all unique in their own small way, but at the time it was the only way to get the job done. As can be seen in the photograph the welding of the two parts of the spring often leaves a noticeable join mark on the underside of the spring. Once finished, the newly formed spring would be heated to orange heat, then quenched in water to harden it. It would then undergo further treatment to produce the required springiness by reheating the spring to a specific temperature for a certain length of time to 'draw the temper', a mysterious and critical process little understood by those outside the industry.

Over time, trap manufacturers became aware of the benefits of making some of the trap parts by machine and many of the larger companies invested heavily in the equipment to do so, with only the smaller companies being forced to continue down the hand-made route. Photo 19 shows an example of a spring which has been stamped out and shaped by machine, and as can be seen it is dished upwards in cross section (embossed) to reduce flexure at this point, and there is no evidence of the join found on forged springs. Machine-made components led to improved quality and uniformity which meant a better product.

Photo 20

Ridged and flat jawsThe ridged jaw design was more resistant to bending but more expensive to make

Another way traps can vary is in the design of the jaws; some may have teeth cut into the edges, have spiked teeth riveted on the top surface or underside, and where the teeth are stamped as part of the jaw itself, there is variation in the form, such as whether or not the teeth are fully interlocking or only partly so and some jaws are smooth with no teeth at all.

However, despite so many differences in design, jaws can be sub-divided basically into two main categories, those that are either flat or those with a reinforcing ridge, both types being shown in photo 20, with the ridged jaws on the left and the flat jaws on the right. The ridges were incorporated as reinforcements to the jaws making them less susceptible to flexing, but as this shape had to be specially created the costs were somewhat higher and this design feature was usually limited to the more expensive and better quality trap.

Some traps were designed in such a way that a small gap would be left between the jaws when fully closed as in photo 21, and such traps were described as having 'offset jaws'. This feature, although commonly seen in American traps is very uncommon in British traps and very few manufacturers incorporated the idea. The feature can be found on some versions of the once popular and still very common 4 inch 'LI-LO' wire spring trap.

Offset jaws would be considered a good idea for a number of reasons depending on who you asked. One view is that it was considered more humane to not have the jaws slam completely shut on the leg, breaking bones and cutting skin, the intentional gap reducing this. Another view was again concerned with leg damage but for a different reason, the intention being to minimise the damage to the leg bone and tissue which in turn reduced the chances of the animal pulling its leg off completely and escaping, albeit to probably die later.

Photo 22

Robert's 'Dogless' trapThe Roberts Dogless design, which eliminates the need for a tongue (or dog)

Several interesting variations can be found in the trigger mechanism. One feature of the better class of trap was the use of a brass tongue and till rather than having these components made out of steel, the benefit of this was chiefly to eliminate the chances of the mechanism rusting up if left set for any length of time, but also a brass trigger mechanism had a smoother action, the brass pieces sliding smoothly over each other rather than grating as rusted steel components would tend to do.

On occasion, the avid gin trap collector may be fortunate enough to encounter a rather different style of triggering mechanism to that normally fitted to a gin trap, as several manufacturers experimented with trying to simplify or improve the mechanism in order to either boost performance or to reduce costs. Many interesting ideas were tried and incorporated into production models and one such idea was that patented by Roberts in 1932, and photo 22 shows one such Roberts Dogless trap which in this case involved the elimination of the tongue, or 'dog' as it is known as in America, and relied on the opened jaws engaging an elongated till directly. The advantage of this design was that the trap was simpler and therefore cheaper to manufacture, lighter and narrower in the bridge, and easier to set as only the plate had to be lifted into position.

Photo 23

No bridge or tongueThis gin trap design has eliminated not only the tongue, but also the bridge

The trap pictured in photo 23 shows another approach to designing a trigger mechanism which went a stage further than the 'dogless' design. This trap is a typical 'run trap' having a flat spring and a jaw measurement of 3¼ inches, but is unusual in that not only does it have no tongue, but it has no bridge either, the plate being mounted directly to the stock and the till on the plate being positioned to engage directly with the eye of the spring, simplifying the design pretty much as far as was possible.

The advantages were similar to the previous example and with fewer parts to make and assemble, the trap was cheaper to manufacture and presumably cheaper to buy. One disadvantage of this design was the high force placed on the till by the spring, as it didn't benefit from the force being divided down by the action of the leverage of the jaw and tongue assembly, resulting in a high wear rate. There was also no scope for adjustment in the trigger action and once worn, the trap became virtually useless. Despite this design possibly being cheaper to buy, I can only assume that they had certain operational issues in the field as they were never widely accepted by trappers of the day and relatively few were manufactured in comparison to the conventional tongue and till arrangement.

Photo 24

An extended stockThe trap on the right has an extended stock to help protect the mechanism if dropped

Another variation on the normal trap design which a novice trap collector may overlook is the extended stock. An example of a trap made with an extended stock is pictured in photo 24 with a conventional trap on the left and the extended stock on the right.

This design is a departure from the usual practice of bending up the stock head to form one of the jaw standards, and instead the stock remains straight and a second standard is fitted on which to hinge the jaws.

This construction method leaves a small amount of stock bar protruding, and according to various adverts of the time had the benefit of offering added protection to the jaw mountings in the event of the trap being dropped end down. Presumably this happened frequently enough to justify the extra cost of manufacture and purchase, and it seems several manufacturers offered this option.

Back to top

Chains, Swivels and Stakes

Any gin trap would have required some form of securing to prevent the captured animal or a predator dragging the trap away causing it to be lost, and the usual way of achieving this would be to chain it to a wooden or metal stake driven into the ground, the chain usually supplied already attached to a new trap. The chain would need some kind of swivel link along its length to allow the chain to twist as the unfortunate animal struggled to free itself, as if the chain became kinked it might be possible for the chain to be broken or the stake be levered out of the ground, resulting in the loss of both the captured animal and the trap.

Photo 25Gin trap chains come in a variety of designs, as do their swivels |

Photo 26Gin trap stakes vary greatly in design, ranging from metal pins to wooden pegs |

Photo 25 shows three different styles of swivel often found on trap chains, the top one being the most common twisted wire design, the middle being a more expensive and stronger cast type and the bottom is an example of a 'box swivel', patented by Lane's and found on some of their wire spring traps, amongst others.

Photo 26 shows a random selection of stakes fitted to gin traps, and here it is possible to get an idea of the wide variety of designs and styles to be encountered, some supplied with the trap, others home-made. The top three stakes pictured are made from steel, the longer lengths useful for securing a trap in sandy soil.

The odd one out here is the bottom stake which is made out of wood. This stake was probably home-made, and although it may have been inferior in strength and would have had a shorter useful life as compared to the steel one, certain opinions suggest wooden stakes were in fact more secure, being more difficult to pull from the ground on account of their extra width.

Back to top

Examples of Humane Trap Designs

Although the conventional gin trap reigned supreme for catching rabbits, there was considerable concern about the suffering they caused. As a result, some designers and manufacturers experimented with a more humane approach, most intended to instantly kill the rabbit rather than leave it suffering in a leg-hold trap.

Photo 27 shows a Douglas Improved humane rabbit trap and you can see it shares some components with a gin trap. This trap differs in the way it catches rabbits: the spring is depressed and held in position by the familiar till and tongue arrangement. The outriggers either side of the plate act as anchorage points for a replaceable length of wire which would be formed into a loop. When the trap was set into the ground in the manner of a regular gin trap, the loop would protrude through the slot in the crossbar at the end of the spring, and the wire would be adjusted to merge into the undergrowth.

On being sprung, the crossbar slot would rise up the loop of wire, trapping the rabbit between it and the top of the loop. An old trapper I used to be in communication with (sadly now deceased) told me that he used 14 gauge copper wire for the loop as it was easy to fasten to the anchors and to bend into position when setting the trap. He said he didn't get on well with this design, and preferred a conventional gin trap; indeed, William Carnegie wrote in his book, "It was a very good trap as far as theory went, but possessed little or no practical value." Not many examples were made of this trap, and it does seem that it never became popular with the trappers of the day.

Photo 28

The Everitt rat trapThis trap would have been set against a wall or similar, baited or unbaited, to catch rats

Photo 28 shows another adaption of the traditional gin trap maker's skill to create a humane trap. This is the Everitt rat trap, stamped on the neck of the spring with H. LANE, the manufacturer. As can be seen, this trap features the familiar gin trap style spring, plate and till, but instead of closing a pair of jaws, the eye is fixed to a pair of serrated prongs which rise within slots in the galvanised steel artificial tunnel.

Rats tend to move around in relative security by keeping close to walls and other such boundaries, and this trap would be set with the prongs facing a boundary where a potential run may be, there would not necessarily be any bait involved. The rat would pass through the artificial tunnel whilst out foraging, pressing down the plate as it did so. This would release the spring which would rapidly lift the prongs to the roof of the tunnel, trapping it against the roof.

I understand that these were fairly popular and effective against rats, weasels and stoats, but apparently did not have an overly long operational life if left outside due to corrosion of the sheet steel forming the artificial tunnel despite the galvanising, therefore good examples are becoming somewhat thin on the ground.

Humane trap designs weren't always required to kill the target animal and a live catch was seen as preferable by some people, resulting in some interesting ideas, one of which was the Phelps Leg Snare, patented in 1933.

Photo 29 shows a nice complete example of a Phelps Mk2 leg snare, with most of its paint intact. The powerful spring would be held compressed using the tongue, till and plate system until an animal stepped on the plate, whereupon the spring ends would be released pulling the noose, which was laid on the supports around the plate, tight around the animal's leg. As the trap came in two parts it was easy for one part to be mislaid, and it is rare to find a complete one these days.

Photo 30 shows detail of the noose chain, with the penny for scale. As can be seen, the noose chain complete with its tiny swivel appears very fragile, almost jewellery-grade in nature, so I would suspect that breakages were common. The chain passes through the brass loop to form the noose, and the other end has a brass washer and split ring to secure it to the other end of the sprung arms. The split ring can be moved up the chain to facilitate adjustment, ensuring the rabbit was held securely but not injured.

Once the legislation of 1958 had come into force and conventional leg-hold traps had been outlawed, trappers had to use one of the few designs approved under the Spring Traps Approval Order in force at the time, and most of these designs favoured the method of clamping the body of the target animal between a pair of spring loaded arms or jaws, this method proving to be effective in catching the animal and also of ensuring a quick kill.

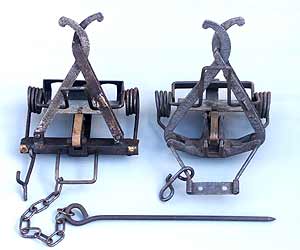

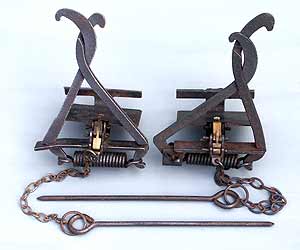

Photo 31A pair of humane instant-kill Juby traps, the Mk1 on the left and the Mk2 on the right |

Photo 32A pair of humane instant-kill Juby traps, the Mk1 on the left and the Mk2 on the right |

Such a trap is the Juby trap, and photo 31 shows two models, the Mk1 and the Mk2 with the Mk1 on the left. A look at the high resolution image will reveal the differences between the two versions, the main differences being the rather more complicated and prototype-like assembly found in the relatively rare Mk1, such as the way the ends of the coiled springs are brazed to the angle-iron base, the hinges for the jaws are welded to the base, and a lug is welded on to the right-hand arm. Also, the safety catch is a welded construction rather than simply bent wire.

The Mk2 version has been adapted for high volume production by using a cast base and the jaw hinges making use of the ends of the springs as they pass through holes in the base. The jaws are also cast or stamped, and bear part numbers visible in the photo. The Juby was, despite the modifications seen here to ease production costs, a fairly expensive trap to produce but highly effective in the field.

A cheaper alternative to the Juby was the Imbra trap as shown in photo 32. Broadly similar in design and appearance and easily confused if you are unfamiliar with the differences, this trap was easier to manufacture and lighter in the field, but proved equally effective. Pictured here are two versions of the Imbra, once again the Mk1 and the Mk2, with the Mk1 on the left. There are only minor differences this time which represent streamlining in manufacture and the most obvious is the change to the way the left-hand jaw is hinged, and the spring being attached to one jaw only. The earlier Mk1 relied on spring force to keep the jaws located with the possibility of them becoming misaligned, but this had been rectified in the Mk2 by using a cotter pin to locate the jaw at the fulcrum. The right-hand jaw in both versions has a slot which the other jaw passes through, similar to the Juby.

Photo 33A Mk1 Sawyer rabbit trap, an early humane design intended to instantly kill the rabbit |

Photo 34The Fenn Mk1 humane trap, designed to instantly kill the rabbit. Later models had square jaws |

Photo 33 shows a Sawyer rabbit trap, in this case the Mk1 version. Once again it uses the tried and tested configuration of two opposing spring-loaded jaws to catch and kill the rabbit. In 1874 the RSPCA, in the first of several competitions launched in an attempt to speed up the emergence of a truly humane killer trap offered an initial prize of £50 to anyone who could design a suitably efficient device.

Many designs were offered over the years for testing but it was eventually the Sawyer trap which finally won the competition in 1946, taking the prize which then stood at £300. It is an elegant trap of lightweight construction although not overly common these days as corrosion takes its toll over the years.

Photo 34 shows an early rabbit trap marketed by Fenn: the Fenn Mk1 rabbit trap, the only rabbit trap on this page still legal to use. This trap wasn't made for long and is now relatively rare, especially in this condition. It used rounded jaws as can be seen, which would be opened up to set the trap. Once triggered, the jaws would clamp hard around the rabbit's body, rapidly killing it.

The ongoing war against vermin has given rise to some ingenious trap designs, probably none more so than in the area of mole control. Moles are very secretive and because of their habit of living an almost entirely underground existence, special trap designs had to be designed to destroy them.

Photo 35

An Anglo Impassable mole trap: the Mk1

Photo 35 is of an interesting design of spring mole trap known as the 'Anglo Impassable', the Mk1 in this case. For reference, the main difference between what collectors refer to as the Mk1 & the Mk2 is that the top of the spring rod of the Mk1 is bent around to form a loop, whereas in the Mk2 the loop is complete and of forged manufacture.

Moles often create a run just under the surface of the grass raising the turf as they do so, and if a small section is flattened with the foot, next time the mole travels the tunnel he will re-open the tunnel by re-lifting the turf, and this trap makes use of this fact. The assembly bearing the six sharp spikes would be drawn upwards against the coil spring, being retained by a plate and lever assembly. The trap's two ground spikes would then be pushed into the soil either side and directly above the flattened mole run in such a way that the trigger plate would rest on the surface of the flattened run.

When the unfortunate mole attempted to push through the flattened section of tunnel the trigger plate would be lifted, releasing a catch which in turn would release the six spikes which would slam down guillotine style through the ground impaling the victim in its tunnel, quickly killing it. This trap didn't find favour with professional mole catchers as the spikes would damage the pelt, rendering it worthless.

Photo 36

A scissor style mole trapThis type of mole trap is still used today and kills the mole when the jaws close on it

Photo 36 is of a conventional humane mole trap. This type of trap is fairly common and legal to use, and the design has changed little over the decades so it can be difficult distinguishing the old from the new as condition alone can be a poor indicator of age. The main variations to be seen are in the design of the spring, the example here having a coiled compression spring, but most often seen are the types with two flat springs acting against each other.

To set a trap of this design you simply squeeze the handles together to open the jaws and insert the trigger ring between them to keep them apart. The trap would then be placed in a partially excavated mole run, and when the mole encountered the ring, it would try to force itself through it, dislodging the ring from between the jaws allowing them to close, crushing the body of the mole resulting, hopefully, in near instantaneous death. This was a bloodless method of dispatching the mole, leaving the pelt in good condition.

Back to top

Using The Gin Trap Against Rabbits

The classic gin trap could be set either at the entrance to burrows or in the runs, but successful trapping relied on the trapper understanding how to correctly deploy his traps, and in the main this required the trap to be hidden from view. This would generally be achieved by excavating an area of earth just large enough and deep enough to allow the set trap to sit within the recess, which would then be gently concealed by sprinkling earth over it to bring the surface back up to its original level, completely hiding the trap. Rabbits tend to leave their burrows in a predictable manner, positioning their feet in precisely the same place time after time, so an experienced trapper would set his traps in such a way that the plate of the trap coincided with where the rabbits' feet would touch the ground.

I was born some time after gin traps were made illegal to use and so have no direct knowledge of the lifestyle or methods of a typical trapper, but there are books available which help give an insight into how gin traps were used. Far more interesting though are those who remember first-hand how it was done, and I consider myself fortunate to have been in contact with such a person, a Mr Robin Menneer, who has written much on the subject of Cornish hedges, and in so doing has highlighted the specific damage rabbits do to these structures by way of their excavations. I quote, with permission, a section from one of his papers which gives an insight into the life of a professional trapper:

"The author himself, like many another country boy, caught rabbits with gin traps during the war, when food was rationed. Traps used to be set along a length of hedge, with a trap in every run and at the entrance to every hole. Each trap was set into the ground so that its top was level with the surface, the spring covered with thin turf and the foot plate with sifted earth. Most rabbits were caught during the first night and, after a day or two, the traps were moved on. In this way, the farmer hoped that all the rabbits in that section of hedge would be dealt with. But, once all was quiet again, rabbits moved in from other untrapped hedges. Naturally it did not pay the trapper to move his traps to a hedge until it had plenty of rabbits, so really he was only reducing the population, not eliminating it."

"Most farmers employed rabbit trappers to reduce the numbers of this pest. Otherwise, with their small fields, they would often find that half their grass and corn had been eaten by rabbits coming out of the hedges. Len Neale told the author how in his youth he helped his father move his 900 gins on farms at Trewint. They picked up and re-laid 300 traps each day, Monday to Saturday, so each gin was moved on average every third day except Sundays, when they were only looked at, rabbits removed and the traps re-set in the same place. The rabbits were sold to a local dealer who put them on the train."

Robin includes a table of Mr Neale's trapping records, which

"shows how relatively few rabbits (5.6 per trap per year) were caught by the 900 gins which had to be taken up and re-set in a new place every third day."

He notes that

"Trapping was not an easy way of making a living."

For far more detail and information on rabbits I recommend a visit to Robin's Cornish Hedges web site, where his paper (in PDF format) entitled "The Curse of Rabbits in Cornish Hedges" can be found under the "Cornish Hedges Library" heading.

Back to top

Selling A Trap? How To Measure And Describe It

I don't consider myself to be any kind of expert on traps, but I do have a reasonable selection of examples which I have amassed over the years and I'm always on the lookout for additions to my collection. If you have a trap to sell, send me some decent photos of it to my email address at the bottom of the page and maybe we can haggle over what we think it's worth.

Diagram 3

Measuring a trap's jaw size.

If you are considering selling a trap, please resist the temptation to set it as there is a distinct possibility that a very old and rusty spring may break if depressed or stay permanently bent, and either will seriously impact its value. A trap which has been repeatedly set and triggered will suffer obvious damage to the sides of the jaws, and collectors won't be very interested in a trap with such damage.

When describing the trap, include the jaw measurement: I've repeated this diagram from earlier in the page to show where the jaw measurement should be taken, and as can be seen this is actually between the insides of the two jaw supports, rather than the jaws themselves, and the measurement should be imperial and to the nearest quarter of an inch.

Look for any identifying marks or stampings, these being usually found on the neck of the spring, on the plate, or on the upper or lower surface of the tongue, but don't attempt to clean a trap in any way, as collectors will have their own ideas on how to treat and preserve the trap once purchased; careless abrasion can obliterate remains of name stamps, so just leave it as it is, we prefer it that way, cobwebs and cow poop included.

Back to top

Further Reading

Rural Reflections (2nd Revised and Enlarged Edition.) - Stuart Haddon-Riddoch

A hard back limited edition book, containing 416 pages, index, and over 400 illustrations.

An exhaustive study of British traps, the trap making industry and game keeping. An absolute must for anyone seriously interested in traps and trap collecting.

How To Trap & Snare - William Carnegie

An excellent book running to 224 pages, originally published in 1898, but now available once again. Describes in great detail how a trapper of the time would capture various species of vermin, and for this the original author draws on many years of experience in the field.

Rabbit Traps - T & J Bateman

A pictorial guide to British rabbit traps, and includes examples from the author's own collection. Runs to 53 pages.

Bird Traps - Traps & Scarers - T & J Bateman

A pictorial guide to British bird traps, featuring traps in the author's own collection. Runs to 33 pages.

Related Links

Vintage Traps & Collectables

An online auction site dealing primarily with the sale of vintage traps.

DB Springs

UK manufacturers of the Fenn range of humane, approved traps.

The Trap Man

UK manufacturers and suppliers of humane cage traps.

Cornish Hedges

A web site concerned with perpetuating and 'continuing an ancient craft'. One of the papers deals specifically with the problem rabbits cause to these hedges and contains a wealth of information on rabbits generally, and the methods used to trap them.

If you know of any other trap collecting or vermin related links which could go here, please let me know so I can consider them for inclusion.

Back to top

I can be contacted at this address:

Copyright © Andrew Westcott 2003 - 2025

I'm happy for anyone to use this material for private, non-commercial or educational purposes, but credit to the author must be given. For any other use please contact me for permission.